Magnesium carbonate is widely used in building materials, cosmetics, medicine, food additives and refractory materials as fillers, desiccants or buffers. The production process of magnesium carbonate has been maturing in recent years, and the future production process is developing towards a green and environmentally friendly trend. The following is an analysis of the current status of the magnesium carbonate industry in 2024.

Status of the magnesium carbonate industry

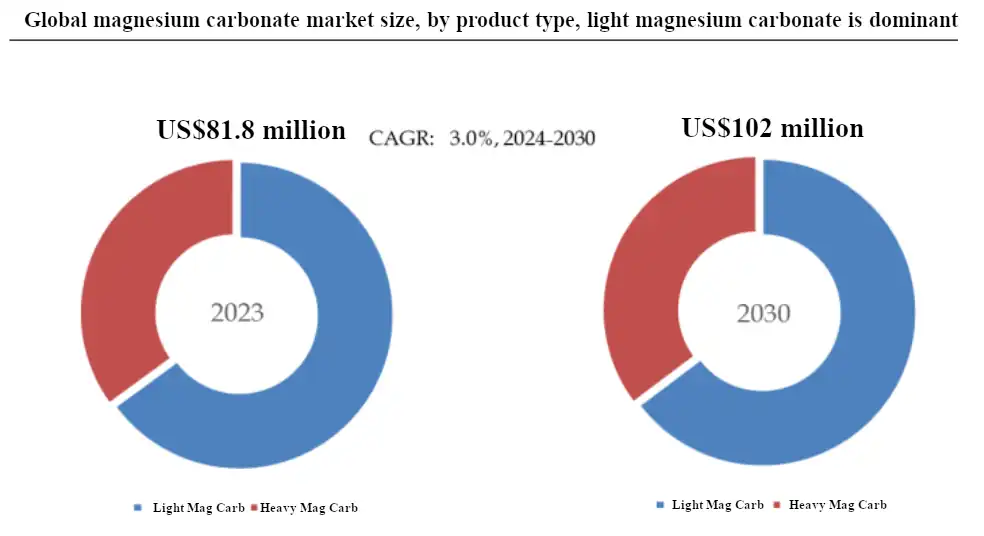

The specific values of the global magnesium carbonate market size vary. The “2024-2029 China Magnesium Carbonate Industry Development Trend Analysis and Future Investment Research Report” pointed out that the global magnesium carbonate market size will reach RMB 1.171 billion (or US$81.8 million) in 2023, and it is predicted that it will grow at an average annual compound growth rate of 3.0% to 3.64% in the next few years, reaching RMB 1.443 billion (or US$110 million, US$102 million) by 2029 or 2030 respectively.

China is one of the important producers and consumers of magnesium carbonate in the world. According to the current status analysis data of the magnesium carbonate industry, the scale of China’s magnesium carbonate market will reach RMB 680 million in 2023, and it will show a trend of sustained growth. The development of China’s magnesium carbonate market is closely related to the rapid development of downstream industries, especially the sustained growth of rubber, plastics, pharmaceuticals and other industries, which provides strong demand support for the magnesium carbonate market.

Global magnesium carbonate producers mainly include Konoshima Chemical, Dr. Paul Lohmann, Naikai Salt Industries, Liaoning Xinghai Pharmaceutical, Zehui Chemical, Messi Biology, Meishen, Yixing Lark Fine Chemical, Hebei Gaolin, Yingkou Magnesite Chemical, etc. In 2023, the top ten manufacturers in the world accounted for about 61.0% of the market share. In terms of product type, light magnesium carbonate is currently the most important subdivided product, accounting for about 66.4% of the share.

Magnesium carbonate industry production process

The production process of magnesium carbonate mainly includes precipitation method, hydrolysis method and pyrolysis method. Precipitation method This is one of the main methods for producing magnesium carbonate. The principle is to add a precipitant (such as sodium carbonate, sodium bicarbonate, etc.) to a solution containing magnesium ions to react with magnesium ions to form a magnesium carbonate precipitate, and then filter, wash, dry and other processes to obtain the finished product. This method has the advantages of simple operation and low cost, but the product quality may be affected by factors such as raw material purity and reaction conditions. The hydrolysis method is to react magnesium metal with water to generate magnesium hydroxide, and then react it with carbon dioxide to generate magnesium carbonate. This method can better control the purity and particle size distribution of the product, but the production cost is relatively high, and the equipment and technical requirements are also high.

In recent years, with the continuous development of science and technology, the magnesium carbonate industry has made significant progress in production technology. Many companies have adopted advanced production equipment and technical means to improve the purity and quality stability of products. At the same time, some companies are also committed to developing new production processes and formulas to meet the special needs of magnesium carbonate in different fields. In order to improve production efficiency and product quality, some magnesium carbonate companies have realized the automation and intelligence of the production process. By introducing advanced automatic control systems and intelligent detection equipment, companies can monitor various parameters in the production process in real time to ensure the stability and consistency of product quality.

Analysis of the current situation of the magnesium carbonate industry shows that with the improvement of environmental awareness and the strengthening of environmental protection regulations, the magnesium carbonate industry has also paid more and more attention to environmental protection and energy saving in production technology. Many companies use low-energy consumption and low-pollution production processes and equipment to reduce the impact on the environment. At the same time, some companies have also achieved green production by recycling resources and reducing waste emissions.

Overall, the magnesium carbonate industry continues to develop in the direction of high efficiency, environmental protection and intelligence in production technology. In the future, with the continuous advancement of technology and the continuous expansion of the market, the magnesium carbonate industry is expected to usher in a broader development prospect.