This paper compares the discharge phenomena of two isolation powders with different magnesium oxide contents at 500℃ and 600℃. It is found that the magnesium oxide content in the isolation powder is low, the internal resistance of the battery is small, and the discharge performance is excellent at relatively low temperature; but when working at relatively high temperature, the flow inhibition ability of magnesium oxide on the molten salt electrolyte is weakened, the self-discharge phenomenon of the battery is aggravated, and the working time is shortened.

In order to improve the electrochemical performance of Zn-Ni battery, magnesium oxide is added to the zinc negative electrode active material by physical mixing method, and the effects of different magnesium oxide addition amounts on the charge and discharge characteristics, internal resistance, discharge capacity and cycle life of Zn-Ni battery are compared by constant current charge and discharge test. The experiment shows that adding an appropriate amount of magnesium oxide to the zinc negative electrode of Zn-Ni battery can reduce charge and discharge polarization, reduce the internal resistance in the later stage of the cycle, improve the utilization rate of the negative electrode active material, and extend the battery cycle life. The addition of 1.0%wt magnesium oxide should not be too large.

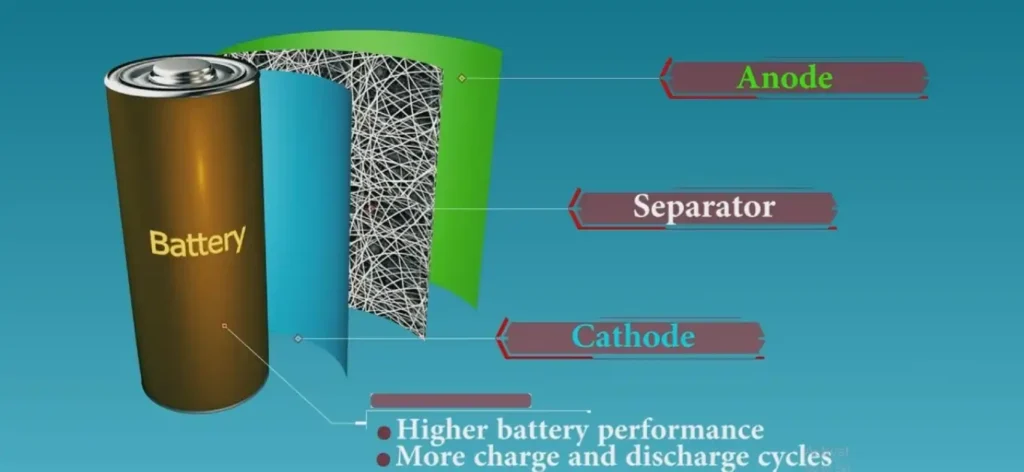

The present invention relates to a method for coating a high-nickel positive electrode material of a lithium-ion battery with magnesium oxide, comprising the following steps:

(1) dissolving magnesium oxide in an acetic acid solution to obtain a colorless transparent solution, and dissolving the magnesium oxide in a 250 ml volumetric flask with anhydrous ethanol after the solution is completely dissolved;

(2) weighing the high-nickel positive electrode material into a beaker, adding ethanol, and stirring under a stirrer;

(3) in the step (3), the mass percentage of magnesium oxide in the positive electrode material of the lithium-ion battery is 0.01-1wt%, and the liquid in the beaker evaporates to almost complete;

(4) continuing to stir until the liquid in the beaker evaporates completely;

(5) drying the product obtained in the above step (4) in a drying oven for 1-4 hours at a temperature of 80°C-110°C;

(6) subjecting the product obtained in the above step (5) to heat treatment for 2-6 hours at a temperature of 500°C-800°C. The present invention has a cheap source of raw materials, a simple process, a short cycle, and improves the performance of the material.