Transparent ceramics is a very unique branch of advanced ceramic materials. In terms of its chemical composition, phase structure and preparation process and performance requirements, transparent ceramics is the current advanced ceramics in the field of chemical and phase composition of the most pure, the highest density, the most stringent process requirements, while the performance requirements of the most demanding class of ceramic materials.

Since 1959, the U.S. GE’s COBLE ceramicists successfully prepared the first transparent alumina ceramics, transparent ceramics research and development has entered a new stage, triggered the development of transparent ceramic research and application of the boom. So far, researchers have developed Al2O3、MgO、Y2O3、TiO2、CaO、ThO2、ZrO2 and other oxide transparent ceramics, as well as AlN, ZnS, CaF2, MgF2 and other non-oxide transparent ceramics.

Alumina transparent ceramics are widely used in ceramic discharge tubes for high-pressure sodium lamps and ceramic metal halide lamps in the lighting field, integrated circuit substrates and high-frequency insulating materials in the electronics industry, as well as infrared detection windows because of their high-temperature, corrosion-resistant, high-strength, high-toughness, and good light-transmitting properties, as well as because of the low cost of preparation. Alumina transparent ceramics is a polycrystalline inorganic material, composed of a variety of microstructures, including grains, grain boundaries, the second phase, pores, etc., due to the differences in their respective refractive indices (theoretical transmittance of 86%), resulting in a low transmittance of the material.

Therefore, in the preparation of alumina transparent ceramics, in addition to the use of high-purity raw material powders, it is necessary to add a very small amount of sintering additives to promote the sintering densification as well as the exclusion of porosity during the sintering shrinkage process. In addition, trace amounts of sintering additives also have the effect of inhibiting abnormal grain growth, so the choice of sintering additives and their content is crucial to the final obtainment of high-quality transparent ceramics. Today we will learn about the effect of MgO as a sintering aid on alumina transparent ceramics.

The effect of MgO on alumina transparent ceramics

1, the effect on the relative density

Add the right amount of magnesium oxide alumina transparent ceramics relative density will be improved, but it should be noted that, with the increase in the amount of MgO doping, its relative density has decreased, this is because too much MgO additives will cause an increase in porosity and is not conducive to the densification of the sample. When the addition of MgO is around 0.05%, the relative density reaches 99.5%, and the ceramic samples have very high densification and the highest transmission rate.

At the same time, the relative density of the ceramic samples increased with the extension of the holding time. This indicates that with the prolongation of the holding time, the ceramic grain is further grown and perfected, and the pores in the ceramic samples are further discharged, so that the relative density of the samples is increased. Therefore, the extension of the holding time can get the transparent Al2O3 ceramics with better densities and better light transmittance.

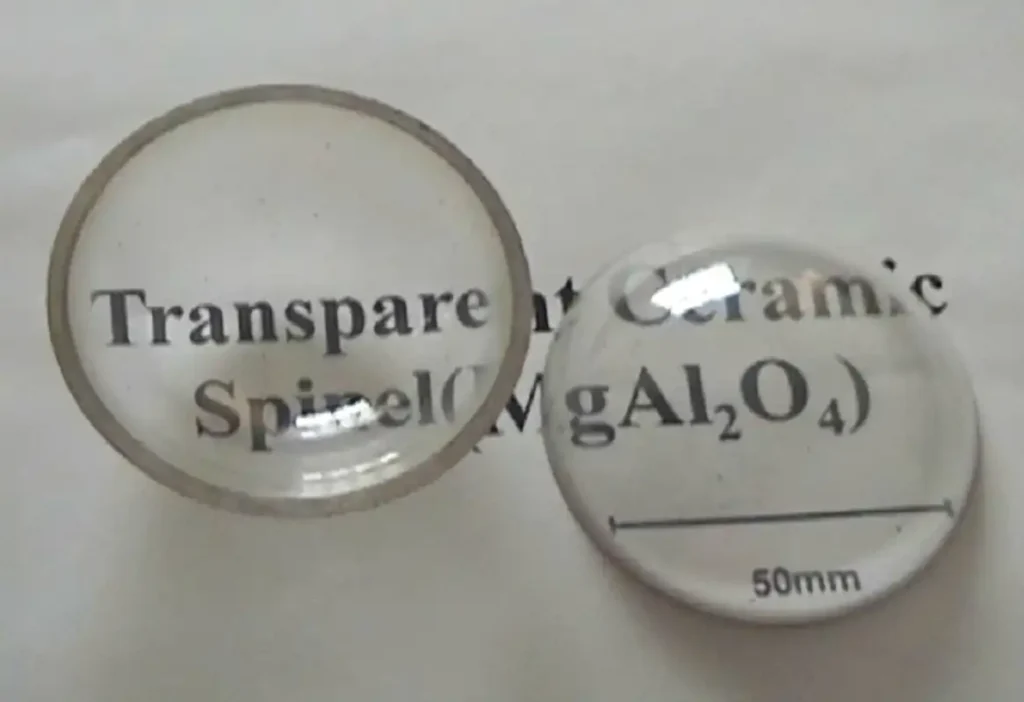

2. Effect on microstructure

The increase in the amount of MgO added, the ceramic grains are finer. This is because the MgO- Al2O3 spinel phase formed in the ceramic can hinder the movement of grain boundaries and inhibit the growth of grains. However, if the addition of MgO is too large, the porosity gradually increases. The reason for this phenomenon may be that too much doping will form a discontinuous liquid phase at the grain boundaries, which makes the tiny pores polymerize into larger pores and remain in them. This kind of porosity exclusion is slow, so when adding too much, the bulk density instead of showing a downward trend.

3, the impact on optical properties

When the doping amount of MgO is low, the light transmittance of transparent ceramics is relatively high, this is due to the appropriate amount of MgO can inhibit the rapid movement of the grain boundaries, so that the pores are discharged more completely, the ceramics are more dense, the transmittance is higher. However, with the increase of doping, MgO content exceeds the solid solubility in Al2O3, the second phase will be formed locally, the formation of light scattering centers, resulting in a decline in the transmittance of transparent ceramics.