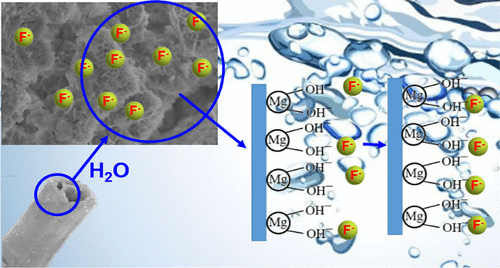

The essence of the reaction mechanism for fluoride removal using magnesium oxide is the “slow dissolution of Mg²⁺, combining with F⁻ to form MgF₂ precipitate, accompanied by a certain degree of surface adsorption.”

1. Basic Reaction Equations

In aqueous solution, magnesium oxide (MgO) reacts with fluoride ions (F⁻) to form magnesium fluoride (MgF₂) precipitate:

MgO + 2HF → MgF₂↓ + H₂O

or simplified in aqueous solution as:

Mg²⁺ + 2F⁻ → MgF₂↓

Magnesium oxide hydrolyzes in water to form magnesium hydroxide, which further releases Mg²⁺, reacting with F⁻ to form a precipitate:

MgO + H₂O → Mg(OH)₂ → Mg²⁺ + 2OH⁻

2. Analysis of Reaction Process Mechanism

① Magnesium Oxide Hydrolysis and Mg²⁺ Release:

Magnesium oxide itself is a basic oxide, insoluble in water but capable of partial hydrolysis, slowly releasing Mg²⁺ ions. This “slow-release” characteristic makes the reaction relatively mild and controllable.

② Fluoride Ion Binding with Mg²⁺:

F⁻ possesses strong nucleophilicity and readily combines with Mg²⁺ to form magnesium fluoride, which has very low solubility and precipitates quickly, thus reducing the fluoride concentration in the water.

③ Coexistence of Adsorption and Precipitation:

Some fluoride ions may initially be adsorbed onto the surface of magnesium oxide or magnesium hydroxide before being converted into magnesium fluoride precipitate. This indicates that the process involves:

- Surface adsorption (physical/chemical adsorption)

- Ionic reaction in solution (precipitation)

3. Key Factors Influencing Mechanism Performance

- pH Value: Magnesium oxide exhibits the strongest reactivity in neutral to weakly alkaline conditions; the reaction is limited at excessively high pH.

- Temperature: Increasing the temperature can accelerate both the hydrolysis and precipitation processes, but it should not be too high to avoid affecting the material’s structure.

- Fluoride Concentration: At high fluoride concentrations, magnesium fluoride forms rapidly, leading to a faster fluoride removal rate; at low concentrations, the process becomes more reliant on adsorption.

- Stirring Speed: Affects the degree of contact between the particle surface and ions in the solution.

- Magnesium Oxide Crystal Form and Specific Surface Area: Nano-sized magnesium oxide or porous structured materials are more conducive to improving the reaction rate and adsorption capacity.

4. Research Methods for Mechanism Study

- XRD (X-ray Diffraction): Detects the crystal structures of magnesium oxide and the formed magnesium fluoride.

- FTIR (Fourier Transform Infrared Spectroscopy): Analyzes changes in surface functional groups.

- SEM/TEM (Scanning Electron Microscopy/Transmission Electron Microscopy): Observes the surface morphology of particles and the structure of the precipitate.

- ICP-MS (Inductively Coupled Plasma Mass Spectrometry): Monitors the concentration changes of F⁻ and Mg²⁺ in the solution.

- Adsorption Isotherm Fitting: Helps understand whether physical adsorption or chemical reaction is the dominant mechanism.