With the development of society, people have more and more demands for tires. From bicycles, cars, and agricultural vehicles to baby carriages, toy cars, balance cars and other products, the requirements for tires are different according to different uses. Light magnesium oxide is a very important material added to them.

1. The basic concept of light magnesium oxide

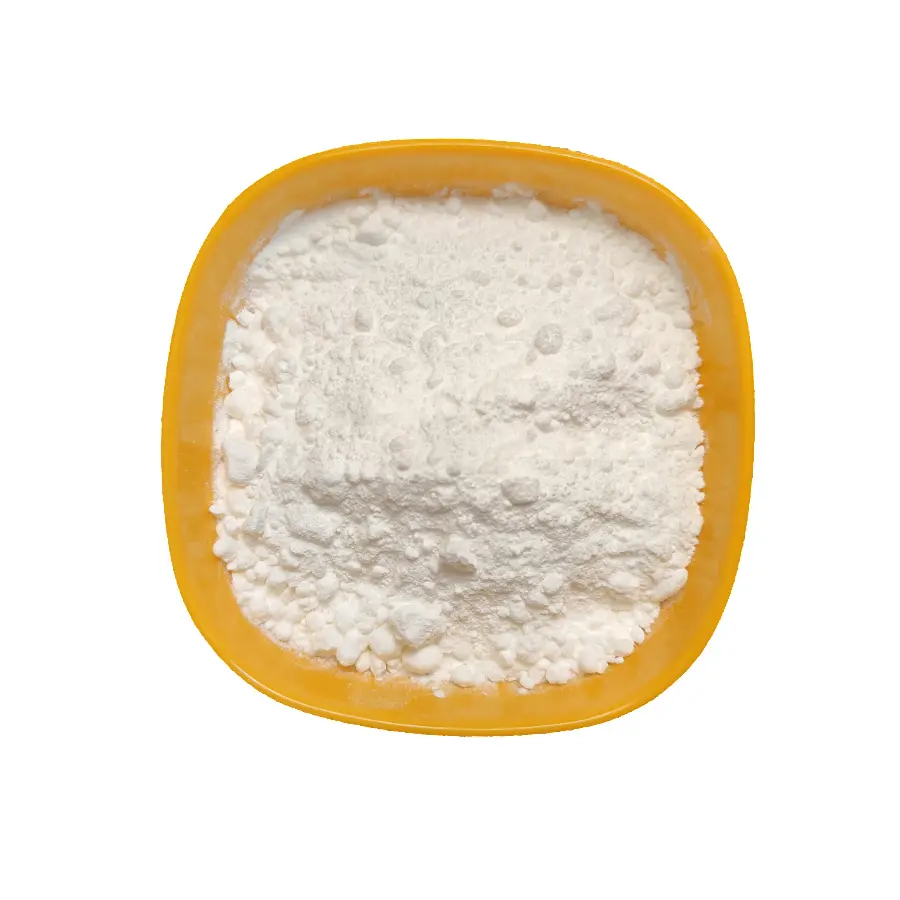

Light magnesium oxide is an odorless, tasteless, non-toxic, white loose amorphous powder. The volume occupied by light is about three times that of heavy magnesium oxide, and it is an important inorganic compound. It is widely used in tires, rubber, ceramics, building materials, metallurgy, chemicals, food, medicine and other industries.

2. The role of light magnesium oxide added to tires

The addition of light magnesium oxide will play the role of anti-scorching agent, vulcanization accelerator, acid absorber, filler, high temperature resistance, fire retardant and corrosion resistance in the production process of tires. Secondly, light magnesium oxide has a certain activity, which is beneficial to improve product quality, and can prolong the scorch time and improve the flexibility and wear resistance of the product. Furthermore, adding lightweight magnesium oxide can accurately control the rubber content and adhesion performance of the tire, effectively improve the physical properties of the rubber, control the tensile strength and dynamic compression deformation and heat generation problems, and reduce the occurrence of quality problems. In addition, it also tries to avoid tire blowouts and wheel hub detachment when the vehicle is running at high speed or carrying loads.

3. Precautions

There are many details that cannot be ignored in the use of lightweight magnesium oxide. First of all, pay attention to moisture-proof treatment. Once lightweight magnesium oxide is damp, excessive hydrochloric acid insolubles and water-solubles will cause blistering and sand eyes; secondly, too low magnesium oxide content will affect its toughness and wear resistance; thirdly, too high calcium content will cause fractures; finally, if too little lightweight magnesium oxide is added, the cross-linking density will increase while shortening the scorch time and positive vulcanization time, affecting the tensile strength, tensile stress, hardness, and elongation of the product. So pay special attention when selecting and storing products!