ABSTRACT

The objective of this study was to evaluate the effects of replacing magnesium oxide (MgO) with calcium-magnesium carbonate [CaMg(CO3)2] on ruminal fermentation with or without the addition of sodium bicarbonate (NaHCO3). Eight fermentors of a dual-flow continuous-culture system were distributed in a replicated (2) 4 × 4 Latin square design in a 2 × 2 factorial arrangement of treatments (magnesium sources × NaHCO3). The treatments tested were 0.21% MgO [MgO; dry matter (DM) basis; 144.8 mEq of dietary cation-anion difference (DCAD)]; 0.21% MgO + 0.50% NaHCO3 (MgO+NaHCO3; DM basis; 205.6 mEq of DCAD); 1.00% CaMg(CO3)2 [CaMg(CO3)2; DM basis; 144.8 mEq of DCAD]; and 1.00% CaMg(CO3)2 + 0.50% NaHCO3 [CaMg(CO3)2+NaHCO3; DM basis; 205.6 mEq of DCAD]. Diets were formulated to have a total of 0.28% of Mg (DM basis). The experiment consisted of 40 d, which was divided into 4 periods of 10 d each, where 7 d were used for adaptation and 3 d for sampling to determine pH, volatile fatty acids (VFA), ammonia (NH3-N), lactate, mineral solubility, N metabolism, and nutrient digestibility. The effects of Mg source [MgO vs. CaMg(CO3)2], NaHCO3 (with vs. without), and the interaction were tested with the MIXED procedure of SAS version 9.4 (SAS Institute). There was no Mg source × NaHCO3 interaction in the pH variables and mineral solubility, and Mg sources evaluated did not affect the variables related to ruminal pH and solubility of Mg. On the other hand, the inclusion of NaHCO3 increased the pH daily average, independent of Mg source, which led to a reduced time that pH was below 5.8 and decreased area under the curve. Total VFA and lactate concentration were similar among treatments regardless of NaHCO3 and Mg source; however, the molar proportion of isobutyrate and NH3-N concentration were lower in diets with CaMg(CO3)2 compared with MgO. Moreover, NaHCO3 inclusion increased NH3-N, total daily NH3-N flow, isobutyrate concentration, and acid detergent fiber digestibility. Our results showed that CaMg(CO3)2 leads to a lower NH3-N concentration and isobutyrate proportion. Therefore, because most of the tested variables were not significantly different between MgO and CaMg(CO3)2 when combined or not with NaHCO3, CaMg(CO3)2 can be a viable alternative source to replace MgO in dairy cow diets without affecting mineral solubility, ruminal pH, nutrient digestibility, total VFA, and the main ruminal VFA. Although Mg sources are known to have an alkalizing effect, NaHCO3 inclusion in diets with Mg supplementation allowed an increase in ruminal pH, as well as an increase in isobutyrate and NH3-N flow.

INTRODUCTION

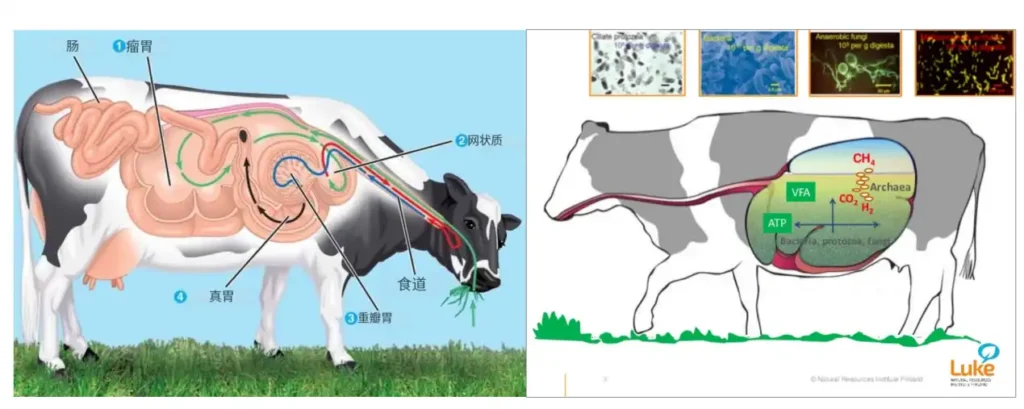

Magnesium is an essential mineral to the metabolism of dairy cows because it is a cofactor for many vital enzymes. The most used magnesium source in dairy cow diets is magnesium oxide (MgO; NRC, 2001; Goff, 2018). Magnesium oxide has been shown to have alkalizing effects in the rumen (Bach et al., 2018) and to increase milk fat synthesis in dairy cows (Erdman et al., 1980).

Because MgO is an expensive Mg source, other sources, such as calcium-magnesium carbonate [CaMg(CO3)2] and calcium-magnesium hydroxide [CaMg(OH)4], have been studied in relation to ruminal fermentation and dairy cow performance as potential alternatives to MgO (May et al., 2009; Leno et al., 2017; Arce-Cordero et al., 2020, 2021). Calcium-magnesium carbonate is a potential source for replacing MgO with no differences in dairy cow performance (Leno et al., 2017) and in vitro ruminal nutrient digestibility (Arce-Cordero et al., 2020).

Magnesium sources also have effects in controlling ruminal pH because of their alkalizing capacity. Teh et al. (1985) observed that dairy cows in early lactation supplemented with 0.8% MgO had a similar pH of cows supplemented with NaHCO3, which was a greater ruminal pH than in cows supplemented with 0.4% of MgO. In addition, Thomas and Emery (1969) observed that cows fed with a roughage-restricted diet, supplemented with 181 g/d of MgO, had a greater ruminal pH than cows fed with 136 g/d; however, they did not observe additional effects of combining MgO supplementation with NaHCO3. On the other hand, Erdman et al. (1982), feeding dairy cows in early postpartum combining 0.8% of MgO and 1% of NaHCO3 supplementation, observed that the association of both components had a greater effect in increasing NDF digestibility than either component individually.

In addition to MgO, other Mg sources have been tested in dairy cow diets, such as calcareous marine. Calcareous marine is similar to CaMg(CO3)2, predominantly constituted by Ca and Mg (Bernard et al., 2014; Cruywagen et al., 2015; Neville et al., 2019). Cruywagen et al. (2015) and Neville et al. (2019) observed that cows supplemented with calcareous marine had a lower time that rumen pH was below 5.5 than control diets.

Although some studies test magnesium sources in dairy cows, the effects of combining CaMg(CO3)2 with sodium bicarbonate (NaHCO3) on ruminal fermentation and nutrient digestibility is still unknown. Therefore, we hypothesized that CaMg(CO3)2 can replace MgO without affecting ruminal pH, VFA concentration, and nutrient digestibility. Moreover, we hypothesized that either Mg source in combination with NaHCO3 would have a similar effect on ruminal fermentation, and NaHCO3 would have the buffer capacity independent of the Mg source provided in the treatments. The objective of this study was to evaluate the effects of replacing MgO with CaMg(CO3)2 when both sources were supplemented with or without NaHCO3, and the effects of NaHCO3 in diets supplemented with Mg sources on ruminal pH, ruminal solubility of Ca and Mg, VFA, nutrient digestibility, and N metabolism.

MATERIALS AND METHODS

Experimental Design and Diets

All animal procedures were approved by the University of Florida’s Institutional Animal Care and Use Committee. Eight fermentors of a dual-flow continuous-culture system were distributed in a replicated 4 × 4 Latin square design in a 2 × 2 factorial arrangement. One factor was the magnesium source as a conventional source (MgO) versus an alternative source [CaMg(CO3)2; MIN-AD, Papillon Agricultural Products]; the other factor was the presence or absence of NaHCO3.

The experimental diets (Table 1) were formulated to provide the same concentration of nutrients and to meet the requirements of lactating Holstein cows with 650 kg of BW, producing 45 kg of milk per day, with 3.5% fat, 3.0% protein, and 4.8% lactose, according to NRC (2001). The treatments tested were MgO (0.21% MgO; DM basis; 144.8 mEq of DCAD); MgO+NaHCO3 (0.21% MgO + 0.5% of NaHCO3, DM basis; 205.6 mEq of DCAD); CaMg(CO3)2 [1% CaMg(CO3)2, DM basis; 144.8 mEq of DCAD]; and CaMg(CO3)2+NaHCO3 [1% CaMg(CO3)2 + 0.5% NaHCO3, DM basis; 205.6 mEq of DCAD].

Table 1. Ingredient and chemical composition of experimental diets

| Ingredient | Treatment1 | |||

|---|---|---|---|---|

| MgO | MgO+NaHCO3 | CaMg(CO3)2 | CaMg(CO3)2+NaHCO3 | |

| Basal diet, % of DM | ||||

| Corn silage | 47.0 | 47.0 | 47.0 | 47.0 |

| Grass hay | 10.0 | 10.0 | 10.0 | 10.0 |

| Ground corn grain | 21.1 | 20.6 | 20.9 | 20.3 |

| Soybean meal | 19.1 | 19.2 | 19.1 | 19.2 |

| White salt | 0.50 | 0.50 | 0.50 | 0.50 |

| Calcium phosphate | 0.55 | 0.55 | 0.55 | 0.55 |

| Trace mineral2 | 0.50 | 0.50 | 0.50 | 0.50 |

| Calcitic limestone | 1.03 | 1.03 | 0.46 | 0.46 |

| Magnesium oxide (MgO) | 0.21 | 0.21 | — | — |

| Calcium-magnesium carbonate [CaMg(CO3)2] | — | — | 1.00 | 1.00 |

| Sodium bicarbonate (NaHCO3) | — | 0.50 | — | 0.50 |

| Chemical composition3 | ||||

| CP | 16.0 | 16.0 | 16.0 | 16.0 |

| Rumen degraded protein | 60.6 | 60.3 | 60.5 | 60.2 |

| Ether extract | 2.97 | 2.95 | 2.96 | 2.94 |

| NDF | 29.6 | 29.6 | 29.6 | 29.6 |

| Starch | 31.9 | 31.5 | 31.8 | 31.3 |

| NEL, Mcal/kg | 1.69 | 1.68 | 1.69 | 1.68 |

| Ca | 0.67 | 0.67 | 0.67 | 0.67 |

| P | 0.37 | 0.37 | 0.37 | 0.37 |

| Mg | 0.28 | 0.28 | 0.28 | 0.28 |

| K | 1.22 | 1.22 | 1.22 | 1.22 |

| DCAD4 | 144.8 | 205.6 | 144.8 | 205.6 |

1, Experimental treatments: MgO (conventional source of Mg); MgO+NaHCO3 (conventional source of Mg plus NaHCO3); CaMg(CO3)2 (alternative source of Mg); and CaMg(CO3)2+NaHCO3 (alternative source of Mg plus NaHCO3).

2, Composition on a DM basis: 99% NaCl, 0.35% Zn, 0.2% Fe, 0.2% Mn, 0.03% Cu, 0.007% I, and 0.005% Co.

3, Expressed as a percentage of DM unless otherwise stated.

4, DCAD: (Na + K) − (Cl + S).

The MgO contained 48.3% Mg and 2.09% Ca (DM basis), and the CaMg(CO3)2 had 12.6% Mg and 21.2% Ca (DM basis). The diets were formulated to 0.28% Mg and 0.67% Ca (DM basis); calcitic limestone was used to reach a uniform concentration of Ca in all diets. The concentrations of Mg and NaHCO3 in the diets were based on literature recommendations for lactating Holstein dairy cows (NRC, 2001; Hu and Murphy, 2005).

The whole-plant corn silage was collected and dried in a forced-air oven (Heratherm, Thermo Scientific) at 60°C for 72 h. Subsequently, corn silage and the other feedstuffs (corn grain, soybean meal, and grass hay) were ground in a Wiley mill (model no. 2; Arthur H. Thomas Co.) to pass a 2-mm screen. Each ingredient was homogenized, and one sample was taken and ground to pass a 1-mm screen to determine the chemical composition.

Dual-Flow Continuous-Culture System

The experiment was carried out in a dual-flow continuous-culture system similar to that developed by Hoover et al. (1976). This system accurately simulated the ruminal fermentation (Brandao and Faciola, 2019; Brandao et al., 2020) due to constant temperature at 39°C, agitation at 100 rpm, and infusion of N2 gas to keep an anaerobic environment. The artificial saliva was formulated according to Weller and Pilgrim (1974), and the infusion rate of 3.0 mL/min of artificial saliva was used to allow liquid and solid flow removal. The saliva was constituted of 1.76 g of NaHPO4, 5 g of NaHCO3, 0.6 g of KCl, 1.6 g of KHCO3, and 0.2 g of urea diluted in 1 L of water. Total passage rate for the system was maintained at 11%/h with liquid removed at 5.5%/h and solid allowed to flow out at a rate of 5.5%/h.

Experimental Period and Feed Management

The experiment consisted of 40 d and was divided into 4 periods of 10 d each (7 d of adaptation and 3 d of sampling). On the first day of each period, rumen content was collected from 2 cannulated lactating Holstein cows 2 h after morning feeding to inoculate the in vitro system. The cannulated dairy cows were previously adapted to a total mixed diet (38% whole-plant corn silage, 19% ground corn, 13% soybean meal, 11% cottonseed, 9% citrus pulp, 8.5% mineral premix, and 1.5% palmitic acid supplement, on DM basis). The rumen content was squeezed through 4 layers of cheesecloth, stored into prewarmed (39°C) thermo bottles (Thermo bottle 3.8 L; Coleman Co. Inc.), and immediately transported to the laboratory. The rumen content from those cows were mixed in the proportion 50:50 (vol/vol), and the mixture was added into prewarmed fermentors (39°C) until overflow into the solid effluent container.

Each fermentor was fed daily with 106 g of diet (DM basis), equally divided into 2 feeding times, one at 0800 and the other at 1800 h, and all the ingredients, including the treatments, were already included in the 106 g. On the first 4 d of each fermentation period, artificial saliva nonenriched with 15N was used. On the fifth day, this saliva was replaced with an 15N-enriched saliva formulated to contain 0.077 g of (15NH4)2SO4 10.2% atom excess (Sigma-Aldrich Co.) per liter until the end of the period. Before the morning feeding on d 5, each fermentor received a pulse dose of 0.1733 g of (15NH4)2SO4. The 15N was used as a marker to estimate ruminal microbial protein synthesis (Calsamiglia et al., 1996).

Samples and Data Collection

Background samples of a homogenized combination of liquid and solid effluents from each fermentor and nonenriched artificial saliva sample were collected on d 5 of each period before the application of the 15N pulse dose to determine DM, ash, and 15N abundance. Samples were stored at −20°C for later processing.

Ruminal pH was measured in the fermenters at 0, 1, 2, 4, 6, and 8 h after morning feeding (0800) on d 8, 9, and 10 with a portable pH meter (Thermo Scientific Orion Star A121, Thermo Fisher Scientific Inc.). At each time point, the pH meter probe was inserted into the fermentors. The pH data were used to calculate daily average pH, percentage of time below pH 5.8 (HrsB5.8) that was calculated using the threshold of 5.8, and area under the pH curve for pH below 5.8 (AUCB5.8). The area was obtained with the trapezoidal rule (Chiou, 1978). Equations for estimating HrsB5.8 and AUCB5.8 are presented below:HrsB5.8 (%) = 100 [time below threshold (h/d)/length of daily pH monitoring time (h)],AUCB5.8 (pH × h) = ∑0–1 h; 1–2 h; 2–4 h; 4–6 h; 6–8 h [(pHa + pHb) (tb − ta)/2],where pHa and pHb represent the measured pH values of each interval between time points at times ta and tb, respectively.

Approximately 10 mL of samples were collected to determine VFA and NH3-N, and 1 mL of samples were collected to determine lactate concentration from inside the fermentors at 0, 1, 2, 4, 6, and 8 h after morning feeding on d 9 and 10 in each fermentation period. Both samples were manually collected from each vessel, at each time point, using a 25-mL serological pipette (Falcon pipette, Corning Inc.) and filtered through 4 layers of cheesecloth. Samples for VFA and NH3-N were acidified with 50% sulfuric acid at the proportion 99:1 (vol/vol, sample:sulfuric acid) and stored at −20°C.

Digesta effluent containers, which consisted of 2 separated containers, one for liquid and another for solid, were immersed in chilled water (around 1°C) on d 9 and 10. The daily contents from the liquid and solid containers were pooled for each fermentor and stored at −20°C. Also, 2 10-mL samples from the pooled effluents (mixed of solid and liquid) were collected and filtered through 4 layers of cheesecloth to determine the solubilization of Mg and Ca and the production of VFA, NH3-N, and lactate by fermentation. Samples to determine VFA and NH3-N concentration were acidified with 50% sulfuric acid at the proportion 99:1 (vol/vol, sample:sulfuric acid) and stored at −20°C.

At the end of d 10 of each period, the entire content from each fermentor was blended for 30 s with 300 mL of 0.9% saline solution, squeezed through 4 layers of cheesecloth, and rinsed with 100 mL of 0.9% saline solution for isolation of bacteria according to Krizsan et al. (2010). The filtrate was centrifuged (Allegra X-15R Centrifuge, Beckman Coulter Life Sciences) at 1,000 × g for 10 min at 4°C to remove the residual particles from the feed. The supernatant was collected and centrifugated in an ultra-speed centrifuge (Sorvall RC-5B Refrigerated Superspeed Centrifuge, DuPont Instruments) at 11,250 × g for 20 min at 4°C to obtain the bacteria pellet. The pellet was resuspended using 200 mL of McDougall’s solution and centrifuged at 16,250 × g for 20 min at 4°C. The bacterial pellet was harvested from the third centrifugation and stored at −20°C.

Background, saliva, bacteria pellet, and digesta samples were subsequently dried in a freeze dryer, and their chemical composition was determined to estimate the microbial protein synthesis and ruminal disappearance of nutrient fractions.

Laboratory Analysis

Rumen fluid samples to determine VFA and NH3-N concentration were centrifuged at 10,000 × g for 15 min at 4°C. Ammonia nitrogen concentration was determined as described by Broderick and Kang (1980) and adapted to a plate reader by using 2 µL of the sample, 100 µL of phenol, and 80 µL of hypochlorite in each well of the microplate. Absorbance was measured in a spectrophotometer (SpectraMax Plus 384 Microplate Reader, Molecular Devices) at 620 nm.

Samples to determine VFA were processed in a second centrifugation step, according to Ruiz-Moreno et al. (2015), where crotonic and metaphosphoric acid solution was added in a 1:5 ratio to the supernatant and frozen overnight. The sample was then centrifuged at 10,000 × g for 15 min at 4°C. The supernatant was recovered, and ethyl acetate was added in a 2:1 ratio to the supernatant, vortexed, and allowed to separate into layers, according to Ruiz-Moreno et al. (2015) with the following modifications. The top layer was transferred to a chromatography vial. The concentration of acetate, propionate, butyrate, isobutyrate, isovalerate, valerate, and caproate was determined by gas chromatography (Agilent 7820A GC, Agilent Technologies) using a flame ionization detector and a capillary column (CP-WAX 58 FFAP 25 m 0.53 mm, Varian CP7767, Varian Analytical Instruments) at 110°C with injector temperature at 200°C and detector at 220°C.

Lactate concentration was determined using a commercial kit (D-Lactic acid / L-Lactic acid kit, R-Biopharm AG). Samples were processed and analyzed according to the instructions provided by the manufacturer. Absorbance was measured in a spectrophotometer (SpectraMax Plus 384 Microplate Reader, Molecular Devices).

Samples to determine Ca and Mg solubility were centrifuged at 18°C and 2,700 × g for 15 min, and the supernatant was transferred to another tube and centrifuged at 20°C and 30,000 × g for 30 min in an ultra-speed centrifuge (Sorvall RC-5B Refrigerated Superspeed Centrifuge, DuPont Instruments). The supernatant was harvested and stored at −20°C. The concentration of soluble Mg and Ca was determined in the effluent samples by inductively coupled plasma mass spectrometry, according to method no. 985.01 (AOAC International, 2000).

Saliva, background, digesta, and bacteria samples were placed into 2-mL microcentrifuge tubes using 2.0-mm zirconia beads and sequentially processed in a homogenizer (Precellys 24, Bertin) at 5,500 × g for 10 s to process the samples for determination of N and 15N percent. The samples were loaded into tin capsules (Elemental microanalysis) and weighed using a microscale (Excellence Plus XP Micro Balance Mettler-Toledo GmbH, Laboratory & Weighing Technologies). To avoid NH3-N contamination during the analysis, 35 µL of K2CO3 solution (10 g/L) was added to the samples and allowed to dry overnight in a forced-air oven at 40°C. The percent 15N in dried samples was determined using a mass spectrometer (IsoPrime 100, IsoPrime), and the results were expressed as the fractional abundance of isotopic fractions (15N/14N).

The DM content was determined at 105°C using an oven according to method no. 930.15 (AOAC, 1990). Ash was determined by combustion at 600°C for 6 h in a furnace, according to method no. 942.05 (AOAC, 1990). Neutral detergent fiber was determined, according to Mertens et al. (2002), using thermostable α-amylase and sodium modified for an Ankom200 Fiber Analyzer (Ankom Technology).

Calculations for N Metabolism and Disappearance of Nutrients

Total N present in digesta effluent corresponds to the N remaining from microbial ruminal fermentation, and it was subdivided into NH3-N flow, dietary N flow, and bacterial N flow. The NAN is a combination of dietary N flow and bacterial N flow.

Flows of NH3-N, NAN, and bacterial N were determined according to Calsamiglia et al. (1996) and Bach and Stern (1999) using the following equations:NH3-N flow (g/d) = mg/dL of effluent NH3-N × (g of total effluent flow/100);NAN flow (g/d) = g of total N in effluent − g of effluent NH3-N;Bacterial N flow (g/d) = (NAN flow × % atom excess of 15N in NAN effluent)/(% atom excess of 15N in bacteria pellet),where % atom excess of 15N in NAN effluent = % atom 15N in NAN effluent sample − % atom 15N in background. In addition, the flow of dietary N and microbial efficiency indicators were determined according to Bach and Stern (1999) as follows:Dietary N flow (g/d) = g of NAN in effluent − g of bacterial N in effluent;Bacterial efficiency = bacterial N flow (g)/OM truly digested (kg);Efficiency of N use = (g of bacterial N/g of available N) × 100.

Ruminal disappearance of the nutrients in the digesta effluent was estimated according to Soder et al. (2013) as follows:% Nutrient disappearance (DM basis) = 100 × [g of nutrient intake − (g of nutrient in effluent − g of nutrient in saliva − g of nutrient in bacteria)]/g of nutrient intake.

Statistical Analysis

Data were analyzed with the MIXED procedure of SAS 9.4 (SAS Institute Inc.) as a replicated 4 × 4 Latin square in a 2 × 2 factorial arrangement. The model included fermentors as the experimental unit; treatments as a fixed effect; and square, period, and fermentor within square as random effects for average daily pH, nutrient disappearance, N metabolism, and daily average concentrations of VFA, Ca, and Mg solubility. For pH, NH3-N, VFA, and lactate kinetics, time was included in the model, and data were analyzed as a repeated measure, and first-order autoregressive was adopted as the covariance structure based on Akaike information criterion. The minimal detectable difference was calculated for all the variables. The effects of Mg source [MgO vs. CaMg(CO3)2], NaHCO3 (presence vs. absence), and the interaction between those factors were analyzed by orthogonal contrasts. Significance was declared at P ≤ 0.05, and tendency was declared at 0.05 < P ≤ 0.10.

RESULTS AND DISCUSSION

Ruminal pH

There was no detectable Mg source × NaHCO3 interaction for ruminal pH, pH variables, or mineral solubility (P > 0.17, Table 2). The absence of detectable differences indicated that NaHCO3 could be used with either MgO or CaMg(CO3)2, and the sources of Mg tested in this experiment would not change the effect of NaHCO3 on ruminal pH. The results also indicated that mineral solubility was independent of NaHCO3 utilization. When looking at individual factors, there was no detectable difference of Mg source in the variables related to ruminal pH (P > 0.31).

Table 2. Effect of magnesium sources with or without NaHCO3 on pH and mineral solubility in a continuous-culture system

| Item1 | Treatment2 | SEM | MDD3 | Contrast (P-value)4 | |||||

|---|---|---|---|---|---|---|---|---|---|

| MgO | MgO+NaHCO3 | CaMg(CO3)2 | CaMg(CO3)2+NaHCO3 | Mg source | NaHCO3 | Interaction | |||

| pH | 5.72 | 5.86 | 5.74 | 5.77 | 0.09 | 0.09 | 0.38 | 0.05 | 0.20 |

| pH-B5.8, % | 66.7 | 45.8 | 61.5 | 53.1 | 10.6 | 13.6 | 0.87 | 0.04 | 0.35 |

| pH-AUC | 56.7 | 58.3 | 56.9 | 57.2 | 0.87 | 0.92 | 0.31 | 0.05 | 0.17 |

| Ca, mg/kg | 131.4 | 96.0 | 80.9 | 91.0 | 37.4 | 44.4 | 0.21 | 0.56 | 0.30 |

| Mg, mg/kg | 229 | 266 | 223 | 242 | 32.0 | 49.2 | 0.54 | 0.25 | 0.69 |

1, pH-B5.8: percentage of time with a pH below 5.8; pH-AUC: area under the curve of pH (pH × h).

2, Experimental treatments: MgO (conventional source of Mg); MgO+NaHCO3 (conventional source of Mg plus NaHCO3); CaMg(CO3)2 (alternative source of Mg); and CaMg(CO3)2+NaHCO3 (alternative source of Mg plus NaHCO3).

3, MDD = minimal detectable difference.

4, Contrasts: Mg source = magnesium oxide vs. calcium-magnesium carbonate; NaHCO3 = presence vs. absence of NaHCO3; interaction = interaction between Mg source and NaHCO3.

Components that can modulate ruminal pH have been tested over the years to mitigate rumen acidosis in high-producing dairy cow diets (Krause and Oetzel, 2006) when substrates are fermented by ruminal microorganisms to VFA and lactate (Van Soest, 1994), consequently leading to a low pH (Owens et al., 1998). Magnesium oxide can be used to aid in the prevention of ruminal pH reduction in dairy cows (Erdman et al., 1982). In the current study, both MgO and CaMg(CO3)2 had similar effects on ruminal pH, which indicated that CaMg(CO3)2 could provide a similar alkalizing effect as MgO. Bach et al. (2018) observed that the supplementation of MgO (0.4% of DM) in diets of dairy cows with an inclusion of 3 kg/d of barley to challenge ruminal pH was able to prevent the reduction of ruminal pH and decrease the time that pH was below 5.8, compared with the control treatment and treatment with NaHCO3 inclusion (0.8% of DM).

Other mineral sources such as calcareous marine have been tested in dairy cow diets that provide minerals and, at the same time, modulate ruminal pH and may affect animal performance (Bernard et al., 2014; Cruywagen et al., 2015; Neville et al., 2019). Neville et al. (2019) evaluated the supplementation of calcareous marine with or without marine MgO versus sodium bicarbonate in mid-lactation dairy cows. Neville et al. (2019) observed that ruminal pH was generally higher, and the time that pH was below or equal to 5.5 was lower in animals supplemented with calcareous marine combined or not with marine MgO than the negative control and sodium bicarbonate. In addition, Cruywagen et al. (2015) observed that calcareous marine had a greater capacity in buffering the rumen than sodium bicarbonate, although sodium bicarbonate already provided a lower time of pH below 5.5 than the control treatment. In our study, we did not evaluate the effect of CaMg(CO3)2 in the rumen against a negative control; however, ruminal fermentation was not affected by CaMg(CO3)2 differently than MgO that is usually associated with alkalizing capacity (Erdman et al., 1982; Bach et al., 2018).

As previously mentioned, nutritionists usually combine NaHCO3 with MgO in high-producing dairy cow diets to improve the control of ruminal pH (Goff, 2018). The justification of using feed additives to control ruminal pH is that those diets are formulated to contain a high concentration of grains to meet energy requirements (Krause and Oetzel, 2006), and this condition favors the occurrence of ruminal acidosis (Owens et al., 1998). In the current study, we observed that NaHCO3 provided support for buffer capacity during ruminal fermentation independent of supplemental Mg source. The inclusion of NaHCO3 increased the average daily pH (P = 0.05, Table 2) and consequently led to a lower percentage of time (P = 0.04) that pH was below 5.8 and decreased the area under pH curve (P = 0.05). Although we did not evaluate the alkalizing capacity of Mg individually, compared with a diet without magnesium, we observed that NaHCO3 was able to play a role as a rumen buffer regardless of which Mg source was provided in the treatments. The results corroborate the observations of Rogers et al. (1982), where adding NaHCO3 to dairy cow diets increased ruminal pH and improved nutrient utilization in the rumen. In addition, Hu and Murphy (2005) observed that ruminal pH of dairy cows fed corn silage as the main source of forage was greater when supplemented with NaHCO3.

Mineral Solubility

The results also indicated that mineral solubility was independent of NaHCO3 supplementation. When looking at individual factors, there were no detectable differences of Mg source in Mg (P = 0.54) and Ca (P = 0.21) solubility in the rumen. Also, there was no detectable difference of buffer in Mg and Ca solubility (P = 0.25; P = 0.56, respectively). The Mg solubility results observed in this study corroborate the results reported by Zyzak et al. (2002), which observed similar solubility for MgO and CaMg(CO3)2 at acidic pH. The similarity in Mg solubility is another relevant point that would suggest that it is possible to replace conventional MgO source with CaMg(CO3)2 when availability and prices are comparable. In addition, Arce-Cordero et al. (2020) also observed that MgO, CaMg(CO3)2, and CaMg(OH)4 had similar mineral solubility in vitro. However, Arce-Cordero et al. (2020) did not evaluate if CaMg(CO3)2 or MgO combined with NaHCO3 would still provide similar mineral solubility independent of the source because the only source that they combined with buffer (sodium sesquicarbonate) was MgO.

In our study, we observed that CaMg(CO3)2 could also be combined with NaHCO3 without affecting mineral solubility. Arce-Cordero et al. (2021) also evaluated the replacement of MgO with a blend of CaMg(CO3)2 and CaMg(OH)4, and they observed that MgO had a greater Mg solubility compared with the blend that is possibly related to CaMg(OH)4 solubility or other factors such as particle size and Mg source. According to Beede (2017), mineral solubility may be affected by mineral sources; however, the calcination process, particle size, and contamination with other minerals can have a strong effect on the solubility of calcined sources such as MgO. These factors affecting solubility may explain the lack of consistency in previous studies with the same mineral source. In addition, Zyzak et al. (2002) observed that apparent absorption and retention of Mg in sheep did not differ between CaMg(CO3)2 and MgO, which indicates that not only the solubility was not affected by those sources, but also the metabolism was not different between sources. Therefore, in the current study, mineral solubility was similar between MgO and CaMg(CO3)2. Although Bernard et al. (2014) did not evaluate ruminal mineral solubility, they observed that early-lactation dairy cows supplemented with calcareous marine (a source that also provides Ca and Mg) against sodium bicarbonate and a negative control did not have differences in the blood mineral concentration. Although there was no statistical difference, we speculate that Ca solubility was numerical greater in the diets formulated with MgO because of the greater Ca solubility from calcitic limestone, which was used to adjust the Ca concentration in the diets, compared with CaMg(CO3)2.

Volatility Fatty Acids, Lactate, and N Metabolism

There was no treatment × time interaction for the repeated measures of VFA, lactate, and NH3-N (data not shown). This indicated that, although there was an effect of time for those variables, the variation pattern was similar among the treatments over time. The effects of Mg source × NaHCO3 interaction and individual effects of Mg source and NaHCO3 inclusion on VFA molar proportion and N metabolism parameters are presented in Table 3, Table 4, respectively. There was no Mg source × NaHCO3 interaction for VFA proportion (P > 0.13), total VFA concentration (P = 0.14), or lactate concentration (P = 0.70). Also, the total VFA and lactate concentration was similar between Mg sources (P = 0.58; 0.17), and NaHCO3 inclusion (P = 0.85; 0.32); however, the molar proportion of isobutyrate was lower in diets with CaMg(CO3)2 compared with MgO (P = 0.03).

Table 3. Effect of magnesium sources with or without NaHCO3 on the 24-h pool VFA proportion in a continuous-culture system

| Item | Treatment1 | SEM | MDD2 | Contrast (P-value3) | |||||

|---|---|---|---|---|---|---|---|---|---|

| MgO | MgO+NaHCO3 | CaMg(CO3)2 | CaMg(CO3)2+NaHCO3 | Mg source | NaHCO3 | Interaction | |||

| Total VFA, mM | 90.6 | 889 | 88.6 | 89.9 | 1.44 | 1.98 | 0.58 | 0.85 | 0.14 |

| VFA, % of total VFA | |||||||||

| Acetate | 47.9 | 49.2 | 48.8 | 48.5 | 0.95 | 1.17 | 0.92 | 0.37 | 0.17 |

| Propionate | 31.3 | 27.5 | 30.4 | 30.5 | 2.61 | 2.56 | 0.41 | 0.16 | 0.13 |

| Butyrate | 13.8 | 16.2 | 13.8 | 13.9 | 1.53 | 1.67 | 0.15 | 0.14 | 0.17 |

| Valerate | 3.55 | 3.05 | 3.50 | 3.48 | 0.29 | 0.36 | 0.29 | 0.14 | 0.18 |

| Isobutyrate | 0.604 | 0.704 | 0.554 | 0.599 | 0.06 | 0.07 | 0.03 | 0.04 | 0.41 |

| Iso-valerate | 1.98 | 2.35 | 2.16 | 2.16 | 0.21 | 0.25 | 0.95 | 0.14 | 0.15 |

| Caproic | 0.832 | 0.948 | 0.874 | 0.907 | 0.18 | 0.23 | 0.99 | 0.51 | 0.71 |

| Acetate:propionate | 1.57 | 1.88 | 1.66 | 1.67 | 0.17 | 0.21 | 0.59 | 0.13 | 0.14 |

| Lactate, mM | 0.197 | 0.182 | 0.177 | 0.171 | 0.02 | 0.02 | 0.17 | 0.32 | 0.70 |

1,Experimental treatments: MgO (conventional source of Mg); MgO+NaHCO3 (conventional source of Mg plus NaHCO3); CaMg(CO3)2 (alternative source of Mg); and CaMg(CO3)2+NaHCO3 (alternative source of Mg plus NaHCO3).

2, MDD = minimal detectable difference.

3, Contrasts: Mg source = MgO vs. calcium-magnesium carbonate; NaHCO3 = presence vs. absence of NaHCO3; interaction = interaction between Mg source and NaHCO3.

Table 4. Effect of magnesium sources with or without NaHCO3 on N metabolism in a dual-flow continuous-culture system

| Item | Treatment1 | SEM | MDD2 | Contrast (P-value)3 | |||||

|---|---|---|---|---|---|---|---|---|---|

| MgO | MgO+NaHCO3 | CaMg(CO3)2 | CaMg(CO3)2+NaHCO3 | Mg source | NaHCO3 | Interaction | |||

| NH3N, mg/dL | 3.72 | 4.67 | 2.18 | 3.31 | 0.61 | 0.80 | <0.01 | 0.01 | 0.82 |

| N flows, g/d | |||||||||

| Total N4 | 2.75 | 2.71 | 2.68 | 2.74 | 0.08 | 0.13 | 0.68 | 0.90 | 0.39 |

| NH3-N5 | 0.15 | 0.19 | 0.09 | 0.13 | 0.03 | 0.03 | <0.01 | 0.02 | 0.82 |

| NAN6 | 2.60 | 2.52 | 2.59 | 2.6 | 0.08 | 0.12 | 0.57 | 0.57 | 0.41 |

| Bacteria N7 | 1.20 | 1.16 | 1.16 | 1.18 | 0.06 | 0.09 | 0.78 | 0.87 | 0.51 |

| Dietary N8 | 1.40 | 1.36 | 1.43 | 1.42 | 0.05 | 0.09 | 0.27 | 0.52 | 0.64 |

| ENU9 | 46.0 | 42.7 | 42.5 | 43.4 | 2.39 | 3.47 | 0.41 | 0.48 | 0.24 |

| Bact. efficiency10 | 21.4 | 20.2 | 20.5 | 20.5 | 0.99 | 1.79 | 0.77 | 0.52 | 0.52 |

| RDP-N supply11 | 1.72 | 1.88 | 1.80 | 1.81 | 0.05 | 0.09 | 0.85 | 0.06 | 0.10 |

| RUP-N supply11 | 1.40 | 1.36 | 1.43 | 1.42 | 0.05 | 0.09 | 0.27 | 0.52 | 0.64 |

1, Experimental treatments: MgO (conventional source of Mg); MgO+NaHCO3 (conventional source of Mg plus NaHCO3); CaMg(CO3)2 (alternative source of Mg); and CaMg(CO3)2+NaHCO3 (alternative source of Mg plus NaHCO3).

2, MDD = minimal detectable difference.

3, Contrasts: Mg source = MgO vs. calcium-magnesium carbonate; NaHCO3 = presence vs. absence of NaHCO3; interaction = interaction between Mg source and NaHCO3.

4, Total N = NH3-N + NAN (Bach and Stern, 1999).

5, NH3-N = (ammonia N) = effluent NH3-N (mg/dL)/1,000 × [total effluent flow (g)/100].

6, NAN flow (g/d) = total N − NH3-N.

7, Bacteria N flow = (NAN flow × % atom excess of 15 N in NAN effluent)/(% atom excess of 15N in bacteria pellet) (Calsamiglia et al., 1996).

8, Dietary N flow (g/d) = NAN − bacterial N.

9, ENU (efficiency of N use) = (g of bacterial N/g of available N) × 100 (Bach and Stern, 1999).

10, Bacterial efficiency = g of bacterial N/kg of OM truly digested (Calsamiglia et al., 1996).

11, N supply = g/d.

Isobutyrate is a branched-chain VFA associated with AA degradation in the rumen (Dehority et al., 1958). The difference in isobutyrate molar proportion was associated with NH3-N concentration, which was also lower in the diets with CaMg(CO3)2 supplementation (P < 0.01, Table 4), indicating a possible effect on protein degradation. The reduction in NH3-N concentration also led to a reduction in the total flow of NH3-N (P < 0.01).

On the other hand, NaHCO3 inclusion evaluated individually increased NH3-N (P = 0.01), leading to an increase in the total daily NH3-N flow (P = 0.02). Lana et al. (1998) observed a correlation between ruminal pH and deamination, and the increase in ruminal pH could have favored deamination and consequently increased NH3-N concentration when NaHCO3 was included in the diets. This increased deamination may explain the increase in isobutyrate molar proportion (P = 0.04) because this VFA comes from valine metabolism during rumen fermentation (Dehority et al., 1958). Future investigations are required to better understand the mechanism related to MgO that affects NH3-N concentration and, consequently, isobutyrate molar proportion. A tendency for Mg source × NaHCO3 interaction was observed in RDP concentration (P = 0.10), in which the treatment with MgO plus NaHCO3 had a greater RDP than the treatment with just MgO supplementation; however, CP digestibility was similar between treatments (P > 0.19). There was no Mg source × NaHCO3 interaction, neither for the main effect of Mg source nor NaHCO3 inclusion on any other variables related to N metabolism (P > 0.39, P = 0.27, P = 0.48, respectively). This indicated that both MgO and CaMg(CO3)2, at the tested concentrations, had similar effects on N utilization.

There was no effect of NaHCO3 on this acetate:propionate ratio in the current study where all the diets had Mg supplementation (P = 0.13). Moreover, the other VFA proportions were not affected by Mg source or NaHCO3 inclusion (P > 0.15; 0.13), and neither was the ratio of acetate:propionate affected by Mg source (P = 0.59).

Dry Matter and Nutrient Digestibility

There was no Mg source × NaHCO3 interaction for DM and nutrient digestibility (Table 5; P > 0.25). Also, when looking at individual factors, there was no detectable difference between Mg source or NaHCO3 on DM and nutrient digestibility (P > 0.11 and 0.13, respectively). Different than that observed in the present study, Arce-Cordero et al. (2021) observed an interaction Mg source × NaHCO3 in which the buffer increased the CP digestibility only when the diet was supplemented with MgO. Although NaHCO3 inclusion did not affect NDF digestibility in the present study, the literature reports the opposite when buffers are added to the diets with Mg supplementation. Rogers et al. (1982) observed that adding 2% NaHCO3 (DM basis) in dairy cow diets increased fiber digestibility. Also, an increase in fiber digestibility was observed by Erdman et al. (1980) in diets with 1% NaHCO3 inclusion compared with control treatment. In addition, Arce-Cordero et al. (2021) also did not observe effects of Mg sources in DM and NDF when using a dual-flow continuous-culture system; however, they observed a buffer effect on NDF digestibility.

Table 5. Effect of magnesium sources with or without NaHCO3 on DM and nutrient digestibility in a continuous-culture system

| Digestibility,1 % | Treatment2 | SEM | MDD3 | Contrast (P-value)4 | |||||

|---|---|---|---|---|---|---|---|---|---|

| MgO | MgO+NaHCO3 | CaMg(CO3)2 | CaMg(CO3)2+NaHCO3 | Mg source | NaHCO3 | Interaction | |||

| DM | 55.6 | 56.4 | 55.2 | 56.0 | 1.11 | 2.07 | 0.66 | 0.41 | 0.97 |

| OM | 57.8 | 58.9 | 58.1 | 59.2 | 1.22 | 2.17 | 0.75 | 0.32 | 0.98 |

| NDF | 44.9 | 47.6 | 41.9 | 44.8 | 2.38 | 3.12 | 0.11 | 0.13 | 0.94 |

| CP | 46.3 | 50.2 | 47.4 | 47.7 | 1.98 | 3.18 | 0.68 | 0.19 | 0.25 |

1, True digestibility for DM, OM, and CP; apparent digestibility: NDF.

2, Experimental treatments: MgO (conventional source of Mg); MgO+NaHCO3 (conventional source of Mg plus NaHCO3); CaMg(CO3)2 (alternative source of Mg); and CaMg(CO3)2+NaHCO3 (alternative source of Mg plus NaHCO3).

3, MDD = minimal detectable difference.

4, Contrasts: Mg source = MgO vs. calcium-magnesium carbonate; NaHCO3 = presence vs. absence of NaHCO3; interaction = interaction between Mg source and NaHCO3.

CONCLUSIONS

We found that CaMg(CO3)2 reduced NH3-N concentration and isobutyrate and had no differences in regards to digestibility and ruminal fermentation when compared with MgO. This allows for the use of CaMg(CO3)2 as a feasible alternative source of Mg in dairy cow diets without affecting mineral solubility, ruminal pH, and nutrient digestibility. In addition, combining CaMg(CO3)2 with NaHCO3 can control ruminal pH and improve N metabolism. Although Mg sources are known to have an alkalizing effect, NaHCO3 inclusion in diets with Mg supplementation increased ruminal pH, as well as isobutyrate and NH3-N flow.