The application of activated magnesium oxide in FRP is mainly reflected in the following aspects:

1, As a thickening agent

Activity of active magnesium oxide: the higher the activity, the better the thickening effect.

Particle size of active magnesium oxide: The smaller the particle size, the better the thickening effect.

The amount of active magnesium oxide added: the more added, the better the thickening effect.

Active magnesium oxide has the following advantages as a thickener for FRP:

It thickens quickly and is easy to operate.

Low cost and wide source.

Non-toxic, harmless, environmentally friendly and safe.

2, Improve the gloss of FRP

Activated magnesium oxide has a higher refractive index and can reflect more light, thereby improving the gloss of FRP.

3, Enhance the mechanical properties of FRP

Activated magnesium oxide can fill the gaps in FRP and increase the density and strength of FRP.

4, Improve the heat resistance of FRP

Activated magnesium oxide has high heat resistance and can improve the heat resistance of FRP.

Activated magnesium oxide is used more and more widely in FRP and has become an indispensable additive in FRP production.

Specific application cases are as follows:

In the production of fiberglass reinforced plastic pipes, active magnesium oxide can be used to improve the pressure resistance and corrosion resistance of the pipeline.

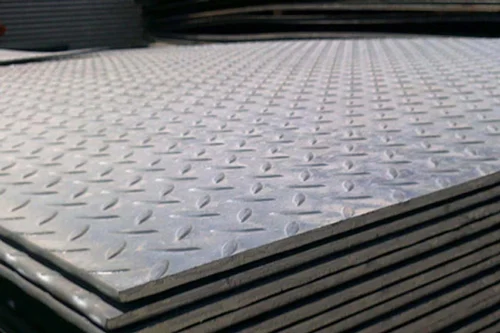

In the production of FRP panels, active magnesium oxide can be used to increase the strength and stiffness of the panels.

In the production of FRP products, active magnesium oxide can be used to improve the surface gloss and weather resistance of the products.

Precautions for use

Activated magnesium oxide should be stored in a dry environment to avoid moisture absorption and caking.

Activated magnesium oxide should be dispersed before use to ensure that it is evenly distributed in the resin.

The amount of activated magnesium oxide added should be adjusted according to the specific application.