Messi Biology states that in high-end manufacturing sectors such as electronics, automotive, and aerospace, UV (Ultraviolet) cured high-temperature coatings are becoming crucial protective materials. These coatings must simultaneously satisfy the dual demands of “rapid curing” and “high-temperature thermal conductivity.” Magnesium Oxide (MgO), relying on its unique properties, has become the core material for solving this challenge, imparting highly efficient thermal conductivity while safeguarding the coating’s high-temperature stability.

Magnesium oxide’s superiority in thermal conductivity stems from its outstanding physical characteristics. As a natural inorganic compound, its thermal conductivity coefficient is as high as 53W, far exceeding traditional coating fillers, allowing it to rapidly transfer heat in high-temperature environments. More notably, it possesses an ultra-high melting point of 2852°C and excellent electrical insulation (10¹⁵ Ω·m). It maintains structural stability even at temperatures above 300°C, meaning it neither melts and fails due to high temperatures nor poses a risk of electrical short circuits, making it perfectly suited for the working environment of UV high-temperature coatings.

In UV systems, magnesium oxide achieves its thermal conductive properties through a scientific mechanism. As a functional filler, it is uniformly dispersed at a weight ratio of 2%–6% in UV-cured resins such as epoxy and silicone, forming a continuous thermal conductive network. When the coating is in a high-temperature environment, heat is rapidly conducted and diffused through the magnesium oxide particles, preventing localized overheating that could lead to coating cracking or substrate damage. Simultaneously, its wide-bandgap semiconductor properties (band gap of 7–9 eV) allow it to absorb UV light, reducing the degradation of the coating matrix by UV radiation, synergistically enhancing the coating’s weather resistance and service life.

Compared to traditional thermal conductive fillers like aluminum oxide and boron nitride, magnesium oxide demonstrates significant advantages. It is not only lower in cost and environmentally friendly but is also perfectly compatible with the UV curing system, without affecting the coating’s rapid curing characteristics (curing within 1–3 minutes). More uniquely, its surface alkalinity and nano-scale effect can also enhance coating adhesion and wear resistance, allowing both thermal and protective functions to be improved simultaneously. In new energy vehicle battery compartment coatings, the addition of magnesium oxide has increased thermal efficiency by 40% while successfully passing national industry tests, ensuring battery safety.

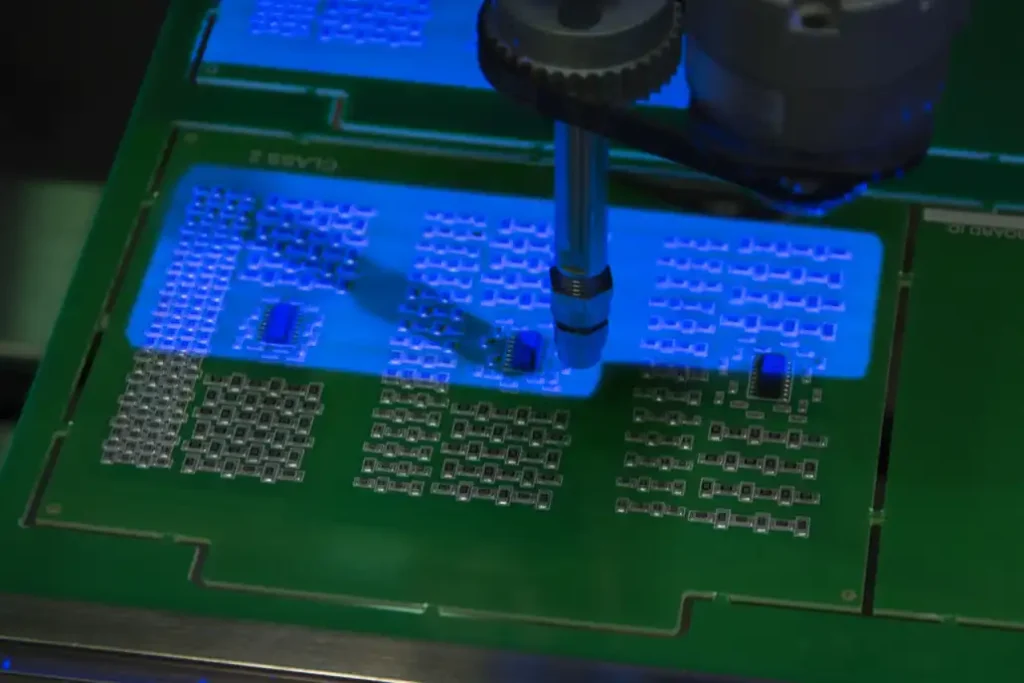

Today, magnesium oxide has been successfully applied in multiple high-end fields: in LED substrate coatings, it boosts device heat dissipation efficiency by 30% and doubles the lifespan; in automotive turbocharger sensor coatings, its wide temperature stability from -60°C to 350°C ensures sensor accuracy; and in 5G base station equipment coatings, it solves the heat dissipation problem of high-density components, assisting stable equipment operation. With the development of nano-modification technology, the application of magnesium oxide in UV high-temperature coatings is expected to become even broader. This “thermal conductivity + protection” multi-functional material is providing highly effective solutions for the high-temperature protection challenges in high-end manufacturing, positioning it as an unsung hero driving industrial upgrading.