Messi Biology states that magnesium oxide (MgO) plays an indispensable role as a “key excipient” in oxytetracycline injections (aqueous injections). Through chelation, it simultaneously solves the two core technical challenges of oxytetracycline: low solubility and chemical instability. It is the core component that allows oxytetracycline to be formulated into a stable, effective, and usable injectable dosage form. This is a classic and critical pharmaceutical application focused on improving the solubility and stability of the solution.

Core Mechanism: Chelation and Solubilization

1. Inherent Properties of Oxytetracycline:

- Low Solubility: Oxytetracycline is an amphoteric compound, but its free acid form has very poor solubility in water, making it impossible to directly prepare high-concentration aqueous injections.

- Chemical Instability: Oxytetracycline is highly unstable in acidic or neutral aqueous solutions and is prone to degradation, which reduces efficacy and may produce toxic by-products.

2. The Role of Magnesium Oxide as a Chelating Agent:

- Magnesium oxide (MgO) generates magnesium hydroxide [Mg(OH)₂] in water, providing magnesium ions (Mg²⁺).

- The molecular structure of oxytetracycline contains multiple phenolic hydroxyl and enolic groups. These groups undergo a strong chelation reaction with magnesium ions (Mg²⁺) to form a stable, water-soluble oxytetracycline-magnesium complex.

Specific Benefits of Magnesium Oxide

1. Increased Solubility:

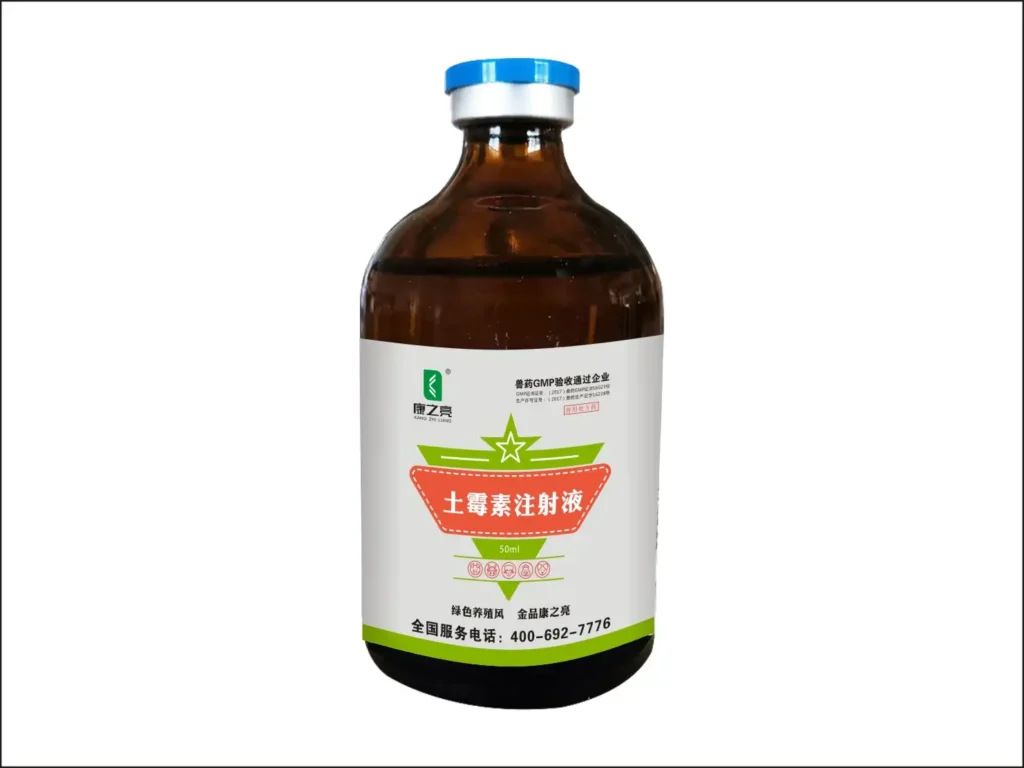

- The resulting oxytetracycline-magnesium complex is hydrophilic, and its solubility in water is far greater than that of oxytetracycline itself. This makes the preparation of high-concentration injections (such as the common 5%, 10%, and 20% concentrations) possible.

2. Enhanced Stability:

- Chelation “locks” the active groups in the oxytetracycline molecule that are susceptible to degradation reactions, thereby significantly slowing down its decomposition rate in solution and extending the drug’s shelf life.

- The resulting complex solution is typically alkaline (pH approximately 8.0–9.5), an environment that is more conducive to the stability of oxytetracycline.

3. Reduction of Local Irritation:

- High-concentration oxytetracycline solutions are inherently irritating to muscle tissue and can cause pain, swelling, or even necrosis at the injection site.

- After forming the complex, the properties of the solution become milder, which reduces irritation during intramuscular injection to a certain extent.

Brief Description of the Preparation Process:

- Chelation: Mix magnesium oxide with oxytetracycline powder, add a small amount of water or solvent, and grind to allow full chelation.

- Excipient Addition: Add other excipients (such as procaine, antioxidants, co-solvents, etc.).

- Final Formulation: Add water to the total volume, adjust the pH to a stable range (usually 8.0–9.5), filter, fill, seal, and sterilize.