Background and Overview

Basic magnesium carbonate is also known as “light magnesium carbonate”. Chemical formula xMgCO3-yMg(OH)2-zH2O (x=3~5, y=1, z=3~7). Typical molecular formula is 3MgCO3-Mg(OH)2-3H2O, molecular weight 365.31. white crystal or amorphous light, loose powder. specific gravity 2.16. insoluble in water. Specific gravity 2.16. Insoluble in water, ethanol, soluble in acid, while releasing carbon dioxide. Decompose by heating; release carbon dioxide and water, and turn into magnesium oxide at 700℃. It is obtained by the reaction between magnesium hydroxide emulsion and carbon dioxide or the reaction between soluble magnesium salt and sodium carbonate mixed in certain concentration.

Hydrated basic magnesium carbonate is stable in air, the chemical composition is slightly different due to different preparation methods and conditions, its relative density is small, it can be used as additives for rubber and plastic products, at the same time it has the characteristics of non-combustible, it can be used for the preparation of magnesium oxide after thermal decomposition, food grade basic magnesium carbonate can be used as flour improver. Basic magnesium carbonate can be used as an excellent filler for rubber products, enhancement agent and fire insulation materials for adiabatic and high temperature resistance. It is also used to make magnesium salt, magnesium oxide, fireproof coating, printing ink, ceramics, glass, cosmetics, toothpaste, medicine and pigment. For some special-purpose alkaline magnesium carbonate, according to its different uses, the impurity requirements are also different. For example, when used as raw material for making refractory material – high purity magnesium oxide, the content of calcium oxide and boron impurities is required to be very low, because B2O3 in the product and CaO, SiO2 and other impurities will form various low eutectic compounds under high temperature conditions, which will make the high temperature performance of the refractory material decrease. Therefore, basic magnesium carbonate in the production of high-purity magnesium oxide as raw materials, CaO, the content of the assessment of the product is one of the important indicators of the merits of the product, the less its content, the better. For electronic grade basic magnesium carbonate, it should not only have high purity, but also have special physical properties. Therefore, in the production of basic magnesium carbonate, according to the specific use of the product to determine the specific standards of its products. However, in general the purity of the product determines the application range of the product.

Preparation

At present, China’s basic magnesium carbonate production methods are: brine soda ash method, magnesium carbonate ammonium sulfate method, dolomite carbonization method, light burning powder carbonization method.

1, brine soda ash method

Brine soda ash method is the oldest method of producing basic magnesium carbonate, in our country there have been sixty or seventy years of production history. Although the production method is old, at present it is still a production method with the highest output and product grade of magnesium carbonate. The method is the use of coastal salt brine, after a series of processes, such as removal of impurities and iron, prepared to a certain degree of boeum, and dissolved and de-immersed soda ash solution at a certain temperature for the reaction, resulting in magnesium carbonate base. After centrifugation or press filtration, it is washed repeatedly with deionized water until the chlorine ion reaches the requirement. The filter cake is dried to get the basic magnesium carbonate product; the filter cake is directly calcined to get the magnesium oxide product. Control the reaction temperature and reactant concentration, can get different stack density products, that is, can get heavy magnesium carbonate or light magnesium carbonate. It is understood that now domestic only Shandong Shouguang have two or three enterprises using the method for production, two of them to produce light magnesium oxide, a production of heavy magnesium carbonate is mainly D Two production of light magnesium oxide enterprise annual output of light magnesium oxide are not more than 2,000 tons, mainly because of the method of higher production costs, and its products corresponding to the market demand is not large. And the production of heavy magnesium carbonate enterprise is almost workshop production, the annual output of only a few hundred tons.

2, Magnesium carbonate ammonium sulfate method

With purified magnesium sulfate solution and ammonium carbonate solution for the reaction, you can make basic magnesium carbonate. Adjust the concentration of reactants and reaction temperature, you can get different pile density of basic magnesium carbonate. The reaction product is washed and filtered repeatedly to make the product meet the quality requirements. At present, there are few domestic enterprises using this method to produce basic magnesium carbonate, and it is understood that there may be only one in the production . The products can be sold as basic magnesium carbonate products, or basic magnesium carbonate calcined into magnesium oxide for sale. This is the main method of producing pharmaceutical grade and food grade magnesium carbonate and magnesium oxide. But the output is very small, only a hundred tons a year, at most a few hundred tons of production and sales.

3, dolomite carbonization method

Dolomite carbonization method is the calcination of dolomite, the dolomite ash obtained (the main components of calcium oxide and magnesium oxide) for hydration, to get magnesium hydroxide and calcium hydroxide mixture. The tail gas of calcined dolomite is purified, and its content of carbon dioxide is about 30%, after compression, it reacts with the dolomite ash hydration solution in the carbonization tower, and obtains calcium carbonate precipitation and magnesium bicarbonate solution. After the reaction solution is precipitated and filtered, the magnesium bicarbonate solution is sent to pyrolysis to get basic magnesium carbonate. After the pyrolysis solution is filtered and washed, the basic magnesium carbonate filter cake is obtained. Filter cake drying, get basic magnesium carbonate products; filter cake calcination, then get light magnesium oxide products. This is all the production of basic magnesium carbonate method in the highest energy consumption, the process route is the longest production method, the domestic probably only two to three enterprises using this process for production. According to the magnesium oxide counts some enterprises annual output reaches a thousand tons, some still less than a thousand tons, product quality varies. This method produces magnesium carbonate and magnesium oxide with large apparent specific volume, and it is the main method to make magnesium carbonate, light magnesium oxide and active magnesium oxide with large apparent specific volume. Some enterprises to get the basic magnesium carbonate filter cake molding, drying, processing into gymnastics magnesium block sold at home and abroad, has a relatively high added value.

4, light burning powder carbonization method

Lightly burned powder is also called lightly burned magnesium oxide. Lightly burned powder carbonization method in fact the principle and dolomite carbonization method is similar. Calcined magnesite, control the calcination temperature in a certain range, you can get light burning magnesium oxide. Lightly burnt magnesium oxide is hydrated with water to get magnesium hydroxide slurry. Calcined magnesite after the tail gas is purified, compressed and then sent to the carbonization tower, and light burning powder hydration slurry reaction, get magnesium bicarbonate solution, after further precipitation and filtration, magnesium bicarbonate solution is sent to the pyrolysis, get magnesium alkali carbonate, and then filtered and washed, that is, get alkali magnesium carbonate filter cake. Now there are about one or two domestic enterprises using this method to produce basic magnesium carbonate or magnesium oxide, the annual output of about one or two thousand tons. China’s Liaoning once there are several enterprises, in the magnesite near the plant, the production of basic magnesium carbonate. Despite the advantage of raw fuel, but due to the smaller market, finally all had to stop production.

Identification

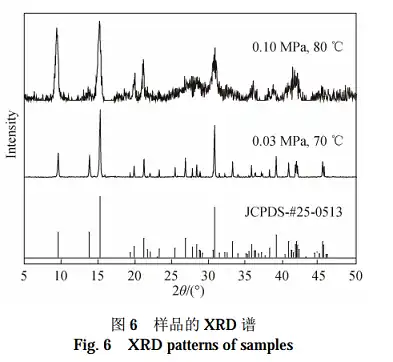

The following figure shows the XRD spectrum of the sample.

Application

Basic magnesium carbonate can be broadly categorized into three areas according to its uses.

(1) Used as an additive and improver for food and various chemical products;

(2) Used as raw material for the preparation of magnesium series chemical products;

(3) Used in pharmaceuticals and medicine as an adjunct to therapeutic drugs.

It has been reported that the basic magnesium carbonate made into magnesium aluminum carbonate compound salt with ranitidine capsule, amoxicillin capsule, metronidazole tablets, etc. can greatly improve the cure rate of peptic ulcer in the elderly. Magnesium aluminum carbonate also plays an important role in the treatment of ulcers. It can raise the pH value of the stomach and promote tissue regeneration and repair. As the elderly ulcer tissue regeneration and repair of the mantle, taking magnesium aluminum carbonate can make its direct effect on the ulcer surface, promote tissue regeneration, improve the ulcer healing rate. High purity magnesium carbonate alkali non-toxic, tasteless, harmless to human health, and magnesium on the human heart function has enhanced its own good mobility, so it will be added to the flour as an auxiliary ingredient, not only can improve the dispersion of flour and mobility, but also supplement the human body to the inorganic salts, such as the demand for electrolytes, the amount of additive is generally 10% ~ 15%. In chemical metallurgy, basic magnesium carbonate can also be used as an additive in some alloys to change the mechanical properties of alloys.

Basic magnesium carbonate can also be used as a good filler and reinforcing agent for rubber products, which can improve the yield and quality of rubber products. Refined transparent magnesium carbonate base can also be used in transparent or light-colored rubber products, it and rubber mixing, almost does not change the refractive index of the rubber itself, and can enhance the abrasion resistance, flexural resistance and tensile strength of rubber. Due to the non-combustible and lightweight, loose characteristics of basic magnesium carbonate, can also be used as insulation, high temperature fire insulation materials, asbestos lightweight magnesium carbonate is an excellent insulating material, used in shipbuilding, boiler manufacturing and other sectors. In addition, it can also be used for paint, ink and coating and other industries.

Market Outlook

As a direct product, the annual demand of China’s magnesium basic carbonate market is only one or two thousand tons, which includes all light and heavy magnesium basic carbonate products. The use of basic magnesium carbonate is still further calcined, as magnesium oxide products for sale. In recent years, several large magnesium salt enterprises in Qinghai of China have produced high quality and low cost magnesium hydroxide products, whose output is counted in hundreds of thousands of tons. These magnesium hydroxide are mainly processed into magnesium oxide products for sale in the market, forming a strong competition to the magnesium oxide produced by basic magnesium carbonate. Under such competition, in recent years, many basic magnesium carbonate production enterprises shut down, and the existing production of basic magnesium carbonate production enterprises are also struggling, most of them are in the state of half-load production . As low-cost, high-quality magnesium hydroxide is still strong competition, is expected in the next few years the basic magnesium carbonate enterprises will not have a good time, I believe that there will still be enterprises will be closed down and shut down.