Messi Biology states that magnesium oxide plays an irreplaceable role in microwave absorbing materials. Its excellent electromagnetic wave absorption capability, good impedance matching characteristics, stable physical and chemical properties, and enhancing effect on composite materials make magnesium oxide a key component in the preparation of high-performance microwave absorbing materials. With continuous technological advancements and expanding application areas, the core role of magnesium oxide in microwave absorbing materials will be further realized and utilized.

I. Excellent Electromagnetic Wave Absorption Capability

Magnesium oxide has a special crystal structure and electron arrangement that allows it to strongly interact with electromagnetic waves, effectively absorbing and converting their energy. This capability is particularly important in fields such as communications, radar, and aerospace, as it can significantly reduce electromagnetic wave interference with equipment and ensure the stability and security of signal transmission.

II. Good Impedance Matching Characteristics

Impedance matching refers to matching the surface impedance of the absorbing material to the impedance of free space, thereby reducing the reflection and scattering of electromagnetic waves. By adjusting its dielectric constant, magnetic permeability, and other electromagnetic parameters, magnesium oxide can achieve good impedance matching with free space, allowing electromagnetic waves to enter the material smoothly and be effectively absorbed. This characteristic gives magnesium oxide a significant advantage in preparing high-performance microwave absorbing materials.

III. Stable Physical and Chemical Properties

Magnesium oxide can maintain the stability of its physical and chemical properties in harsh environments such as high temperature, high humidity, and corrosion, and is not easily decomposed or deteriorated. This characteristic gives magnesium oxide a significant advantage in preparing high-performance, long-life microwave absorbing materials.

IV. Enhancing Effect on Composite Materials

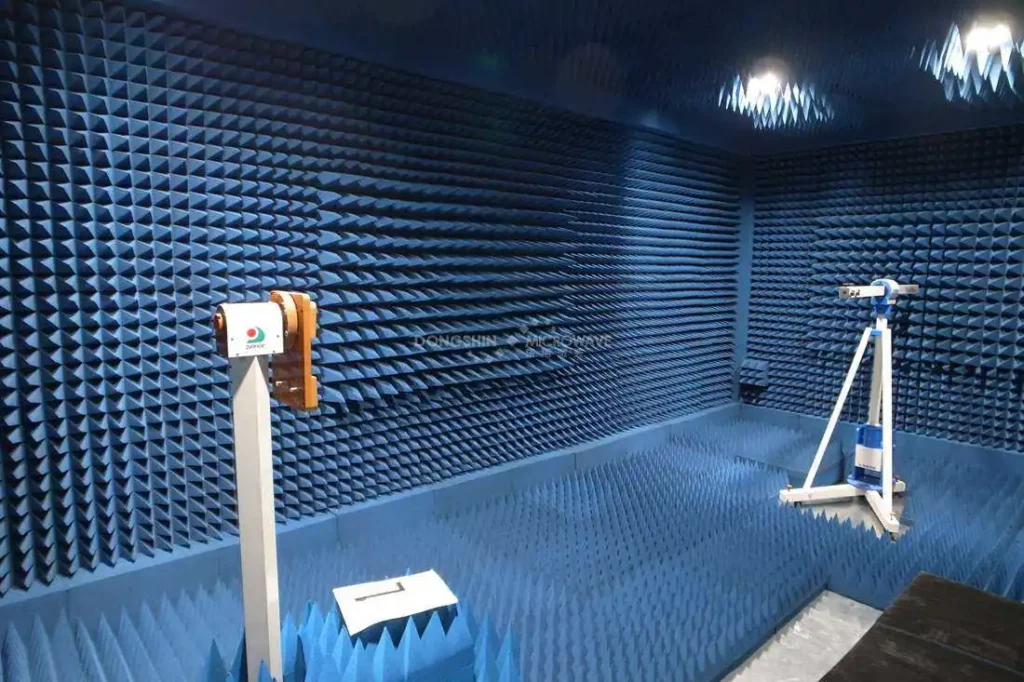

In practical applications, magnesium oxide is usually used in combination with other materials to form microwave absorbing composite materials with excellent comprehensive properties. For example, compounding nano-scale magnesium oxide with ferrites, carbon fibers, etc., can produce lightweight, high-strength, wide-band absorbing microwave absorbing coatings. Compounding magnesium oxide with polymer materials can produce microwave absorbing films with good flexibility and processing performance. These composite materials have broad application prospects in stealth technology, electromagnetic compatibility, and other fields.

V. Significant Advantages of Nano-Magnesium Oxide

Compared to micron-sized magnesium oxide, nano-magnesium oxide exhibits significant advantages in electromagnetic wave absorption. Nano-magnesium oxide has a larger specific surface area, providing more active sites, which enables it to more effectively absorb and convert incident electromagnetic wave energy. In addition, the electronic structure of nano-magnesium oxide changes at the nanoscale, exhibiting quantum effects, which makes its electromagnetic properties different from those of micron-sized magnesium oxide, thereby enhancing its absorption capacity for electromagnetic waves.