Magnesium oxide as an additive with polymeric sulfur cathode and modified glass fiber separator for high performance lithium sulfur batteries

The lithium ion technology is now beginning to enter into electric vehicles and grid storage of renewable energies (solar and wind energy). However, the current lithium ion technology has reached the limitations of their charge-storage capacity and energy density. Therefore, alternative cathode and anode materials that offer higher capacities need to be developed. Lithium- sulfur battery with sulfur based cathode undergoes conversion reactions while accommodating more ions and electrons as promising options to overcome the charge-storage limitations of lithium ion battery. Cost, cycle life, safety, energy, power, and environmental impact should be considered for commercializing modified lithium-sulfur batteries.

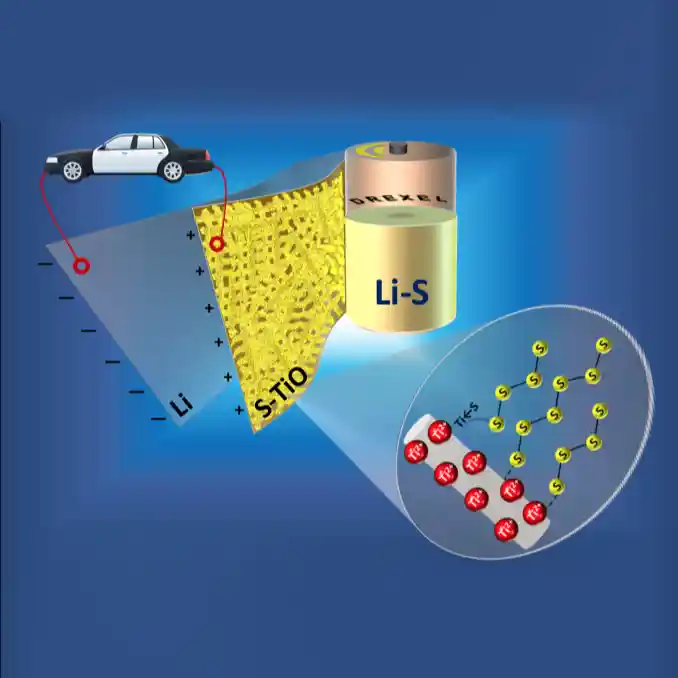

In this study highly conductive and lightweight cathode materials consist of poly 1,5-diaminoanthraquinone (PDAAQ) and magnesium oxide (MgO) have been considered to increase cycle life and performance of lithium-sulfur batteries.

Modified one and double side coated glass fiber separator also was investigated to improve confinement of active materials on the pores and prevented dissolution of undesired materials in the electrolyte. The cells with MgO/PDAAQ/S cathode and uncoated glass fiber separator showed initial discharge capacity of 1000 mAh g-1 at 2C. The discharge capacity decreased at ~ 900 mAh g-1 for 5C. MgO/PDAAQ/S cathode and double side coated glass fiber separator showed the higher capacities of ~1250 and 1170 at 2C and 5C respectively.