With the rapid development of the electronics industry, electronic components are becoming increasingly miniaturized and highly integrated. This leads to internal heat accumulation that cannot be dissipated in a timely manner, thereby affecting the performance and service life of these components. Furthermore, today’s most booming industries, such as New Energy Vehicles (NEVs) and Artificial Intelligence (AI), are also facing critical “heat dissipation” challenges.

Polymeric materials, also known as high-molecular materials, are widely used in electronics, electrical appliances, and NEVs due to their excellent electrical insulation, ease of processing, low cost, lightweight nature, and good corrosion resistance. Generally speaking, however, most polymers have poor intrinsic thermal conductivity, making it difficult to meet the heat dissipation requirements of the aforementioned fields.

| Material Name | Thermal Conductivity λ\lambdaλ (W/m·K) | Material Name | Thermal Conductivity λ\lambdaλ (W/m·K) |

| Polyvinyl Chloride (PVC) | 0.13 – 0.17 | Polycarbonate (PC) | 0.193 |

| Polystyrene (PS) | 0.142 | Nylon (PA) | 0.25 |

| Polypropylene (PP) | 0.244 | Polymethyl Methacrylate (PMMA) | 0.180 |

| High-Density Polyethylene (HDPE) | 0.440 | Polybutadiene Rubber (BR) | 0.2 |

(Table: Thermal Conductivity of Polymer Materials at 20°C)

Thermal Fillers to the Rescue

Since most synthetic polymers have poor thermal conductivity, the most common approach to producing materials with good heat transfer characteristics is to fill the polymers with high-thermal-conductivity fillers.

Common thermally conductive fillers can be roughly divided into three categories: metallic fillers, ceramic fillers, and carbon fillers.

Thermal Conductivity of Common Fillers

| Material Name | Thermal Conductivity (W/m·K) | Material Name | Thermal Conductivity (W/m·K) |

| Calcium Oxide (CaO) | 15 | Graphite (C) | 150 – 1500 |

| Silicon Monoxide (SiO) | 1.5 – 1.6 | Aluminum (Al) | 190 |

| Beryllium Oxide (BeO) | 219 | Copper (Cu)* | 380 |

| Boron Nitride (BN) | 29 – 300 | Iron (Fe) | 69 |

| Magnesium Oxide (MgO) | 36 | Alumina ( Al2O3 ) | 30 |

| Silicon Carbide (SiC) | 90 | Silicon Nitride ( Si3N4 ) | 120 |

While metallic particles and carbon materials (such as graphene, single-walled/multi-walled carbon nanotubes, etc.) possess very high intrinsic thermal conductivity—which is beneficial for improving polymer heat dissipation—these fillers often alter the electrical insulation properties of the polymer. For instance, they may result in high electrical conductivity or high dielectric constants, making them unsuitable for polymer-based composite materials that require both high thermal conductivity and excellent insulation. Consequently, the insulation field focuses more on ceramic fillers that possess both high intrinsic thermal conductivity and good insulation properties.

Among all ceramic fillers, Boron Nitride (BN), Alumina (Al2O3), and Aluminum Nitride (AlN) are the most commonly used. While the thermal performance of BN and AlN is outstanding, they are expensive. Alumina has lower thermal conductivity compared to BN and AlN, but its low cost has made it the most widely used. Although the thermal conductivity of Magnesium Oxide (MgO) is lower than that of BN and AlN, at 36 W/(m·K), it is higher than that of Alumina and remains cost-effective. Therefore, MgO is gradually becoming one of the mainstream solutions for thermally conductive fillers.

Magnesium Oxide Fillers: Both Thermally Conductive and Flame Retardant

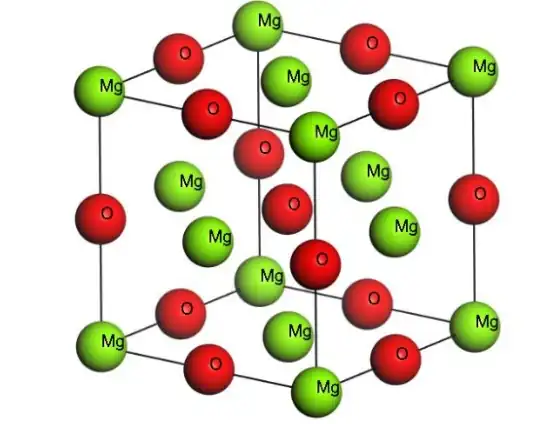

Magnesium oxide, commonly known as magnesia or calcined magnesite, is an ionic compound that appears as a white solid at room temperature. Its chemical formula is MgO. It is odorless, non-toxic, and belongs to the cubic crystal system with a typical NaCl-type crystal structure. Under atmospheric pressure, pure MgO has a melting point of 2852°C and a very high boiling point of around 3600°C. It has a relative density of 3.58 g/cm³ at 25°C and possesses excellent thermal conductivity. MgO is easily soluble in dilute acids but insoluble in water and absolute ethanol.

(Image: Crystal Structure of Magnesium Oxide)

There is a wide variety of magnesium oxide products. Among them, MgO powders with special morphologies have become a focal point of research in recent years. Compared to traditional irregular MgO, magnesium oxide with special morphologies exhibits unique application properties due to its specific surface characteristics. In particular, spherical magnesium oxide offers better thermal conductivity than general MgO. After processing, it can increase the thermal conductivity to 40-60 W/(m·K), which is higher than that of spherical alumina. Furthermore, it allows for a higher filling ratio, offering better cost-performance value.

Additionally, adding magnesium oxide to plastics provides both thermal conductivity and flame retardancy. Generally, plastics have low flame resistance, which can easily lead to accidents. For example, in LED lamps, long-term use generates high internal temperatures; if this heat is not released promptly, accidents can occur. Common flame retardants include zinc borate, alumina, and magnesium oxide. While zinc borate has excellent flame retardant effects and is widely accepted, the limited reserves of boron lead to high prices, which is disadvantageous for cost control. Alumina and magnesium oxide are more readily available. Regarding the effectiveness of these two, spherical magnesium oxide offers superior flame retardancy. Although the preparation process for spherical MgO currently lags behind that of spherical alumina, the industry is very optimistic about the prospects of spherical MgO due to its high-performance flame retardant properties.

Summary

In conclusion, magnesium oxide is an excellent thermally conductive filler that can significantly improve the thermal conductivity of polymer composites. Moreover, by optimizing the shape and size of magnesium oxide—such as producing spherical MgO—its thermal performance can be further enhanced to meet the needs of various application scenarios. This is of great significance for promoting the high-value utilization of magnesium resources and ensuring the safe operation of electronic products and new energy vehicles.