On March 3, 2022, Shen Hai of Sichuan Orthopaedic Hospital, Antoniac Vasile Iulian of the Institute of Materials Science and Engineering, Bucharest University of Technology, and Xiangdong Zhu of the National Research Center for Biomaterials Engineering and Technology, Sichuan University, and their team jointly published a paper entitled “Construction of a magnesium hydroxide/graphene oxide/hydroxyapatite composite coating on Mg-Ca-Zn” in Bioactive Materials. “Construction of a magnesium hydroxide/graphene oxide/hydroxyapatite composite coating on Mg-Ca-Zn Ag alloy to inhibit bacterial infection and promote bone regeneration”, providing a promising surface modification strategy for multifunctional magnesium-based implants with good corrosion resistance, antimicrobial ability and osteogenic activity. strategy.

In this article, the CloudClone kit [Pre-collagen Type I Amino-terminal Progenitor Peptide (PINP) Detection Kit (ELISA), SEA957Ra] was recognized by researchers and was listed in the Outstanding International Journals.

Research Brief

Magnesium (Mg) and its alloys, as a new generation of medical metallic materials, have attracted much attention due to their biodegradability and closed modulus of elasticity to natural cortical bone. Compared with traditional permanent metallic implants such as stainless steel, titanium and titanium alloys, magnesium-based implants can avoid the disadvantages of secondary surgery and stress shielding. More importantly, magnesium ions can promote bone regeneration and accelerate fracture healing by modulating bone biomineralization and contributing to the formation of a bone immune microenvironment. However, the rapid degradation of magnesium-based implants under physiological conditions generates large amounts of hydrogen, leading to an exponential decrease in the mechanical strength of the implant, impaired bone healing, and internal fixation failure. In addition, during tissue repair, bacteria may adhere and colonize on the implant surface, rapidly proliferate and eventually form a dense bacterial film, which greatly inhibits the killing effect of antibiotics and hinders subsequent osteogenesis, leading to implant failure. Therefore, the development of multifunctional magnesium-based implants with good corrosion resistance, antimicrobial capacity, and osteogenic activity is highly desirable to meet complex clinical needs.

Studies have shown that in situ preparation of Mg(OH)2 nanosheet coatings on pure Mg surfaces by alkali heat treatment significantly enhances the corrosion resistance and antimicrobial capacity of the matrix material; calcium phosphate (CaP)-based coatings, which are chemically similar to the inorganic constituents of natural bone tissues, are the most commonly used and researched bioactive coatings to enhance the corrosion resistance of magnesium alloys; and graphene oxide (GO) is the most commonly used and researched coating for enhancing the corrosion resistance of magnesium alloys due to its unique two-dimensional network structure, abundant chemical functional groups and large specific surface area, it is considered as an ideal nanoscale filler for surface coating enhancement. Therefore, the combination of Mg(OH)2, CaP, and GO may be a suitable approach for constructing functional composite coatings on magnesium alloy surfaces with excellent corrosion resistance, osteogenic activity, and antimicrobial capacity.

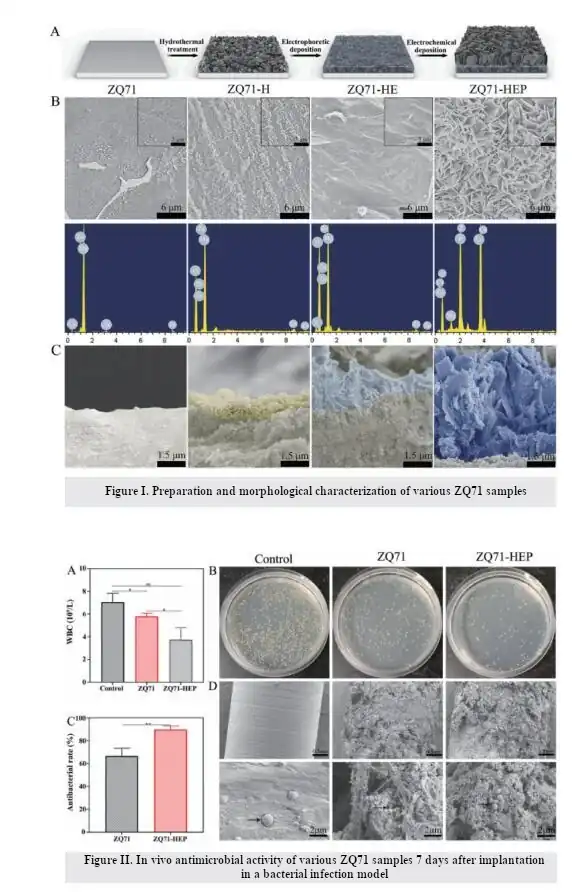

First, the Mg-0.8Ca-5Zn-1.5Ag (ZQ71) alloy with the best performance was selected as the target material based on the authors’ previous studies, and the Mg(OH)2 coating (named ZQ71-H) was prepared in situ on its surface by hydrothermal treatment using sodium hydroxide solution. Next, electrophoretic deposition was applied to generate a GO layer (named ZQ71-HE) on the ZQ71-H surface. Finally, a hydroxyapatite (HA) composite coating (named ZQ71-HEP) was constructed on the ZQ71-HE surface by electrochemical deposition. The composite coating with high bond strength and nanoscale morphology significantly enhanced the corrosion resistance of ZQ71 alloy and reduced the degradation rate. In vitro cell culture using MC3T3-E1 cells showed that the composite coating-modified ZQ71 alloy (ZQ71-HEP) had higher cell viability and gene expression levels of osteogenesis-related genes than ZQ71. In addition, enhanced antibacterial activity against Gram-positive (Staphylococcus aureus) and Gram-negative (Escherichia coli) bacteria was observed on ZQ71-HEP. After in vivo implantation, ZQ71-HEP showed excellent bactericidal and bone-enhancing effects in both normal and infected environments compared to the ZQ71 group and the control group.

In summary

The authors’ study provides a promising surface modification strategy for the development of multifunctional magnesium-based implants with good corrosion resistance, antimicrobial capacity and osteogenic activity, and expands the biomedical applications of magnesium-based materials.