Magnesium oxide has good chemical inertness, heat resistance, insulation and thermal conductivity. The most prominent ones are good resistance to high temperature oxidation, moderate alkalinity, electrophilicity due to the presence of oxygen vacancies and single electrons, etc. , these properties provide important prerequisites and foundations for the application of magnesium oxide. One-dimensional or two-dimensional MgO structures, such as nanorods, nanoribbons, and nanowires, have successfully explored a variety of experimental synthesis methods.

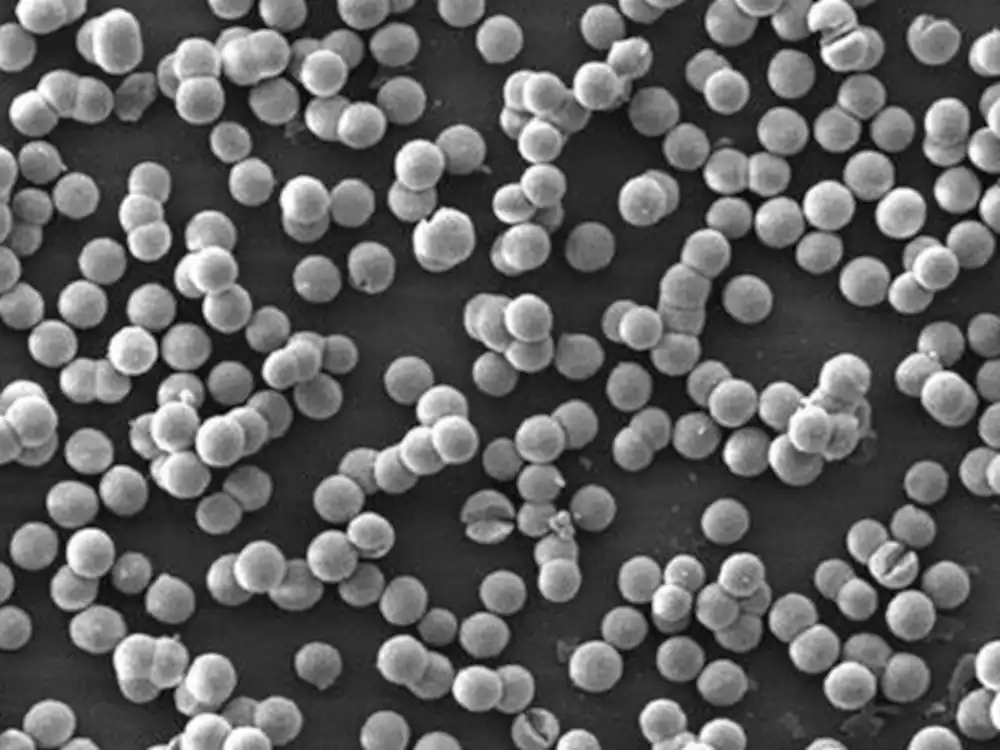

However, there are few reports on the preparation method of three-dimensional spherical MgO, and some special shaped magnesium oxides have been found to have very effective applications in many aspects after research.

Application of spherical magnesium oxide

Spherical magnesium oxide is mainly used in chromatography stationary phase, adsorption of toxic substances, as material additives and other fields.

1.Chromatography stationary phase

High-performance liquid chromatography and its effective separation effect and chromatography in the use of packaging materials, that is, the stationary phase has a very close relationship. Nowadays, the packaging materials for liquid chromatography are mainly silica and packaging materials based on it, but it also has the problems of poor stability, reaction with some basic substances and difficult separation.

The mixture of magnesium and aluminum oxides and silica in a certain proportion as a stationary phase for liquid chromatography can solve this problem well. Compared with traditional silica as stationary phase, spherical magnesium oxide has high selectivity and high efficiency for the separation of basic chemicals, so the application of spherical magnesium oxide in liquid chromatography is getting more and more attention.

2.Spherical magnesium oxide adsorption of pollutants in water

The mesoporous nanosheets of spherical magnesium oxide show excellent adsorption performance, which can adsorb common toxic heavy metal ions and organic pollutants, and are promising to be applied in wastewater treatment process.

3. Spherical magnesium oxide as an additive for polymer materials

The flame retardancy of general plastics is very low, and accidents can easily occur. For example, in the LED lamp, if used for a long time, the temperature inside the lamp will be very high, if the heat can not be released in time, then it is easy to have an accident. Generally some inorganic substances are added to the plastic to improve the thermal conductivity of the plastic. The general flame retardants are zinc borate, aluminum oxide and magnesium oxide.

Generally speaking, alumina and magnesium oxide are easier to get, but the preparation process of spherical magnesium oxide is not too mature, so now alumina is the widely used flame retardant additive. But the high performance of spherical magnesium oxide flame retardant makes the industry very optimistic about its prospects.

Preparation of spherical magnesium oxide

Spherical structure of magnesium oxide is calcined from precursor spherical basic magnesium carbonate or spherical magnesium hydroxide or spherical basic magnesium oxalate. Taking spherical magnesium alkali carbonate as an example, the spherical structure of magnesium alkali carbonate is stacked by the sheet structure of magnesium alkali carbonate, calcining the line of magnesium alkali carbonate, the spherical magnesium alkali carbonate undergoes thermal decomposition, and obtains the spherical magnesium oxide. The synthesis method of spherical magnesium carbonate can be divided into direct synthesis method and indirect synthesis method.

1. Direct synthesis method

The direct synthesis method is the more widely used synthesis method in the preparation of spherical basic magnesium carbonate. This method is a direct synthesis at a specific reaction temperature, no longer change any experimental conditions, directly obtain the spherical basic magnesium carbonate.

(1) SDS-assisted low-temperature synthesis method

Taking magnesium chloride and sodium carbonate as experimental raw materials, spherical basic magnesium carbonate was directly synthesized under the assistance of sodium dodecyl sulfate at a temperature lower than 55 °C. Although the synthesis temperature is low, the reaction time is up to 24 hours, which has some limitations in terms of time and cost.

(2) Additive-assisted synthesis at low temperature

At a particular reaction temperature, different additives, such as tartaric acid Na, polyacrylamide, manganese chloride, uniformly dissolved in deionized water being solicited, in the case of soliciting, at the same time, magnesium chloride solution and sodium carbonate solution added dropwise to the reactor, continuous stirring for a specific time, then stop, and leave it to stand for 4 days, that is, to obtain the spherical magnesium alkali carbonate.

(3) Direct synthesis by co-precipitation method

Adopt soluble magnesium salt as well as soluble carbonate as experimental raw materials, adjust the pH value in the aqueous system by hydrochloric acid or ammonia, and utilize the hydrothermal synthesis reaction to prepare nearly spherical bird’s-nest shaped magnesium carbonate in base form.

2. Indirect synthesis method

Indirect synthesis method is first synthesized other forms of magnesium carbonate, after pyrolysis to produce spherical basic magnesium carbonate synthesis method.

(1)Method of adding sodium oxalate to heavy magnesium water

Lightly burned dolomitic ash powder as experimental raw materials, using the method of carbonization, before adding sodium oxalate to remove calcium, and then carry out the pyrolysis of heavy magnesium water, prepared to obtain high-purity magnesium oxide samples. Then pyrolysis, pyrolysis product alkaline magnesium carbonate, alkaline magnesium carbonate calcination will get the product of spherical magnesium oxide.

(2) Carbon dioxide conditioning method

Take magnesium sulfate heptahydrate and sodium carbonate as the reaction raw material, under the reaction temperature, the sodium carbonate solution in the magnesium sulfate solution stirring in the case of – a certain speed added to the reaction system. After the end, carbon dioxide gas is passed into the reaction system to adjust the crystal form of magnesium carbonate, and this process is carbonization process. It is then left to stand for some time, filtered and washed. The resulting product is subjected to pyrolysis reaction so that the product is completely converted to basic magnesium carbonate.

Write at the end

Magnesium oxide has good chemical inertness, heat resistance, insulation and thermal conductivity and other properties, for specific application background and application occasions, regulate the shape and surface properties of magnesium oxide, control its physical shape, surface area, pore size and pore volume, the chemical properties of magnesium oxide and its shape and surface properties of the organic combination of magnesium oxide will be special shape of magnesium oxide will provide a broader space for the application of the special shape of magnesium oxide.

Now the preparation process of spherical magnesium oxide is not too mature, and its excellent performance has not been recognized by most people, so the development of the preparation process of spherical magnesium oxide and a wider range of applications has a good market prospect.