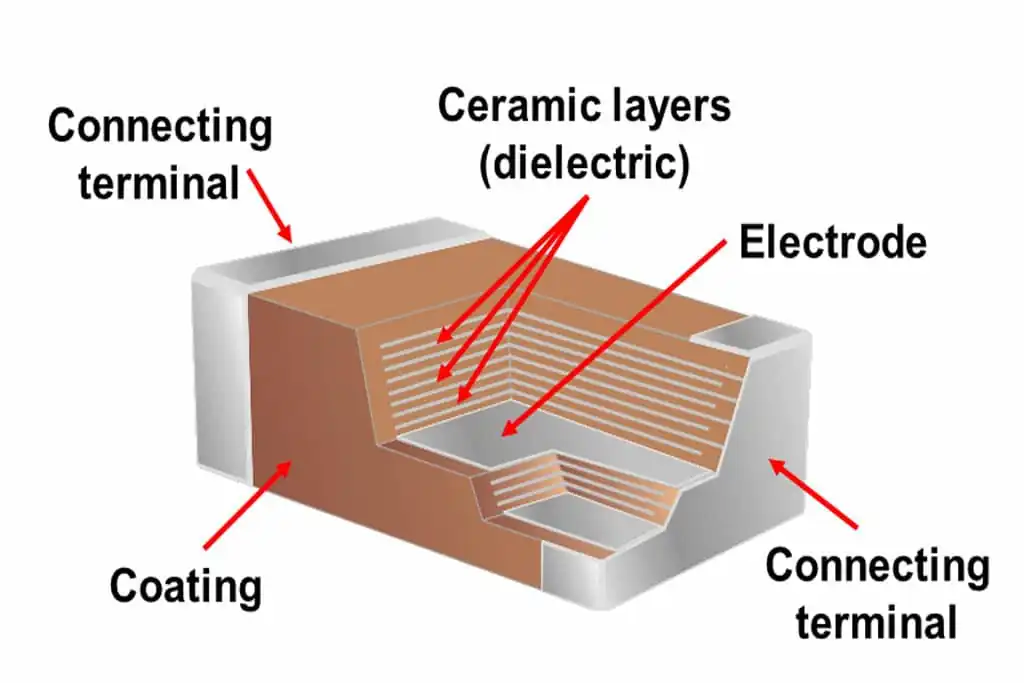

Multi-Layer Ceramic Capacitors (MLCCs) not only handle charge storage and release within circuits but are also key drivers behind the miniaturization and high performance of modern electronic devices. In recent years, with the rapid development of technology, demands on MLCC performance have become increasingly stringent. The introduction of Magnesium Oxide (MgO) as a new type of additive is quietly broadening the application fields of MLCCs, injecting new vitality into the progress of the electronics industry.

Magnesium Oxide: A Catalyst for Performance Improvement

Magnesium Oxide is a white powder known for its high melting point, high hardness, excellent insulation properties, and chemical stability. In the MLCC manufacturing process, traditional electrode materials used are mostly metals like nickel or palladium, while the dielectric layers are typically Barium Titanate (BaTiO3) based ceramic materials. However, as electronic devices evolve towards high frequency and high power density, higher requirements are placed on the capacitance, voltage resistance, temperature stability, and reliability of MLCCs. At this juncture, the addition of Magnesium Oxide has opened a new path for enhancing MLCC performance.

Broadening Application Fields: From Consumer Electronics to Industrial-Grade Applications

1. Innovation in Consumer Electronics

In consumer electronics such as smartphones and tablets, MLCCs are among the core components, and their performance directly affects the overall performance of the device. The addition of Magnesium Oxide significantly increases the dielectric constant of the MLCC. This means that for the same volume, more charge can be stored, thereby improving the device’s endurance capabilities. At the same time, Magnesium Oxide enhances the density and uniformity of the dielectric layer, reduces leakage current, and improves the reliability of the MLCC, allowing consumer electronic products to maintain stable operation even in harsher usage environments.

2. The Leap in Automotive Electronics

With the rise of new energy vehicles and intelligent driving technologies, automotive electronic systems are becoming increasingly complex, leading to a sharp increase in demand for MLCCs. MLCCs modified with Magnesium Oxide can not only maintain excellent performance in high-temperature environments but also withstand the instantaneous high-current surges during vehicle startup, providing a solid guarantee for the stable operation of automotive electronic systems. Furthermore, the addition of Magnesium Oxide improves the vibration and shock resistance of MLCCs, making them more adaptable to the various complex conditions encountered during driving.

3. Expansion into Industrial-Grade Applications

In high-end fields such as industrial control, aerospace, and medical electronics, the performance requirements for MLCCs are even more demanding. MgO-modified MLCCs have successfully penetrated these high-end markets thanks to their characteristics of high capacity, high voltage resistance, and low loss. In the aerospace sector, Magnesium Oxide MLCCs can operate stably under extreme temperature changes and strong radiation environments, ensuring the normal functioning of spacecraft electronic systems. In the field of medical electronics, their high reliability and long lifespan provide strong assurances for patient safety.

With the continuous emergence of new materials and technologies, the application fields of Magnesium Oxide-modified MLCCs will be further broadened. For example, in emerging fields such as 5G communication, the Internet of Things (IoT), and Artificial Intelligence (AI), the demand for high-performance MLCCs will continue to grow.