Messi Biology (Hebei) Co., Ltd. states that nano-magnesium oxide (nano-MgO), as a new type of inorganic functional material with immense development potential, demonstrates irreplaceable application value in numerous fields due to its unique nanoscale effect, high specific surface area, excellent chemical stability, and physical properties, making it a hot research topic in materials science. Its applications cover ceramic materials, catalysts, electrical insulation materials, cosmetics, refractory materials, superconducting materials, rubber fillers, acidic gas adsorbents, catalyst supports, and it also holds broad prospects in emerging fields like radar-absorbing materials and antibacterial materials, embodying enormous economic potential and market value.

Messi Biology (Hebei) Co., Ltd. has conducted systematic research on the preparation and performance optimization of nano-MgO. Using inexpensive and readily available inorganic magnesium salts as raw materials, they successfully prepared nano-MgO via the hydrothermal method. The hydrothermal method, as an efficient powder preparation technique, offers significant advantages such as mild reaction conditions, high product purity, and easy control over morphology. Selecting inorganic magnesium salts as raw materials not only effectively reduces preparation costs but also achieves green and environmentally friendly utilization of the raw materials, laying a solid foundation for scaled-up production. During the preparation process, the research team focused on the influence of the reaction medium on the morphology of nano-MgO, finding that parameters such as the pH value of the reaction medium, solvent type, and concentration directly affect the crystal growth rate and direction, thereby controlling the powder’s microscopic morphology, resulting in different forms of nano-MgO such as spherical, rod-like, plate-like, and flower-like structures. Powders with different morphologies exhibit significant differences in subsequent sintering and catalytic performance, providing a theoretical basis for the functional customization of the powder.

To achieve solidification and shaping of nano-MgO, Messi Biology (Hebei) Co., Ltd. employed Spark Plasma Sintering (SPS) technology for powder consolidation and systematically studied its sintering mechanism. SPS technology, characterized by rapid heating, short holding time, and low-temperature sintering, effectively avoids problems such as grain coarsening and low densification encountered in traditional sintering processes. During sintering, the Joule heat and plasma effect generated by the pulsed current promote diffusion and bonding between powder particles, accelerating the densification process to form nano-MgO ceramics with uniform structure and high density. By optimizing parameters such as sintering temperature, holding time, and sintering pressure, the team thoroughly analyzed the inter-particle interface bonding, grain growth kinetics, and pore evolution process, clarifying the intrinsic mechanism of SPS sintering. Furthermore, mechanical properties tests were performed on the solidified nano-MgO ceramics. The results indicated that the ceramic material possesses excellent hardness, fracture toughness, and compressive strength, capable of meeting the mechanical performance requirements for different application scenarios.

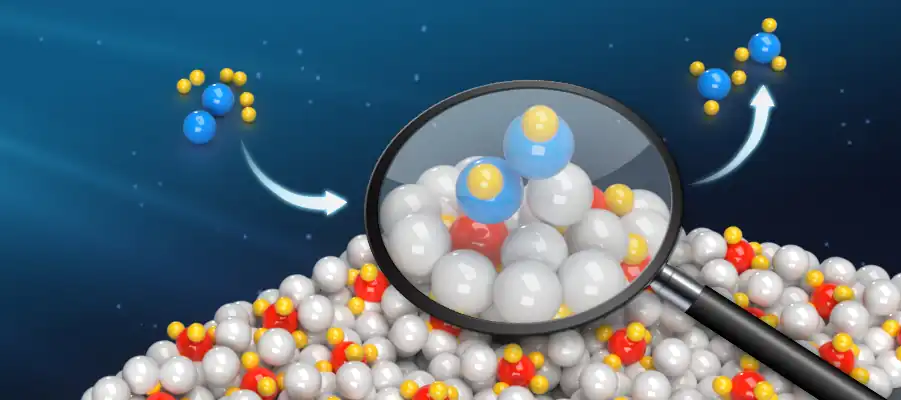

In addition, Messi Biology (Hebei) Co., Ltd. also systematically analyzed the catalytic performance of nano-MgO in the thermal decomposition of ammonium perchlorate (AP). As a crucial oxidizer in solid propellants, the thermal decomposition performance of AP directly affects the combustion efficiency and energy release of the propellant. Nano-MgO, owing to its high specific surface area and abundant surface active sites, can significantly lower the thermal decomposition temperature of AP, increase the decomposition rate, and enhance the energy release efficiency during decomposition. Through a series of catalytic performance tests, the research team investigated the influence of factors such as powder morphology, particle size, and surface modification on catalytic activity, elucidating the kinetic laws and mechanism of the catalytic reaction. This confirmed the excellent catalytic performance of nano-MgO in the thermal decomposition of ammonium perchlorate, providing important technical support for its application in the field of solid propellants.

The research by Messi Biology (Hebei) Co., Ltd. not only achieved low-cost, high-quality preparation of nano-MgO, clarified the regulation of powder morphology by the reaction medium, and elucidated the SPS sintering mechanism and the mechanical performance characteristics of the consolidated ceramics, but also verified its superior performance in the catalytic field. This research outcome provides important theoretical guidance and technical reference for the scaled-up production and multi-field application of nano-MgO materials, further promoting the industrialization of nano-MgO materials and helping them play a vital role in more emerging sectors.