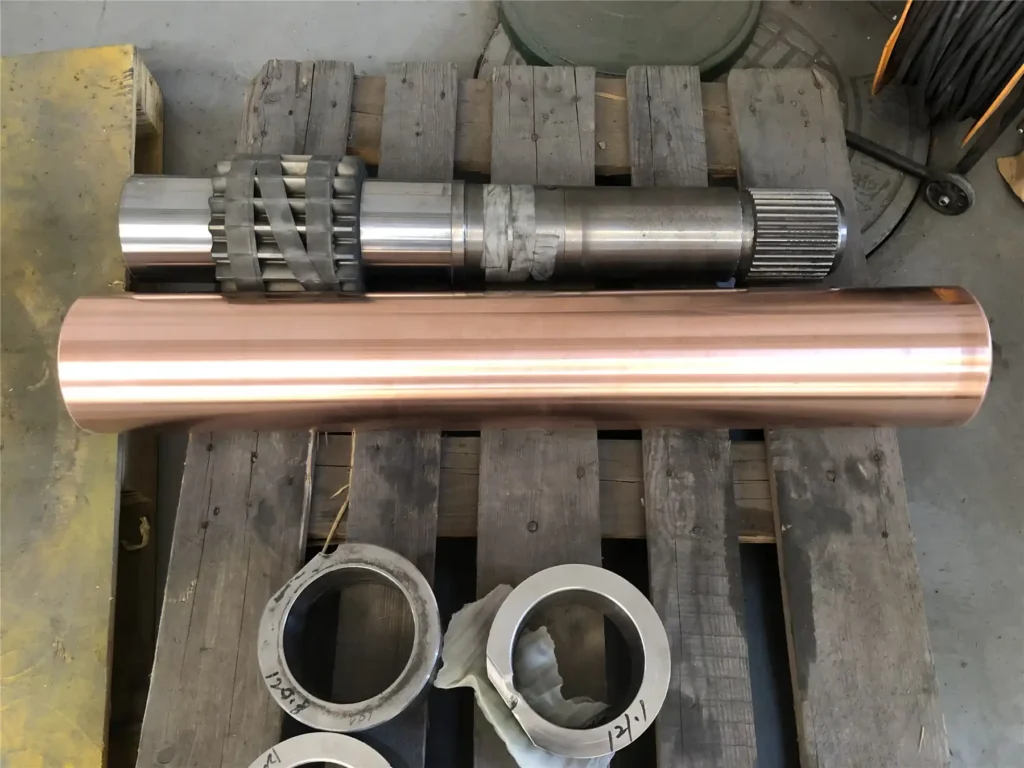

Abrasive copper roller surfaces, due to prolonged exposure to ink, resin, and oxides, are prone to stubborn stains and micro-scratches. Traditional strong acid cleaning easily corrodes the surface texture. Magnesium Carbonate (MgCO₃), as an environmentally friendly inorganic abrasive and pH regulator, has become an ideal component in high-end cleaning formulations.

Core Functions of Magnesium Carbonate

1. Fine Grinding for Decontamination

Magnesium carbonate microparticles (typically with a particle size of 5–20μm) are evenly dispersed in the cleaning solution. Through gentle friction, they effectively peel off oxide layers, carbon deposits, and organic residues from the copper roller surface, while protecting the abrasive texture from damage. Compared to hard abrasives like silica sand, its Mohs hardness is only 3–4, avoiding secondary scratches on the copper roller surface (hardness ≈ 3).

2. Alkaline Buffering and Regulation

Upon dissolution, it forms a weakly alkaline environment (pH 8.5–9.5), neutralizing acidic pollutants, breaking down grease, and inhibiting copper ion oxidation, maintaining the metal’s original color on the roller surface. Synergistic enhancement with surfactants improves emulsification and degreasing efficiency by over 30%.

3. Anti-Settling and Rheology Optimization

Nano-scale magnesium carbonate improves the suspension stability of the cleaner, preventing the deposition of solid components and ensuring the cleaning solution acts uniformly on the roller surface.

Application Effects

- Improved Cleanliness: Stain removal rate ≥ 95%, restoring the matte and uniform texture of the copper roller.

- Equipment Protection: Copper roller wear rate reduced to < 0.1μm/cleaning cycle.

- Environmental Friendliness: Good biodegradability, no heavy metal residue, reducing wastewater treatment costs by 40%.

This solution has been applied in high-end printing machinery and copper plate rolling production lines, achieving a three-in-one objective of high-efficiency cleaning – zero damage – long-term protection for abrasive copper rollers. In practical applications, parameters should be fine-tuned based on the severity of the soiling. It is recommended to perform a small-area test before the first use.