Properties

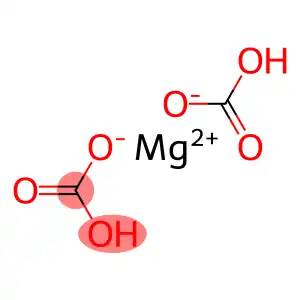

This product is hydrated basic magnesium carbonate, with a magnesium oxide content of 40.0% to 43.5%. It is a white powder, non-toxic, odorless, and almost tasteless. It is stable in the air and almost insoluble in water or ethanol, but can make water weakly alkaline. It releases carbon dioxide and dissolves in dilute acid. It decomposes above 300°C, releasing water and carbon dioxide to generate magnesium oxide.

Preparation method

Brine-soda method: First pre-treat bittern and sodium carbonate solution and then perform precipitation reaction, filter, wash, dehydrate, dry, and crush to produce medicinal magnesium carbonate.

Magnesium double decomposition method: Use ammonium sulfate solution and magnesia to perform double decomposition reaction to generate magnesium sulfate solution, and then use the recovered ammonia to prepare carbonized ammonia water, and precipitate basic magnesium carbonate with magnesium sulfate solution, and then filter, wash, dehydrate, dry, and crush to produce medicinal magnesium carbonate.

Use

Mainly used in the pharmaceutical industry, for the treatment of gastric and duodenal ulcers and other diseases.

Safety

Pack in double layers with polyethylene plastic bag as inner lining and plastic woven bag as outer covering, or in single layer with plastic bag covered with film.

Magnesium bicarbonate – Check

Color of acidic solution

Take 1.0g of this product, add 20ml of glacial acetic acid solution (6-50), ultrasonically dissolve it, filter it if necessary, the solution should be colorless; if it is colored, compare it with the yellow-green No. 2 standard colorimetric solution (General Rule 0901 Method 1), it should not be darker.

Chloride

Take 5.0g of this product, add 20ml of water and 30ml of acetic acid to dissolve, boil for 2 minutes, cool, filter, wash the residue with dilute acetic acid, combine the washing liquid and the filtrate, dilute it with dilute acetic acid to 50ml, shake well, and use it as the test solution. Accurately measure 2ml, add water to make 25ml, check according to the law (General Rule 0801), and compare it with the control solution made of 7.0ml of standard sodium chloride solution, it should not be more concentrated (0.035%).

Sulfate

Accurately measure 1 ml of the test solution under the chloride item, dilute it with water to 25 ml, take 10 ml of the solution, check it according to the law (General Rule 0802), and compare it with the control solution made of 2.0 ml of standard potassium sulfate solution. It must not be more concentrated (0.5%).

Calcium oxide

Accurately measure 5 ml of the test solution under the chloride item, add 300 ml of water, then add 10 ml of triethanolamine solution (3-10) and 10 ml of 45% potassium hydroxide solution, let it stand for 5 minutes, add 0.1 g of calcium purpurogenous pigment indicator, and titrate it with disodium ethylenediaminetetraacetic acid titration solution (0.01 mol/L) until the solution changes from purple-red to blue, and correct the titration result with a blank test. Each 1 ml of disodium ethylenediaminetetraacetic acid titration solution (0.01 mol/L) is equivalent to 0.5608 mg of CaO. The calcium oxide content of this product shall not exceed 0.60%.

Soluble salts

Take 1.0g of this product, add 50ml of water, boil for 5 minutes, filter, evaporate the filtrate on a water bath, and dry at 105°C for 1 hour. The residue shall not exceed 10mg (1.0%).

Insoluble matter in acid

Take 5g of this product, add 75ml of water, and then add a small amount of hydrochloric acid in batches, stirring as it is added until it no longer dissolves, boil for 5 minutes, filter, wash the filter residue with water until the washing liquid no longer shows chloride reaction, ignite to constant weight, and the residue shall not exceed 2.5mg (0.05%).

Iron salt

Take 0.25g of this product, add 5ml of dilute nitric acid, boil for 1 minute, cool, dilute with water to 35ml, check according to the law (General Rule 0807), and compare with the control solution made of 5.0ml of standard iron solution, it shall not be darker (0.02%).

Mercury

Take two portions of about 1g of this product, weigh them accurately, and place them in 50ml volumetric bottles respectively. Add 30ml of 8% hydrochloric acid and 0.5ml of 5% potassium permanganate solution to one portion, shake well, add 5% hydroxylamine hydrochloride solution until the purple color disappears, dilute to the mark with 8% hydrochloric acid solution, shake well, and use it as the test solution; accurately add 5ml of standard mercury solution [accurately measure an appropriate amount of mercury single element standard solution, dilute with water to make a solution containing 0.lug of mercury (Hg) per 1ml] to the other portion, operate in the same way, and use it as the reference solution. According to the atomic absorption spectrophotometry method (General Rule 0406 Second Method), the measurement at a wavelength of 253.6nm should meet the requirements (0.00005%).

Heavy metals

Precisely measure 5 ml of the test solution under the chloride item, add 1 drop of phenolphthalein indicator and an appropriate amount of ammonia test solution until the solution turns light red, add 2 ml of acetate buffer (pH 3.5) and an appropriate amount of water to make 25 ml, add 0.5 g of ascorbic acid, dissolve, check according to the law (General Rule 0821 Method 1), leave for 5 minutes for colorimetry, and the heavy metal content shall not exceed 30 parts per million.

Arsenic salts

Precisely measure 10 ml of the test solution under the chloride item, add 5 ml of hydrochloric acid, add water to make 28 ml, check according to the law (General Rule 0822 Method 1), and it should meet the requirements (0.0002%).