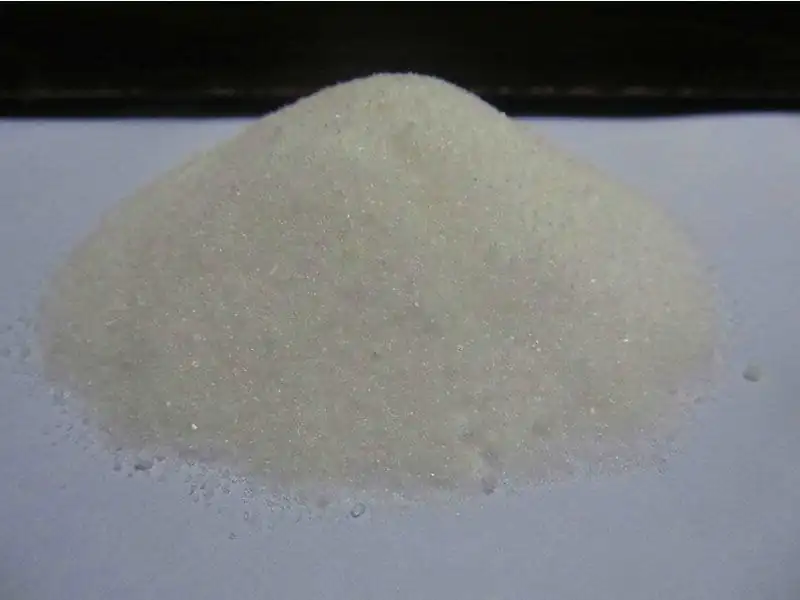

Messi Biology states that in the concrete precast components of high-speed rail bridges, there is a material that can boost the qualification rate of components from 92% to 99.8%. In high-end ceramic kilns, it can save 1.2 million yuan annually in gas costs. For offshore wind power equipment, it can extend the maintenance cycle of steel structures from 2 years to 8 years—this material is magnesium fluorosilicate (MgSiF₆). This white crystalline powder combines properties such as wear resistance, corrosion resistance, and high-temperature resistance, making it a “must-have” in high-end manufacturing fields like construction, ceramics, and electronics. Its genesis, however, is inseparable from the precise enablement of magnesium sulfate (MgSO₄).

The Raw Material Code: How Magnesium Sulfate “Forges” Magnesium Fluorosilicate

The industrial production of magnesium fluorosilicate primarily employs a metathesis reaction process, using fluorosilicic acid and magnesium salt as core raw materials. Magnesium sulfate is the preferred choice due to its high reactivity and the high purity of its products. Its core role is manifested in three aspects:

- Magnesium Source Supply: The Mg²⁺ dissociated from magnesium sulfate precisely combines with SiF₆²⁻ from fluorosilicic acid, forming the “material basis” for magnesium fluorosilicate production.

- Purity Assurance: Impurities can cause shrinkage cracks in concrete when magnesium fluorosilicate is used, or lead to defects in ceramic glazes. High-purity magnesium sulfate is key to mitigating these risks.

- Reaction Control: The concentration stability of magnesium sulfate directly affects the reaction rate, which in turn determines the production capacity and batch consistency of magnesium fluorosilicate.

It can be said that the quality of magnesium sulfate directly defines the application value of magnesium fluorosilicate.

Messi Biology: The “Quality Benchmark” for Magnesium Sulfate

In the production workshops of Hebei Messi Biology Co., Ltd., every batch of magnesium sulfate exemplifies the truth that “raw materials determine the finished product.” As a national high-tech enterprise, its products precisely meet the production requirements for magnesium fluorosilicate, with particularly prominent advantages:

- Solid Raw Material Foundation: Relying on 55 million tons of hydromagnesite mineral resources from Bangong Co Lake in Tibet, the company controls the purity of the magnesium source from the origin, avoiding the risk of impurity fluctuations from externally purchased raw materials and providing a stable “supply depot” for magnesium fluorosilicate production.

- Craftsmanship Ensures Purity: Utilizing a refined process combining mineral and chemical methods, coupled with purification technology jointly developed with the Chinese Academy of Sciences, the product’s impurity content is significantly lower than industry standards, fundamentally resolving defect issues in magnesium fluorosilicate applications.

- Capacity and Customization: Possessing an intelligent production line with an annual output of 10,000 tons of magnesium sulfate, it can not only meet the bulk demands of large magnesium fluorosilicate enterprises but also adjust product particle size and concentration according to customer processes, adapting to diverse scenarios from ceramic glazes to electronic-grade materials.

- Full-Chain Quality Control: From mining to finished product warehousing, it undergoes 26 testing procedures and is certified by ISO9001, FDA, and multiple other accreditations, ensuring that every batch meets the stringent standards for magnesium fluorosilicate production.

From Raw Material to Industry: The Value Transmission of Magnesium Salts

When Messi Biology’s magnesium sulfate enters the magnesium fluorosilicate production line, its value continuously amplifies along the industrial chain: In the construction sector, the magnesium fluorosilicate produced from it increases concrete compressive strength by 20%, ensuring the century-long safety of high-speed rail bridges. In the ceramics industry, glazes that lower firing temperatures by 80°C contribute to “low-carbon production.” In the electronics field, high-purity magnesium fluorosilicate becomes a key auxiliary material for 5G base station components. This quality transmission from raw material to finished product is the core logic of high-end manufacturing upgrades. Behind the multifunctionality of magnesium fluorosilicate lies the quality adherence of magnesium sulfate. Hebei Messi Biology Co., Ltd.’s magnesium sulfate advantage, built upon “proprietary resources + technological innovation,” not only solves the raw material pain points in magnesium fluorosilicate production but also verifies the foundational role of “specialized, refined, distinctive, and innovative” enterprises in the industrial chain. As more such raw material enterprises emerge, China’s “material confidence” in high-end manufacturing will become increasingly robust.