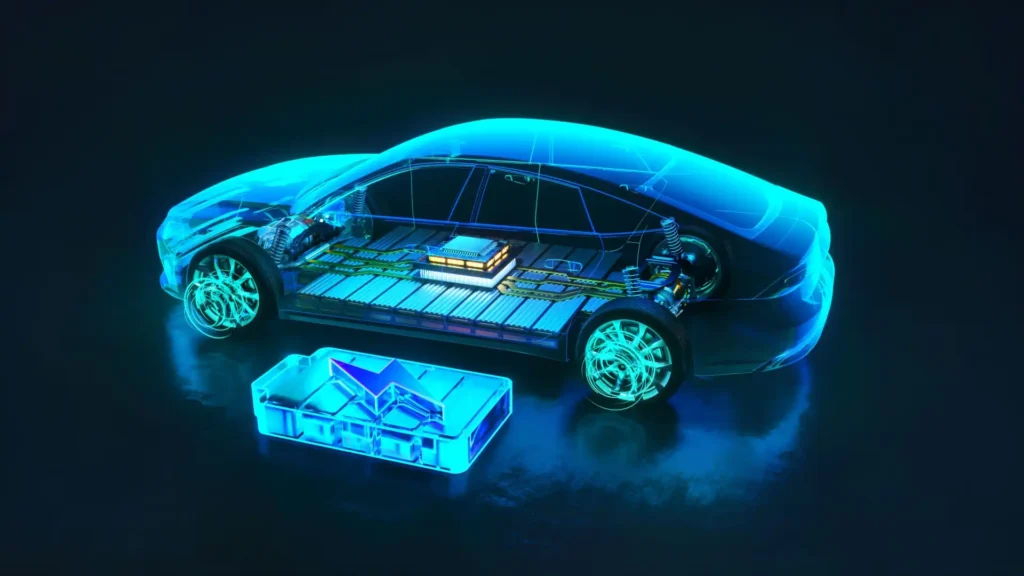

Messi Biology states that in the race for battery technologies with higher energy density and absolute safety, solid-state batteries (SSBs) are hailed as the “holy grail” of next-generation energy storage. By replacing the flammable and explosive liquid electrolytes in traditional lithium-ion batteries with robust solid-state electrolytes, they promise to simultaneously address both “range anxiety” and “safety concerns.” However, the journey of this disruptive technology from laboratory to industrialization faces numerous challenges. Surprisingly, a seemingly ordinary material—magnesium oxide (MgO)—is emerging as one of the key additives to overcome these obstacles, thanks to its unique properties.

The Achilles’ Heel of Solid-State Batteries

At the core of solid-state batteries lies the solid electrolyte. One of the current mainstream technical routes involves oxide electrolytes, such as the well-known LLZO (Lanthanum Lithium Zirconate Oxide) and LLZTO (Tantalum-doped LLZO). These materials boast good chemical stability and high mechanical strength, but they possess a fatal weakness: interface issues.

Magnesium Oxide: The ‘Interface Master’ Achieving Significant Impact with Minimal Input

It is precisely in the process of resolving these challenging interface problems that researchers have discovered the ingenious application of magnesium oxide. When introduced as a minor additive into cathode materials or electrolytes, it performs wonders, achieving significant impact with minimal input:

Excellent Interface Stabilizer: Magnesium oxide possesses extremely high chemical and electrochemical stability. On the surface of the cathode material, it forms an ultra-thin protective coating, acting like “sunscreen” to effectively isolate the active cathode material from direct contact with the solid electrolyte. This significantly inhibits detrimental interfacial side reactions and extends battery life.

A ‘Bridge’ for Promoting Ion Transport: Studies have shown that during the sintering and preparation of electrolytes like LLZO, adding nano-magnesium oxide acts as a sintering aid, lowering the sintering temperature, promoting electrolyte densification, and reducing grain boundary resistance. Concurrently, it optimizes the lithium-ion transport channels within the electrolyte, enhancing overall ionic conductivity.

Enhanced Mechanical Properties: Nanoscale magnesium oxide particles also act like reinforcing fibers in “reinforced concrete,” improving the mechanical strength of the electrolyte sheets. This makes them less prone to breakage during battery assembly, thereby increasing process yield.

Despite its minimal addition (typically 1%-5%), nano-magnesium oxide enhances the overall performance of solid-state batteries across multiple chemical and physical dimensions, making it a true “all-rounder assistant.”

China’s Outstanding Contribution: Hebei Messi Biology Co., Ltd.’s Magnesium Oxide Advantages

Given the critical role of magnesium oxide as an additive, its inherent quality is naturally paramount. Indicators such as purity, particle size distribution, and surface activity directly determine its ultimate effectiveness. In this field, Hebei Messi Biology Co., Ltd., leveraging its extensive technical expertise, produces high-end magnesium oxide products perfectly suited for solid-state battery applications.

Extremely High Product Purity: Messi Biology, through precise process control, can provide high-purity magnesium oxide with purity exceeding 99.95%. Extremely low impurity content (especially elements like iron and chlorine) is crucial, as it prevents impurities from triggering side reactions within the battery, thus ensuring long-term cycle stability and safety.

Precise Particle Size Control: The company’s technology enables the production of ultra-fine nano-magnesium oxide powder with uniform particle size distribution. The nanoscale dimensions ensure that the additive can uniformly coat the surface of the cathode material or disperse within the electrolyte, forming an effective thin layer that does not hinder ion transport, thus maximizing its interface modification capabilities.

Excellent Dispersibility and Stability: Specifically for battery material preparation processes, its magnesium oxide products exhibit excellent dispersibility, making them easy to uniformly mix with cathode material precursors. This prevents agglomeration from affecting performance and offers great convenience to battery manufacturers.

With the breakthroughs in solid-state batteries, this classic material, magnesium oxide, is experiencing a new vitality in high-tech fields. As the industrialization process of solid-state batteries accelerates, the demand for high-performance, high-specification magnesium oxide will undoubtedly grow. And companies like Hebei Messi Biology Co., Ltd., by continuously providing high-quality advanced magnesium materials, are quietly becoming “invisible champions” supporting the innovative development of China’s new energy industry, contributing crucial strength to building a safer and more efficient energy future.