Messi Biology states that hexagonal magnesium hydroxide, due to its unique layered structure, high specific surface area, tunable surface chemical properties, and good thermal stability, has broad applications in the field of catalysis. It can serve not only as a catalyst itself but also as a catalyst support, enhancing the activity, stability, and selectivity of catalysts.

1. Role as a Catalyst

Hexagonal Mg(OH)₂ can be directly used as a catalyst, primarily owing to its alkaline surface, adsorption capacity, and catalytic active sites.

(1) Acid-Base Catalyzed Reactions

Mg(OH)₂ possesses strong alkalinity, enabling it to promote various base-catalyzed reactions, such as:

- Transesterification reactions: Used in biodiesel production, converting animal and vegetable fats/oils into fatty acid methyl esters.

- Alcoholysis reactions: Promoting the conversion of alcoholic compounds to synthesize organic intermediates.

- Knoevenagel reactions: A key reaction in organic synthesis for forming C=C bonds.

(2) Green Catalysis

Hexagonal Mg(OH)₂ can be used in solvent-free or aqueous phase catalysis, reducing the use of organic solvents and achieving green chemistry:

- Suitable for environmentally friendly organic synthesis, such as metal-free catalyzed aldol condensation reactions.

- In the field of CO₂ capture and catalytic conversion, it can be used for photocatalytic reduction of CO₂, converting CO₂ into valuable chemicals.

(3) Catalytic Dehydration Reactions

In organic synthesis, Mg(OH)₂ can act as a dehydrating agent, promoting the dehydration of alcohols or amines, such as the dehydration of cyclohexanol to cyclohexene.

At high temperatures, it decomposes to form MgO, which can be further used in hydrocarbon cracking and reforming reactions.

2. Role as a Catalyst Support

Due to its layered structure, high thermal stability, and good dispersibility, hexagonal Mg(OH)₂ can serve as a support for various catalysts, enhancing the dispersion and stability of active species.

(1) Supporting Metal Catalysts

Mg(OH)₂ possesses abundant surface hydroxyl groups, allowing it to support various metal nanoparticles (e.g., Pt, Pd, Ni, Cu) for catalytic hydrogenation, oxidation, reforming, and other reactions. For example:

- Nickel-supported magnesium hydroxide (Ni/Mg(OH)₂): Used for methane reforming to produce hydrogen, improving the dispersion of Ni particles and enhancing catalytic stability.

- Copper-supported magnesium hydroxide (Cu/Mg(OH)₂): Used for carbon monoxide oxidation, improving selectivity and anti-sintering performance.

(2) Supporting Oxide Catalysts

Mg(OH)₂ decomposes at 300–400°C to form magnesium oxide (MgO), which is a common catalyst or catalyst support and can be used for:

- Partial oxidation of methane to produce syngas (CO + H₂).

- Ethanol conversion to hydrogen, increasing hydrogen yield.

- Catalytic degradation of organic pollutants, such as photocatalytic degradation of dye wastewater.

(3) Supporting Photocatalytic Materials

- Mg(OH)₂/TiO₂ composite materials: Enhancing the photocatalytic performance of TiO₂ for the photodegradation of organic pollutants.

- Mg(OH)₂/g-C₃N₄ composite materials: Improving visible-light photocatalytic efficiency, applied in CO₂ reduction or water splitting for hydrogen production.

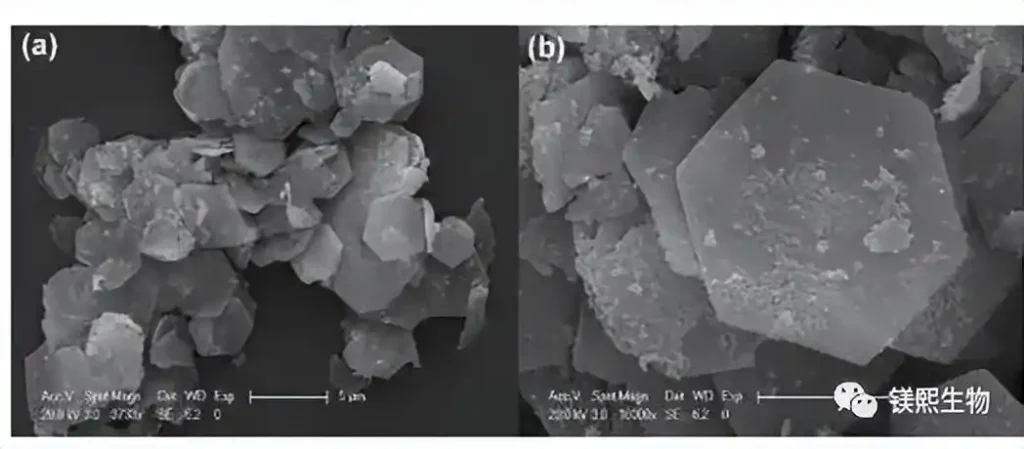

3. Influence of Morphology on Catalytic Performance

The morphology and specific surface area of hexagonal magnesium hydroxide significantly influence its catalytic performance.

(1) High Specific Surface Area

- Promotes the exposure of catalyst active sites, increasing reaction rates.

- Enhances adsorption capacity, making reactants more easily adsorbed onto catalytic sites.

(2) Layered Structure

- Favors improved dispersion of metal nanoparticles, preventing particle agglomeration.

- In certain catalytic reactions, it can enhance reactant selectivity, such as in ethanol dehydrogenation to produce hydrogen.

(3) Interlayer Spacing Control

- Through doping (e.g., with Al³⁺, Zn²⁺), the interlayer spacing can be regulated, enhancing ion exchange capacity and optimizing catalytic performance.

- Applicable to layered catalytic reactions, such as interlayer intercalation catalysis.