High-purity magnesium oxide generally refers to the purity of more than 98.5% of the magnesium oxide products, with ultra-high melting point, good magnetic conductivity and excellent insulating properties, such as excellent physical properties and specific chemical properties, and its development and industrialization, to support the development of electronics, national defense, aerospace and advanced ceramics and other industries play an extremely critical role. For example:

High-purity magnesium oxide in the ceramic industry as ceramic crucibles, substrates and other raw materials; in the electronics, electrical industry as a magnetic device filler, insulating materials and a variety of carriers; 99% or more high-purity magnesium oxide is the world’s production of oriented silicon-steel sheet is the best chemical raw material. In addition, with high purity magnesium oxide as raw material, can also produce electrofusion magnesium oxide single crystal, high purity electrofusion magnesium oxide, nano magnesium oxide and other special special magnesium oxide series products, these products in the electronics, electrical appliances, optics, instrumentation, metallurgy, national defense and aerospace and other fields have a wide range of applications.

At present, China has been the world’s largest country of magnesium resources, magnesium production, magnesium oxide production of the first country, but it is sad to see that China in the relatively high-end areas of extremely important high-purity magnesium oxide overall strength is still weak, a large share is still dependent on imports.

Resource reserves and production have been the world’s largest for many consecutive years

Magnesium is one of the richest light metal elements on earth, the content in the earth’s crust reaches 2.1%-2.7%, ranked sixth among all elements, is second only to aluminum, iron, calcium in the fourth place of the metal elements.

Magnesium-containing minerals mainly come from dolomite, magnesite, hydromagnesite and olivine. Seawater, natural salt lake water is also rich in magnesium resources.

China is one of the richest countries in the world in magnesium resources, magnesium resources ore type full, wide distribution, the total reserves accounted for 22.5% of the world, ranking first in the world.

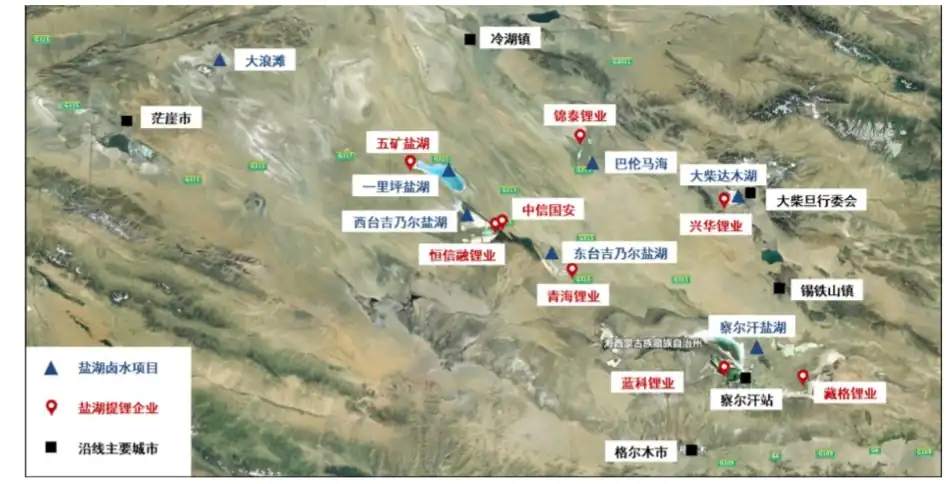

Among them, magnesite reserves ranked first in the world, proven magnesite reserves of 3.4 billion tons, accounting for 28.3% of the world’s total magnesite reserves; China’s magnesium-containing dolomite ore is rich in dolomite resources throughout China’s provinces and districts, especially Shanxi, Ningxia, Henan, Jilin, Qinghai, Guizhou and other provinces and districts, has now been proved to be more than 4 billion tons of reserves; China’s four major salt lakes in the magnesium salt mineral resources in the vision of the reserves of several billions of tons, including , 33 brine lakes, semi-dry salt lakes and dry salt lakes of varying sizes in the Qaidam Basin contain magnesium salt resources with the first place of reserves in the country; the magnesium alloy in China’s sea water reaches 0.13%.

In terms of production, the global magnesium ingot production is relatively stable, with an annual production of about 1 million tons, while China is the main producer of magnesium ingots globally, and the market share of China’s magnesium ingot production from 2016 to the present has been maintained at more than 80%. According to China Nonferrous Metals Industry Association Magnesium Branch data: in 2023 the global raw magnesium production capacity of 1.63 million tons, the global raw magnesium production of 1 million tons, China’s raw magnesium production of 822,400 tons, accounting for 82.24%.

The global magnesium market is very dependent on China, a few years ago, the Financial Times has said: due to China’s production cuts, the magnesium reserves throughout Europe is at a “dangerously low level”. European Aluminum (European Aluminum), Eurometaux, IndustriALL, and other European industry organizations had issued a common statement highlighting that “from September 2021, Chinese magnesium supply will either stop or be significantly reduced, leading to an unprecedented international supply crisis.” The statement said that European governments and the European Commission should “take immediate and urgent action with their Chinese partners to mitigate the severe short-term shortages, as well as the long-term supply implications for the European industry.”

Visible, China in the global magnesium-related industry occupies an extremely important position, whether the total resource reserves or total production is the world’s first.

In addition, China is also the world’s largest producer of magnesium oxide, with total annual production accounting for more than 75% of the world’s total output, but low-end magnesium oxide products occupy a major market share.

High-purity magnesium oxide still need to import from Europe, America and Japan

Compared with high-purity alumina, high-purity quartz sand and other easily 4N (99.99%), 5N (99.999%) purity, purity of 98.5% of magnesium oxide can be called high-purity magnesium oxide, sometimes 98% purity of magnesium oxide is also included in the ranks of the “high purity”, which can be seen in its rare place.

China’s magnesium oxide production originated in the coastal areas of dalian, tianjin and other places, to bitter brine as raw material, using soda ash method of production of magnesium oxide. But the method of energy consumption and high cost, the development is slow. Later, the dolomite carbonization method (known as Patterson method abroad) was successfully developed, due to lower production costs, has been the rapid development of production capacity gradually shifted to Hebei, Shanxi, Hunan, Sichuan and other dolomite reserves in rich areas. However, due to the high calcium content in the magnesium oxide obtained by the dolomite carbonization method, the production of high-purity products is limited.

The current market demand for high purity magnesium oxide is huge, in 2022 China’s high purity magnesium oxide demand for 99,094 tons, since 2015 China’s high purity magnesium oxide demand compound growth rate of 7.87%, the current situation is in short supply. From an economic point of view to analyze, with a purity of 99.5% high purity magnesium oxide, for example, its price is generally about ten times the price of industrial grade magnesium oxide, while the production cost is only double the industrial grade magnesium oxide, with a high added value.

In foreign countries, most of the production of high-purity magnesium oxide and high-purity magnesia production plant are brine (sea) as raw materials, such as the Netherlands Biliton refractories company and Israel Dead Sea magnesite company is a bitter brine and brackish water for magnesium, Japan, the United States, most of the seawater as raw materials, only Greece’s FeiMiShiKo is a natural magnesia as a raw material. The magnesia produced by the above companies is characterized by high MgO content, 98% to 99%; low B2O3 content, below 0.07%.

Japan’s production of seawater magnesium sand purity up to 99.9% in seawater production of high-purity magnesium products technology in the world’s leading position. In addition, Japan due to the rich production of high-quality limestone, so in the Japanese enterprises using dolomite / limestone method of production of some high-purity magnesium oxide content of up to 99.5%.

At this stage, China’s high-purity magnesium oxide is mainly used in the process is simple, high-cost soda ash method and low resource utilization, for the environment to produce a huge threat to the ammonia method, and the production of enterprises are generally smaller, lower production capacity, has not been able to fully meet the needs of China’s metallurgy and other high-end manufacturing industry, had to import high-priced products from Europe, America, Japan and other regions and countries.

Summary

At present, although China’s magnesium resource reserves, magnesium and ordinary magnesium oxide production are high in the world’s first, but in terms of high-purity magnesium oxide in China’s level of development is still weaker than abroad, part of the demand is still dependent on Europe, the United States, Japan and other countries and regions. But what can be seen is that China’s high purity magnesium oxide production level has also made significant progress, the birth of a number of production enterprises with a certain strength, taking into account the current state of supply and demand and the market pattern, in the future there will be a broad space for domestic substitution in waiting for them.