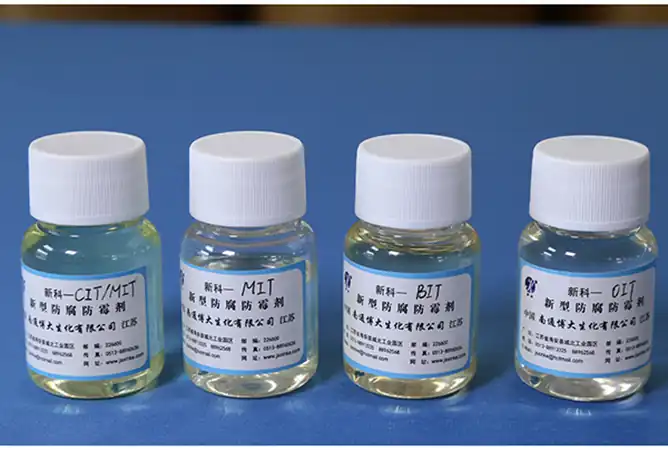

Isothiazolinone preservatives (such as CMIT, MIT, BIT, etc.) are widely used in chemical, daily chemical, coatings, water treatment, and other fields. They are highly favored for their broad-spectrum bactericidal activity, low dosage, and high cost-effectiveness. However, this type of preservative is quite sensitive to the pH value of the application environment. Under acidic or alkaline conditions, they are prone to hydrolysis, oxidation, or structural breakdown, leading to inactivation or the generation of by-products.

I. Influence of pH on Isothiazolinone Stability

Isothiazolinone substances typically have good stability in the pH range of 4 to 8;

When the system pH is too low (<4), it leads to an accelerated hydrolysis rate and a reduction in the active ingredient;

When the system pH is too high (>8), ring-opening or degradation reactions are likely to occur;

Unstable pH can also easily accelerate side reactions between other components in the formulation and isothiazolinones, affecting the overall preservative effect.

II. Magnesium Oxide’s Regulation Mechanism

Magnesium oxide (MgO) is a weakly alkaline inorganic oxide. Its pH regulation is mainly achieved through the following two mechanisms:

- Acid Neutralization Reaction

Magnesium oxide reacts slowly in water to produce magnesium hydroxide, which gradually neutralizes free acids, causing the formulation pH to slowly transition towards neutral or slightly alkaline, with strong controllability.

MgO + H₂O → Mg(OH)₂ - Buffering Effect

Magnesium oxide has a certain buffering capacity, which can maintain the system pH within a narrow fluctuation range, inhibiting the impact of external pH disturbances on isothiazolinones.

III. Advantages of Use

- Good Controllability: The adjustment process is gentle and less likely to cause side reactions;

- High Safety: Non-toxic and odorless, does not affect the product’s scent and appearance;

- Synergistic Stabilization: Helps the stability of other preservatives (such as phenoxyethanol, sorbic acid);

- Reduced Reliance on Acid/Alkaline Additives: Can replace some organic bases like triethanolamine, improving the formulation’s green and environmental profile.

IV. Application Recommendations

- It is recommended to add a certain proportion of high-purity magnesium oxide powder (e.g., <10μm particle size) during the formulation stage to achieve pH buffering;

- Can be used in combination with phosphate buffer systems or organic amine pH adjusters to improve precision;

- Small-scale evaluation should be conducted based on the end formulation type (such as coatings, adhesives, water treatment agents, etc.) to optimize dosage and addition order.