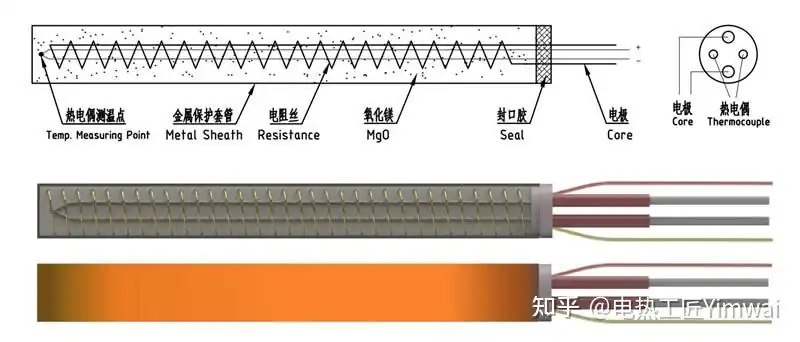

Magnesium oxide mainly has the following functions in electric heating tubes:

(1). Insulation: Magnesium oxide has a high resistivity, which can effectively prevent current leakage between the heating wire and the tube wall, ensuring the safe use of the electric heating tube.

(2). Thermal conductivity: Magnesium oxide has a high thermal conductivity, which can evenly transfer the heat generated by the electric heating wire to the tube wall, improving the heating efficiency of the electric heating tube.

(3). Filling: Magnesium oxide can fill the gap between the heating wire and the tube wall to prevent air from entering and extend the service life of the heating wire.

(4). Protection: Magnesium oxide protects heating wires from mechanical damage and chemical corrosion.

Specifically, the application effect of magnesium oxide in electric heating tubes can be reflected in the following aspects:

(1). Improve the heating efficiency of the electric heating tube: Since magnesium oxide has good thermal conductivity, the heat generated by the electric heating wire can be evenly transferred to the tube wall, thereby improving the heating efficiency of the electric heating tube. According to research, the heating efficiency of electric heating tubes filled with magnesium oxide can be increased by more than 20%.

(2). Extend the service life of the electric heating tube: Magnesium oxide can fill the gap between the heating wire and the tube wall to prevent air from entering, thereby preventing oxidation and corrosion of the heating wire. In addition, magnesium oxide can also absorb the thermal stress generated when the electric heating wire is working, reduce the mechanical damage of the electric heating wire, thereby extending the service life of the electric heating tube.

(3). Improve the safety performance of electric heating tubes: Magnesium oxide has a high resistivity, which can effectively prevent current leakage between the heating wire and the tube wall, ensuring the safe use of electric heating tubes. In addition, magnesium oxide can also absorb the heat generated when the electric heating tube is working, reduce the surface temperature of the electric heating tube, and reduce the occurrence of burn accidents.

Standards for magnesium oxide in electric heating tubes:

(1). Magnesium oxide powder is located between the heating wire and the wall thickness, and is used for the insulation layer between the heating wire and the wall thickness. At the same time, magnesium oxide powder has excellent heat transfer properties. However, magnesium oxide powder has strong water absorption, so it must undergo waterproofing treatment (magnesium oxide powder modified material or electric heating tube sealing treatment) when used.

(2). Magnesium oxide powder can be divided into ultra low temperature powder and high temperature powder according to the temperature range used. Ultra low temperature powder can only be used below 400°C, and is usually magnesium oxide powder treated with modified materials.

In general, the application of magnesium oxide in electric heating tubes has a significant improvement effect and is an indispensable material in electric heating tubes.