Analytically pure, chemically pure, reagent grade magnesium oxide is generally very high purity magnesium oxide, its preparation process generally have gas phase method, that is, high purity magnesium metal and oxygen reaction to generate nuclei, and then make the particles to continue to grow, to make high purity micropowder magnesium oxide. Containing more than 80% of magnesium oxide crude raw materials with inorganic acid (sulfuric acid, hydrochloric acid, nitric acid) to the ratio of one to two molar ratio of dissolution, made of magnesium salt of inorganic acid. Refined to remove the impurities, in the oxygen atmosphere under pressure heating treatment, and then washed, dehydrated, dried, heated at 1100 ℃ for one hour, the production of high-purity magnesium oxide. Analytical pure magnesium oxide is mainly used in reagent industry and other chemicals or intermediates.

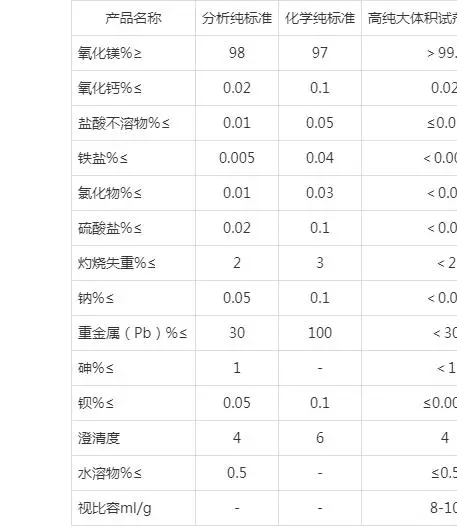

Messi Biology adopts compound decomposition production process, with Tibet water magnesite as the main material, particle processing technology, the product is well dispersed, uniform particle size; the average particle size has a variety of (1-100 micron), the use of a number of decontamination technology, the production of various physicochemical indexes are higher than the reagent grade magnesium oxide standard requirements for the production of large-volume magnesium oxide products, and according to the requirements of customers tailored to meet their products.

High Purity Magnesium Oxide Industry Overview

High purity magnesium oxide is often chosen as a high quality high temperature heat resistant material because of its excellent alkali resistance and electrical insulation ability at high temperatures and excellent light penetration. In ceramics, it is widely used as a basic material for the production of high-transparency ceramic crucibles and substrates; in electrical engineering, it is used as a filler for magnetic devices, as an insulating filler, and as a carrier medium. Compared to alumina, ceramic substrates made of high-purity magnesium oxide have a higher thermal conductivity (about twice that of alumina), and the electrolyte loss is only one-tenth that of alumina. In addition, high-purity magnesium oxide can also be used as a raw material for high-purity electrofused magnesia, and in the chemical field, it is known as “analytically pure” magnesium oxide. Typically, the magnesium oxide content of high-purity magnesium oxide exceeds 98%, which enables it to maintain excellent alkali resistance and electrical insulation properties at high temperatures, as well as excellent light penetration, high thermal conductivity and a large coefficient of thermal expansion. According to different application requirements, high purity magnesium oxide can be subdivided into silicon steel magnesium oxide, electrofusion magnesium oxide, electromagnetic magnesium oxide, pharmaceutical magnesium oxide and single crystal magnesium oxide and other categories.

High purity magnesium oxide is widely used as heat-resistant material in high temperature field for its excellent acid and alkaline resistance, excellent electric insulation property, excellent light penetration, extraordinary high thermal conductivity, and relatively large coefficient of thermal expansion, such as in the ceramic industry as the key raw material for making ceramic glaze, substrate, etc.; at the same time it is also used as a magnetic device, filler material, insulating material, and various types of carrier, etc., in the electrical and electronic manufacturing industry. It is also used in the electrical and electronic manufacturing industry as a magnetic device, filler material, insulating material, and various types of carriers and other purposes. It is worth mentioning that the high purity magnesium oxide of more than 99% has become one of the most excellent chemical synthetic raw materials used to manufacture high quality oriented silicon steel wafers in the current global scope.

Along with the booming development of modern industry, the use of high-purity magnesium oxide in the original traditional applications gradually expand the scope of use, while the exploration and development of new applications are also in full swing. Therefore, the market demand for high-purity magnesium oxide is growing, and its production also rises. With high purity magnesium oxide as the basic raw material, we are able to produce a series of special magnesium oxide products with special applications, such as electrofused magnesium oxide single crystals, high purity electrofused magnesium oxide and nano magnesium oxide. These products have a wide range of applications in instrumentation, electronics, electrical, optical, metallurgy, national defense and aerospace and other fields.