Messi Biology states that magnesium oxide (MgO) is not merely an optional filler in energetic materials (explosives, propellants, igniters, etc.) but rather an invisible engineer influencing the “performance, safety, and process” triad. With its triple advantages of “high melting point, high chemical inertness, and low cost,” magnesium oxide is propelling energetic materials toward the next generation of higher energy, lower risk, and greener manufacturing.

- “Desensitizing and Stabilizing” Dual-Effect Agent in Explosive Systems

- Desensitization Mechanism: Nano-magnesium oxide forms a nanoscale heat-insulating/gas-insulating layer on the surface of explosive grains, reducing sensitivity to mechanical impact, static electricity, and friction. When synthesizing lead trinitroresorcinate (LTNR) using a microreactor, introducing a small amount of MgO can make the crystal morphology more regular and the particle size distribution narrower, reducing impact sensitivity by 30%.

- Acid Suppression and Corrosion Inhibition: Acidic by-products generated during decomposition or long-term storage can accelerate the self-decomposition of explosives. MgO, as an acid scavenger, can extend the storage life to more than 15 years.

- “High-Energy, Low-Ablation” Framework for Solid Propellants

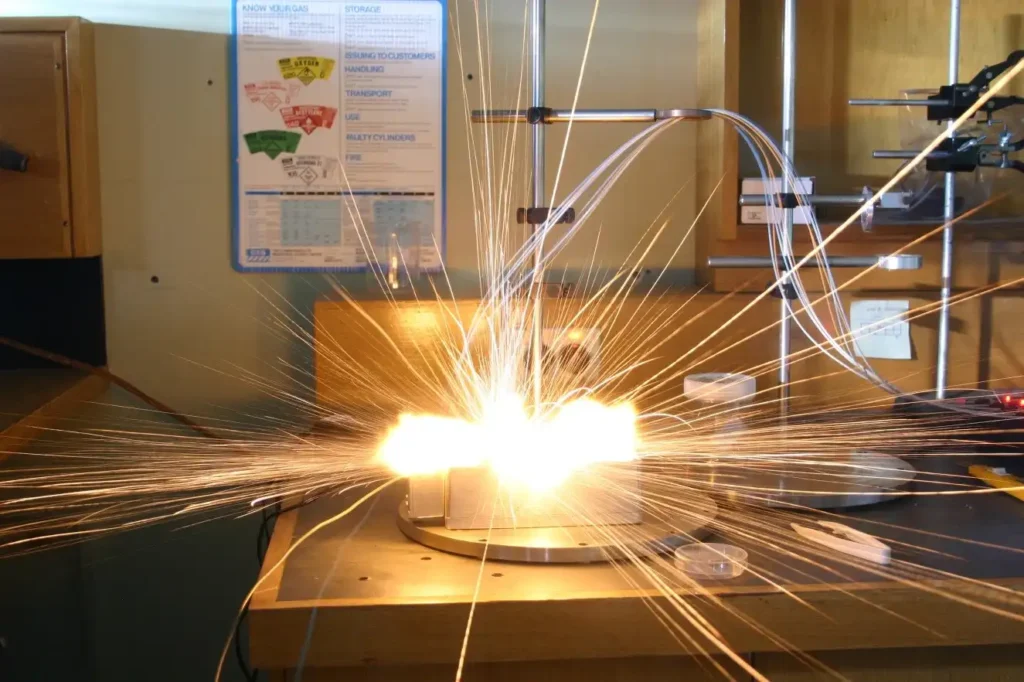

- Combustion Catalyst: In AP/Al/HTPB composite propellants, 2–5wt% nano-MgO can reduce the high-temperature decomposition temperature of AP by about 60℃, increase the linear burning rate by 8–12%, and make the flame temperature distribution more uniform.

- Prevention of Nozzle Ablation: MgO generates a high-melting-point ceramic phase (>2200℃) at high temperatures, forming a self-healing heat-insulating layer on the inner wall of the nozzle, reducing the linear ablation rate of the throat diameter by 40%, which has been verified in a certain type of tactical missile.

- “Second-Level Temperature Control Valve” for Igniters and Delay Compositions

- Thermal Buffer Layer: Adding ultrafine MgO to boron/potassium nitrate igniters utilizes its high thermal conductivity + high enthalpy change characteristics to precisely adjust the ignition delay time from 3ms to 10ms, meeting the needs of multiple simultaneous detonations.

- Mars Propellant: In Mars missions, Mg/CO₂ dual-component engines use light-burning Mg powder + magnesium oxide combustion aid as fuel, and a 200kg-class prototype has achieved 10–15 jumps with a cumulative range of 15km.

- Process Safety and Green Manufacturing

- Microfluidic Continuous Production: In segmented flow microreactors, MgO acts as both a crystal form control template and a flow aid, which can reduce the hazard level of traditional kettle processes from level 3 to level 1, and shorten the single batch time from hours to minutes.

- Environmental Protection Replacement: Replacing traditional heavy metal desensitizers (such as Pb, Sb compounds) to meet REACH and IMCO green regulations.

Outlook

- Nano-porous magnesium oxide (pore size 50–200nm) will be used for CL20-based high-energy, low-sensitivity explosives.

- Magnesium oxide-coated aluminum powder (MgO@Al) is breaking through the energy limit of metallized solid propellants (theoretical specific impulse >270s).