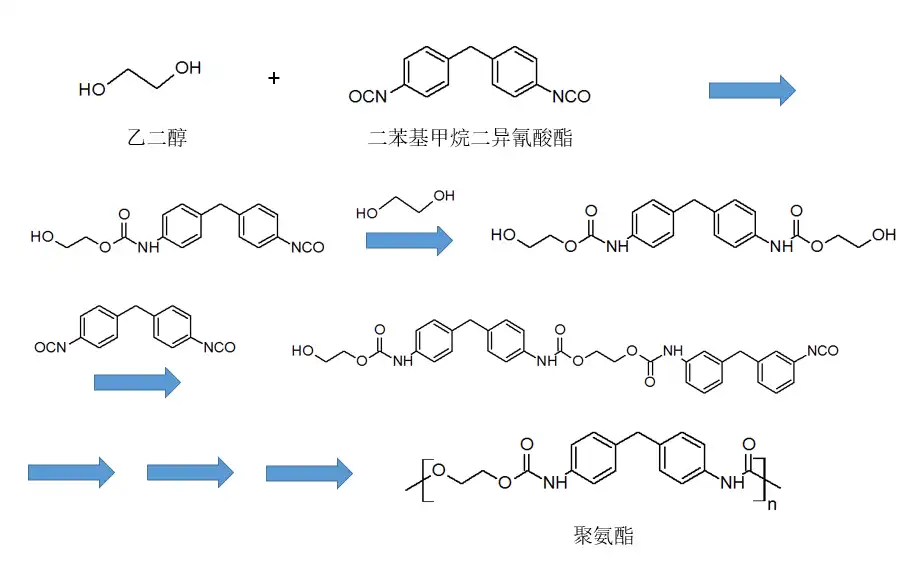

Magnesium oxide is an alkaline oxide. In the polyurethane (PU) catalyst system, magnesium oxide mainly plays the role of auxiliary catalysis and stabilization of the system. Polyurethane is a polymer generated by the reaction of polyols and isocyanates, and its reaction process requires a catalyst to control the reaction rate and selectivity.

As an acid absorbent

During the synthesis of polyurethane, acidic by-products are produced. For example, the reaction of isocyanate with water will produce carbon dioxide and amines, and release a small amount of acidic substances. Magnesium oxide can be used as an acid absorbent to neutralize these acidic by-products. Its reaction formula is, which can prevent the influence of acidic substances on the activity of the catalyst, maintain the pH balance of the reaction system, and thus ensure the smooth progress of the polyurethane synthesis reaction.

Adsorption and anti-agglomeration

Magnesium oxide has certain adsorption properties. It can adsorb some impurities or unreacted small molecules in the reaction system, such as unreacted polyols or isocyanate monomers. In polyurethane production, nano-magnesium oxide can be adsorbed on the surface of polymer particles to prevent particle agglomeration. For example, when preparing polyurethane foam, magnesium oxide can make the foam pores more uniform and improve the quality and stability of the foam. Because it prevents excessive fusion or rupture of the cell wall during the formation process, making the cell structure more regular.

Synergistic catalytic effect

When magnesium oxide is used in combination with other polyurethane catalysts (such as organotin catalysts, tertiary amine catalysts, etc.), a synergistic catalytic effect can be produced. Taking organotin catalysts as an example, organotin mainly catalyzes the reaction between isocyanate and hydroxyl (gel reaction), while magnesium oxide can adjust the reaction activity to a certain extent, making the reaction more stable. In some cases, magnesium oxide can improve the selectivity of organotin catalysts, promote specific reaction paths, accelerate the growth and cross-linking reaction of polyurethane molecular chains, and thus improve the physical properties of polyurethane products, such as hardness and tensile strength.

Contribution to thermal stability

Magnesium oxide can improve the thermal stability of polyurethane materials. In high temperature environments, polyurethane materials are prone to thermal degradation. Magnesium oxide can absorb heat and, to a certain extent, prevent heat transfer, delaying the thermal decomposition process of polyurethane molecular chains. At the same time, it can also react with free radicals generated during thermal degradation, inhibiting the progress of free radical chain reactions, thereby improving the service life and use temperature range of polyurethane materials. For example, polyurethane sealing materials used in high temperature environments can better maintain their sealing properties after adding magnesium oxide.