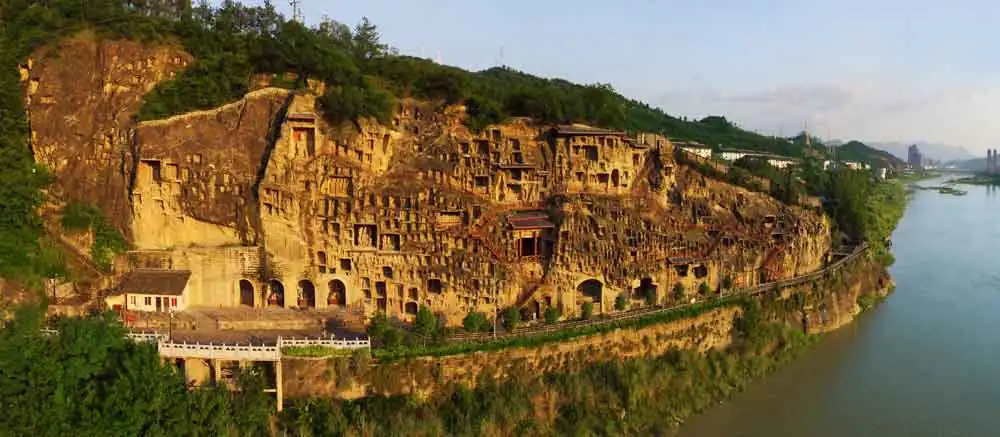

Thousand Buddha Cliff is located in Guangyuan City, Sichuan Province. The grottoes on the cliff were carved in the late Northern Wei Dynasty, flourished in the Tang Dynasty and ended in the Qing Dynasty. It is nearly 388 meters long and 45 meters high, forming a grotto corridor composed of more than 950 Buddhist niches and more than 7,000 Buddha statues, so it is called the “Thousand Buddha Cliff”. It is the largest Buddhist grotto in Sichuan Province and is magnificent. On the one hand, Guangyuan is located in the subtropical humid monsoon climate zone with heavy annual rainfall. On the other hand, the repeated dissolution-crystallization of soluble salts on the sandstone surface is another important reason. Curing treatment is necessary to restore intergranular cohesion. Inorganic reinforcing agents are the first choice for repairing weathered sandstone.

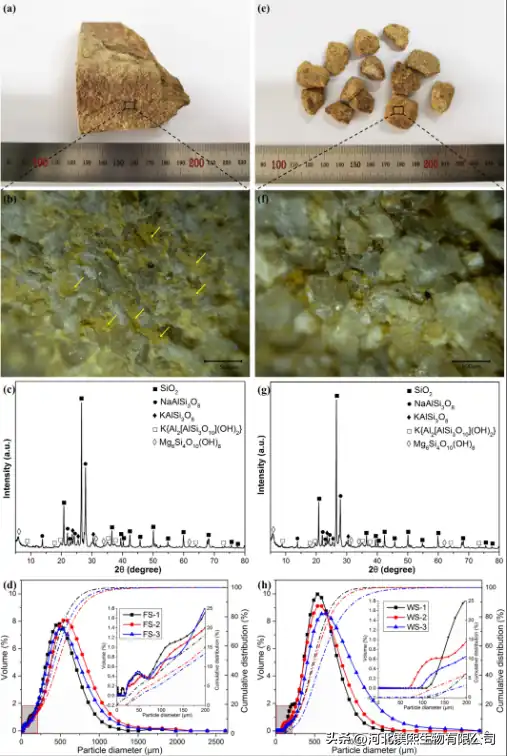

Magnesium oxychloride cement (MOC) is an air-hardening cement. This cement material is made of MgO, MgCl2 and H2O mixed in a specific molar ratio, and solidifies based on the reaction of water at room temperature. It has high mechanical strength, good thermal stability and excellent bonding ability. However, the process of using MOC mortar encountered some difficulties. First, due to its high viscosity, MOC mortar has difficulty penetrating into sandstone pores. Ethanol disperses magnesium oxide particles, reduces agglomeration, and increases penetration depth. Secondly, when ordinary magnesium oxide is used as raw material to prepare the curing agent, the magnesium oxide particles may block the pores of the sandstone. Compared with ordinary magnesium oxide, nanomagnesium oxide has smaller particle size, higher specific surface area and stronger activity.

This article studies the feasibility of using ethanol as a dispersant and using nano-magnesium oxide instead of ordinary magnesium oxide to consolidate weathered sandstone samples, and explores the best treatment method (i.e., the concentration of the curing agent and the number of uses) , and initially evaluate the consolidation performance. The preparation process of the curing agent (MMH dispersion) is as follows: Mix nano-magnesium oxide, MgCl2·6H2O and H2O in a glass beaker, according to n(MgO):n(MgCl2·6H2O):n(H2O)=5:1: Prepare MMH mortar with a mole of 16. Next, it is dispersed with ethanol and sonicated. The application method is as follows: Use a disposable dropper to add the MMH dispersion from the upper surface of the AWSS at a rate of 40 drops/minute. After treatment, the samples were kept at a temperature of 25°C and a relative humidity of 60% for 7 days. All specimens were weighed before and after the consolidation treatment to record the absorbed solid phase.

Viscosity and XRD analysis showed that ethanol is a viable solvent and does not inhibit the formation of solidification products. The formed 5Mg(OH)2·MgCl2·8H2O generates strong adhesion between sand grains, which is the main source of mechanical strength. SEM-EDS characterization shows that consolidation treatment can improve the compactness of weathered specimens and ultimately form a coherent structure. In addition, the consolidation performance is greatly affected by the concentration of the curing agent and the number of applications. As the amount of cement penetrating into the specimen increases, the cured specimen shows significant improvement in mechanical strength and resistance to salt crystallization, and the water absorption decreases as the consolidation product partially fills the voids of the sand grains. . However, excessive accumulation of cement can lead to significant color changes on the specimen surface and therefore pose a risk of incompatibility. The results of this study indicate that in order to achieve optimal consolidation properties, an intermediate concentration of MMH dispersion (30 wt.%) should be selected and five replicates of weathered specimens should be processed.