Messi Biology states that magnesium oxide is an irreplaceable key material in mineral insulated cables, and its electrical insulation, thermal stability, and chemical stability determine the safety performance of the cable. The control of its properties, especially purity, hygroscopicity, and particle size, is a core technical aspect in ensuring the manufacturing of high-quality MI cables.

I. The Role of Magnesium Oxide in Insulated Armored Cables

- As an Inorganic Insulating Material

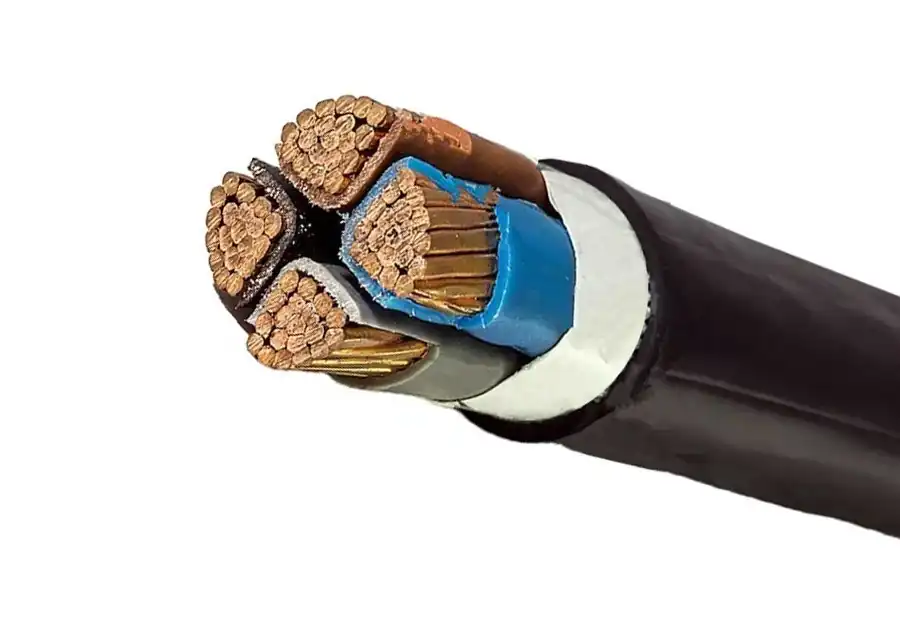

Magnesium oxide (MgO) is an inorganic powder material with a high melting point and high resistivity, widely used in mineral insulated (MI) cables as the insulating medium between the copper conductor and the metal sheath (usually copper or stainless steel). - Providing High-Temperature Stable Insulation

Magnesium oxide can maintain stable insulation performance at temperatures as high as 1000°C or even higher, making this type of cable particularly suitable for high-temperature environments or applications with extremely high fire safety requirements (such as subways, tunnels, nuclear power plants, etc.). - Enhancing Mechanical Strength and Compressive Resistance

Densely packed magnesium oxide powder not only provides electrical insulation but also enhances the mechanical structural strength of the cable, allowing it to resist harsh working conditions such as external compression, vibration, and impact. - Enhancing Fire and Corrosion Resistance

Magnesium oxide has characteristics such as being non-combustible, corrosion-resistant, and non-toxic. In conjunction with the metal sheath, it gives the entire cable structure extremely strong fireproof, high-temperature resistant, and waterproof capabilities.

II. Key Performance Requirements for Magnesium Oxide

To ensure the performance of the cable, the magnesium oxide powder used must meet a series of physical, chemical, and electrical parameter requirements:

- High Purity

- Typical purity requirement: ≥ 99% MgO

- Excessive impurities (such as Cl⁻, SO₄²⁻, Fe₂O₃) will affect insulation resistance, hygroscopicity, and stability.

- Excellent Electrical Insulation Performance

- Resistivity generally required: ≥ 10¹² Ω·cm (at room temperature)

- It must maintain good insulation performance even at high temperatures (e.g., 500–1000°C).

- Low Hygroscopicity

- Magnesium oxide has strong hydrophilic properties, and its insulation performance decreases significantly after absorbing water.

- Therefore, it is required to have a low moisture absorption rate and undergo strict drying and sealed storage procedures.

- Suitable Particle Size Distribution

- The particle size is typically in the range of 10–60 μm, which helps to increase compaction density and reduce air voids.

- If the particle size is too large, it affects filling uniformity; if it is too small, hygroscopicity increases.

- High Thermal Conductivity

- Magnesium oxide has excellent thermal conductivity, which helps to quickly dissipate heat from inside the cable, reducing the operating temperature and extending its service life.

- The general thermal conductivity at room temperature is 20–40 W/m·K.

- High Temperature Resistance

- The melting point of magnesium oxide is approximately 2852°C, and its decomposition temperature is high, allowing it to maintain insulation performance during a fire.

III. Key Points for Usage and Quality Control

- Pre-treatment and Drying: Before use, the magnesium oxide must be dried (e.g., a drying treatment at 300–600°C) to prevent moisture absorption.

- Vacuum Filling and Compaction: Ensure the powder is filled uniformly and densely to avoid voids and partial discharge.

- Storage Requirements: Sealed packaging, moisture-proof, and