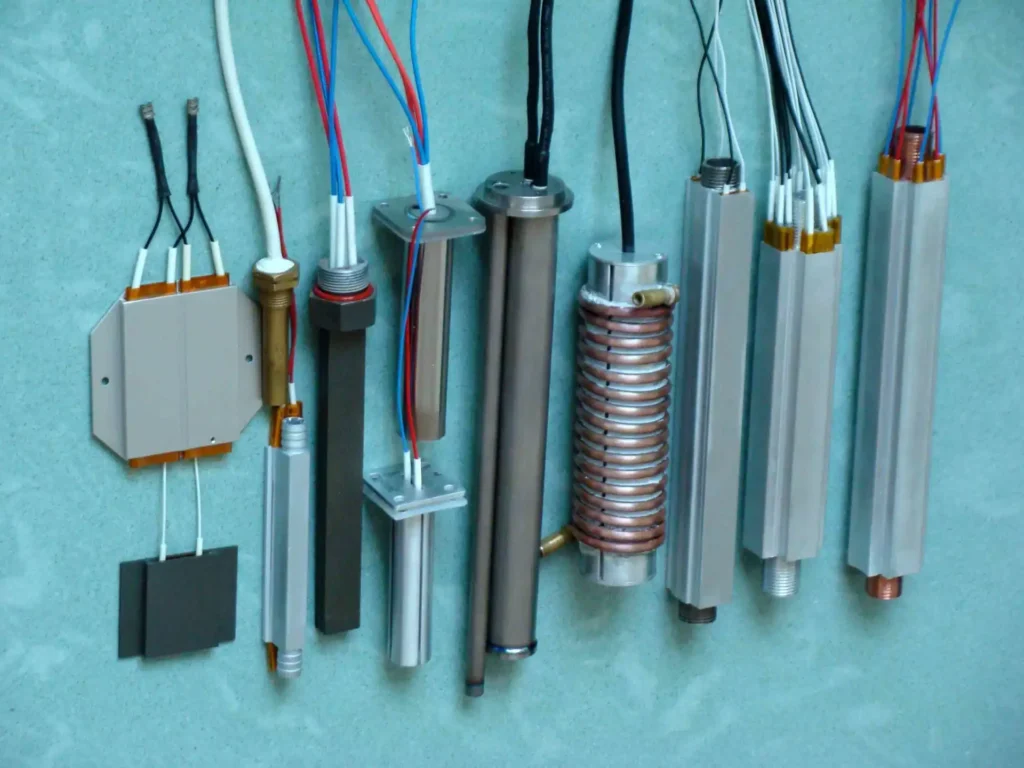

Hebei Messi Biology Co., Ltd. states that in winter, space heaters and air conditioner auxiliary heating bring us warmth. Many of the core heating elements in these devices come from a type of thermistor ceramic chip called “PTC” (Positive Temperature Coefficient). Behind this small component, magnesium oxide plays an indispensable role as an “insulating and thermally conductive guardian.”

The PTC ceramic chip itself has fascinating properties: low resistance when cold, quickly heats up when powered; when its temperature rises to a specific value (Curie point), its resistance dramatically increases, thereby automatically reducing power to achieve a constant temperature and warming effect, making it very safe and efficient. However, this delicate ceramic chip needs to be tightly integrated with metal electrodes and efficiently transfer heat to external heat sinks or the air, while absolutely ensuring electrical insulation to prevent the risk of leakage.

This is where magnesium oxide powder comes into play. It is tightly packed between the PTC chip and the aluminum heat dissipation casing, forming a “filler layer.” This layer plays three core roles:

- Electrical Insulation: Magnesium oxide is an excellent insulator, perfectly isolating the current between the chip and the casing, ensuring safe use.

- Thermal Conduction: Magnesium oxide also has good thermal conductivity, quickly transferring the heat generated by the chip to the entire casing, allowing for uniform heat dissipation, far more efficiently than still air.

- Mechanical Support and Protection: It fills all gaps, secures the fragile chip, cushions stress caused by thermal expansion and contraction, and protects the chip from moisture and contamination.

This application requires magnesium oxide to have extremely high insulation strength, good thermal conductivity, and strict impurity control (especially chloride ion content). Hebei Messi Biology Co., Ltd.’s high-purity magnesium oxide, customized for the electronics industry, is a leader in this field. Its products boast extremely high purity (>99%), excellent insulation performance, stable thermal conductivity, and strictly controlled ionic impurity content through rigorous process control, ensuring the reliability and long lifespan of PTC components in long-term high-temperature working environments. It can be said that behind every safe and stable warmth, there is the silent contribution of such high-performance magnesium oxide.