Magnesium hydroxide [Mg(OH)2] is a kind of flame retardant that we are all familiar with, and is often added to polymer materials to improve the safety coefficient of polymer materials with flammability and high smoke generation. When encountering fire, magnesium hydroxide will decompose and release bound water after being heated to absorb a large amount of latent heat, reducing the surface temperature of the filled synthetic material in the flame; at the same time, it can also inhibit smoke, greatly reducing the smoke density during combustion, reducing the risk of suffocation of people trapped in the fire due to dense smoke.

Such an excellent flame retardant, do their own job is very good. However, sometimes it can also be overplayed – for example, recently a researcher found that, under certain conditions, magnesium hydroxide and other thermally conductive filler together with the polymer material, but also can play a “synergistic thermal conductivity” role at the same time.

Why study the role of thermal conductivity of magnesium hydroxide?

At present, high thermal conductivity insulating materials in aerospace and electrical equipment and other fields have a wide range of applications, in terms of electrical equipment, with the rapid growth of power demand, power transmission equipment such as transformers, insulated cables, the capacity of more and more large, resulting in more and more high heat, the insulation material is therefore accelerated aging, resulting in the service life of the equipment to be reduced, so improve the thermal conductivity of the insulating material in the power cable, the enhancement of the core of the cable has an important practical significance. Flow has important practical significance.

For cable materials, insulation is important, thermal conductivity is also important!

Currently at home and abroad to enhance the thermal conductivity of composite materials is mainly in the polymer matrix through a certain blending method doped thermal conductivity of higher thermal conductivity filler. Thermally conductive filler variety, the current single filler thermal conductivity insulation composites research has been more perfect, the prominent filler representative of alumina (Al2O3), aluminum nitride (AlN), boron nitride (BN) and so on.

Among them, AlN has a very high thermal conductivity, but it is expensive. In order to obtain better thermal conductivity, the application of manufacturers will often take the form of “mix and match” to the polymer material to add two or more kinds of thermally conductive filler. For the power cable insulation materials mentioned above, the second filler selection needs to consider the cable just need – power cable insulation materials commonly used in the limit of oxygen index (LOI) most of the following 21%, which means that these materials in the air is very easy to burn, and add a large number of insulating materials in the flame retardant materials can improve the composite materials The addition of a large amount of flame retardant to the insulating material can increase the oxygen index of the composite material, which can realize rapid heat absorption and smoke elimination when the material burns, and improve its reliability and safety, so the flame retardant can be used as the second filler, which is the magnesium hydroxide [Mg(OH)2] used in this study.

Effect of incorporation of magnesium hydroxide

According to the study, the doping of Mg(OH)2 brings the following main effects:

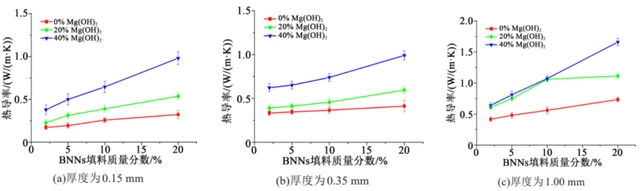

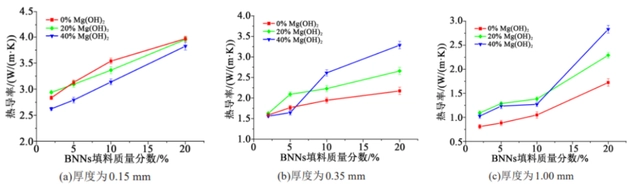

(1) In the multifiller composites, the doping of Mg(OH)2 can improve the thermal conductivity of the composites and produce a certain degree of synergistic effect with the BNNs in terms of axial thermal conductivity, which further improves the axial thermal conductivity of the composites.

(2) At different doping contents, the thickness greatly affects the thermal conductivity of the materials, and the composites at thin thicknesses are more likely to induce the BNNs to align along the radial direction of the specimen compared to the composites at thicker thicknesses, which macroscopically improves the radial thermal conductivity of the composites, and the composites show a stronger anisotropy in the thermal conductivity.

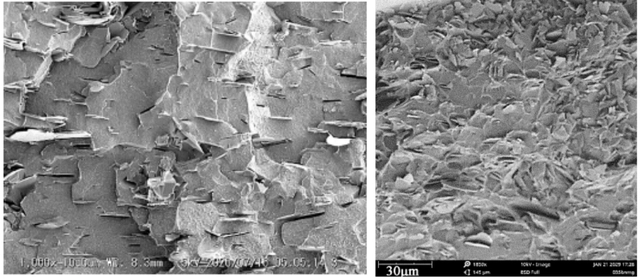

(3) At a certain thickness, when the Mg(OH)2 filler content is similar to the BNNs filler content, Mg(OH)2 further enhances the radial alignment of the BNNs and thus improves the radial thermal conductivity of the composites, and when the Mg(OH)2 filler content is much higher than that of the BNNs filler content, Mg(OH)2 inhibits the radial alignment of BNNs and thus reduces the radial thermal conductivity of the composite. At the same time, the incorporation of Mg(OH)2 with high filler content also prevents the BNNs from forming large thermal conductivity pathways, which also reduces the radial thermal conductivity of the composites.

Left: cross-section morphology of single-filler composites, which shows the high radial alignment of BNNs;

Right: cross-section topography of the multifiller composite, a large amount of Mg(OH)2 doping will block the interconnection of BNNs.

(4) The doping of both Mg(OH)2 and BNNs increases the dielectric constant and dielectric loss factor of the composites at industrial frequency, and the dielectric properties increase with the increase of the content of the two fillers, resulting in the decrease of the dielectric properties of the composites, but the decrease of the dielectric properties of the composites is small compared with the increase of the thermal conductivity.

Summarize

These are the reasons why magnesium hydroxide can be synergistically thermally conductive in cable insulation materials. Although the relevant research is still at an early stage, it also proves that similar “atypical thermal conductive materials” may play an unexpected role as long as they appear in the right posture on the right occasion.