Copper clad laminate is the core component of PCB, and PCB is the key support for circuit components and devices in electronic products. PCB is called the “mother of electronic system products”. Its main function is to connect various electronic components to form a predetermined circuit and play the role of relay transmission. Copper-clad laminates are divided into various substrates with different characteristics according to different materials, including paper substrates, composite substrates, special substrates and fiberglass epoxy substrates. The paper substrate has poor strength and is a low-end product. It is generally used in household appliances such as televisions and stereos. The inner film of the composite substrate is impregnated with insulating paper or fiberglass mats with epoxy resin and is also used in household appliances. Glass fiber Fabric-based copper clad laminates are the most widely used, and special material-based copper clad laminates are mostly used in high-power equipment and wireless communication fields.

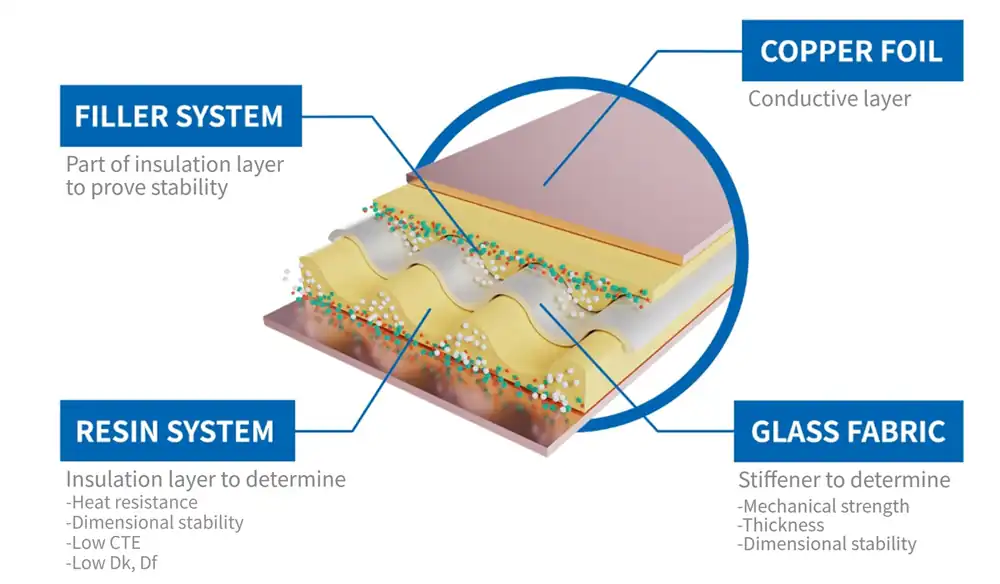

Copper clad laminate is a reinforcing material impregnated with different properties of the resin, add different fillers after drying on one side or both sides of the copper foil, after hot pressing into the plate material. Copper clad laminate substrate filler is generally used inorganic fillers, such as silica fume, talc, aluminum hydroxide, magnesium hydroxide and so on.

Copper cladding board in the crystalline silica micropowder, fused silica micropowder and spherical silica micropowder are used, crystalline silica micropowder started early, the process is mature and simple, the price is relatively inexpensive, but its dispersion, resistance to settlement, impact resistance is not high, the coefficient of thermal expansion is very high, and the hardness is large, processing difficulties. Fused silica micropowder, with lower density (2.2g/cm3), lower dielectric constant, lower coefficient of thermal expansion (0.5×10-6/K), but its melting temperature is higher, for the production capacity of the enterprise higher requirements, process complexity, higher production costs, the general product dielectric constant is too high, affecting the speed of signal transmission.

Spherical silica micropowder has better fluidity, higher filling rate in resin, low internal stress after making plates, dimensional stability, low coefficient of thermal expansion, and has high packing density and uniform stress distribution, so it can increase the fluidity and reduce the viscosity in the filler, and it has a larger specific surface area than angular silica micropowder. Due to the high price of spherical powder and the complexity of the process, the proportion of application in the copper-clad plate industry is not high at present.

And magnesium hydroxide in the application of copper cladding board can meet the high heat resistance requirements of the products, give the products excellent electrical insulation properties, and make it better compatibility with the resin, for improving the surface of the copper cladding board and mechanical properties have obvious effect. Hydroxide flame retardant has high efficiency, strong smoke suppression ability, low hardness, low friction to equipment, which helps to prolong the life of equipment.

Magnesium hydroxide plays an important role in the manufacture of copper clad laminates and is mainly used as a flame retardant. It has the following functions:

1. Flame retardant properties: When magnesium hydroxide is decomposed by heat, it absorbs a large amount of heat and releases water vapor. This process helps to reduce the temperature of the material surface and slow down the combustion process, thereby enhancing the flame retardancy of the copper clad laminate.

2. Environmental protection characteristics: Compared with some traditional halogen flame retardants, magnesium hydroxide is non-toxic, low-smoke, non-corrosive, and more in line with environmental protection requirements.

3. Mechanical and electrical properties: The appropriate addition of magnesium hydroxide can maintain or slightly sacrifice some mechanical strength while not affecting the dielectric properties and electrical insulation of the copper clad laminate, ensuring the safety of the circuit board.

4. Stability: Magnesium hydroxide has stable chemical properties and is not easy to react with other substances, which is conducive to the long-term and stable use of copper clad laminates.

In summary, magnesium hydroxide, through its flame retardant effect and environmental advantages, not only improves the safety of copper clad laminates, but also meets the requirements of the electronics industry for environmental protection of materials.