Messi Biology states that within electronic devices such as smartphones, 5G base stations, and new energy vehicles, there is a hidden key component known as the “Rice of the Electronics Industry”—the Multi-Layer Ceramic Capacitor (MLCC). Acting as a “charge warehouse” in circuits, it is responsible for filtering, bypassing, and energy storage. Magnesium Oxide, though seemingly inconspicuous, is the core hero ensuring its high performance.

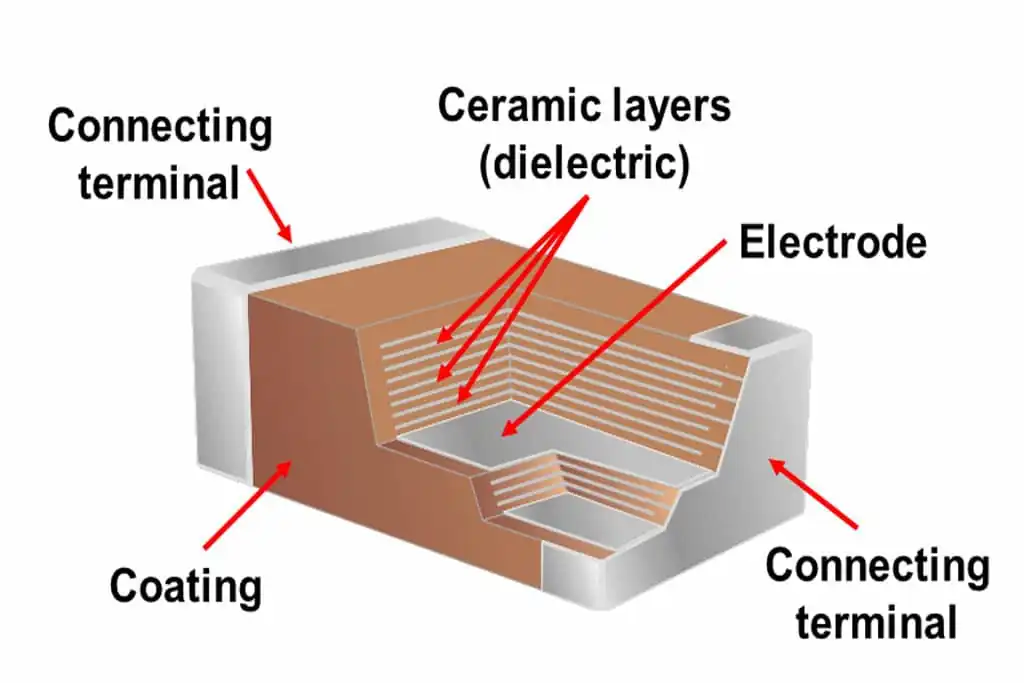

The structure of MLCC ceramics is like an exquisite “mille-feuille” cake, composed of alternating layers of extremely thin ceramic dielectric films and metal internal electrodes, co-fired at high temperatures. The ceramic dielectric is the core factor determining its performance. As a key additive, Magnesium Oxide works in coordination with materials like silicon dioxide and calcium oxide to optimize product characteristics across multiple dimensions. With a melting point as high as 2,852°C, it enables MLCC ceramics to maintain stable electrical performance even in high-temperature environments exceeding 150°C, which is critical for demanding scenarios such as automotive electronics.

In terms of process optimization, Magnesium Oxide plays the role of a “sintering aid.” It can lower the sintering temperature of MLCC ceramics to 1,320–1,350°C, which not only reduces energy consumption but also promotes ceramic densification and shortens production cycles. Simultaneously, it fills microscopic defects within the ceramic and enhances the material’s impact and wear resistance—acting as “protective clothing” for the ceramic dielectric and extending the service life of the device.

The enhancement of electrical performance is the core value of Magnesium Oxide. As an insulating medium, high-purity Magnesium Oxide can control the fluctuation of the MLCC ceramic’s dielectric constant within ±2%, ensuring product consistency. With a dielectric constant stable between 9.8 and 10.2, it can optimize dielectric loss by adjusting the crystal structure to meet the requirements of high-frequency and high-voltage circuits. More importantly, it can reduce ceramic conductivity and significantly increase insulation resistance, preventing the risk of leakage. However, not all Magnesium Oxide is fit for MLCC manufacturing. Electronic-grade Magnesium Oxide must reach a purity of over 99.9%, with impurities such as iron, sodium, and potassium controlled at the ppm (parts per million) level; otherwise, it will introduce electrical defects and degrade dielectric performance. Particle size selection is also precise: nano-scale Magnesium Oxide (20–50nm) is preferred for high-frequency scenarios, while micro-scale products (0.5–2μm) may be used for cost-effective formulations.

With the advancement of 5G communications and the new energy vehicle industry, the demand for miniaturization, high frequency, and high reliability in MLCCs is becoming increasingly urgent. By virtue of its unique high-temperature resistance, excellent dielectric properties, and ease of processing, Magnesium Oxide has become an indispensable material for high-end MLCC ceramics. This “invisible hero” hidden within electronic components continues to support the rapid development of the modern electronics industry through constant technological upgrades.