Magnesium Carbonate (MgCO3) is a widely used inorganic magnesium salt material. Based on variations in purity, physicochemical indicators, production processes, and application scenarios, it can be categorized into different specifications. Products with different specifications show significant differences in purity control, impurity content, particle size distribution, and application fields, directly determining their value and suitability for various industries.

I. Production Process Differences: Fine Purification vs. Conventional Preparation

The production process is the root cause of the differences, dictating the product’s fundamental quality.

- Industrial Grade Magnesium Carbonate is typically prepared from natural minerals like magnesite and dolomite, or industrial MgSO4 (magnesium sulfate) and MgCl2 (magnesium chloride), using conventional processes such as the carbonation method or double decomposition method. The production flow is relatively simple, without the need for complex purification steps, only requiring the satisfaction of basic reaction conditions. For example, in the carbonation method, MgO (magnesium oxide) suspension is carbonized with CO2 , and the finished product is obtained after filtration, drying, and crushing. The entire process has low requirements for raw material purity and the reaction environment, resulting in relatively low production costs suitable for large-scale industrial mass production.

- Electronic Grade Magnesium Carbonate production requires multiple fine purification steps in addition to the standard preparation process, with stringent requirements for raw materials and the production environment. High-purity industrial magnesium salts or brine from salt lakes must be used as raw materials to avoid heavy metal and alkali metal impurities found in natural minerals. Processes such as gradient complexation purification, membrane filtration separation, and vacuum drying are introduced during production to remove trace impurities like Iron ( Fe ), Lead ( Pb ), Arsenic ( As ), Sodium ( Na ), and Potassium ( K ) from the raw materials. Some high-end electronic grade products also require gas-flow classification technology to precisely control particle size distribution, ensuring product performance uniformity, which results in a longer production cycle and higher cost.

II. Core Physicochemical Indicator Differences: Strict Standards vs. Basic Compliance

Physicochemical indicators are the core basis for distinguishing the two, with stark differences, especially in purity and impurity content control.

- Purity Requirements

- Industrial Grade: Purity is typically between 95%–98%, with some products being as low as 90%. It only needs to meet the basic needs of industrial production, with no strict limits on the presence of small amounts of impurities.

- Electronic Grade: Purity requirements are extremely high. Mainstream products must reach 99.5% or higher, and high-end semiconductor-grade products even reach 99.9%–99.99%, with impurity content controlled at the ppm (parts per million) level.

- Impurity Content Control

- Industrial Grade: No strict limits on impurities such as Fe, Pb , As , and Na . For example, Fe content may be allowed below 0.1%, and Pb content may be relaxed to 0.005%, fully satisfying the requirements for applications like rubber fillers, paints, and inks.

- Electronic Grade: Impurity limits are extremely strict: heavy metal impurities like

Fe, Copper (Cu), and Nickel (Ni) must be below 10ppm; toxic and harmful impurities like Pb and As must be below 5ppm; and alkali metal impurities like Na and K must be below 20ppm. If these impurities exceed the limits, they can severely affect the insulation performance, conductivity, and stability of electronic components, thus requiring strict control.

- Particle Size and Morphology

- Industrial Grade: Particle size distribution is relatively wide, typically ranging from a few micrometers to tens of micrometers, with mostly irregular particle shapes. Precise control is not necessary, as it only needs to satisfy basic functions like filling and reinforcement.

- Electronic Grade: Requires narrow and uniform particle size distribution. The size can be precisely controlled between 1–5 micrometers, depending on the application scenario. Uniform particle size and regular morphology ensure good dispersibility in electronic pastes, ceramic sintering, and other processes, preventing agglomeration and thereby enhancing the performance stability of electronic components.

III. Application Field Differences: High-end Electronic Manufacturing vs. Traditional Industrial Fields

The differences in physicochemical indicators directly determine their distinct application scenarios.

- Industrial Grade Magnesium Carbonate applications are concentrated in traditional industrial and civil fields: used as a filler in the rubber industry to enhance the hardness and wear resistance of rubber products; as a white pigment and extender pigment in the paint industry; and also in papermaking, construction materials, food additives, etc., where it serves basic functions like filling, reinforcement, and nutritional fortification.

- Electronic Grade Magnesium Carbonate focuses on the high-end electronic manufacturing sector, serving as a critical raw material for the electronic information industry:

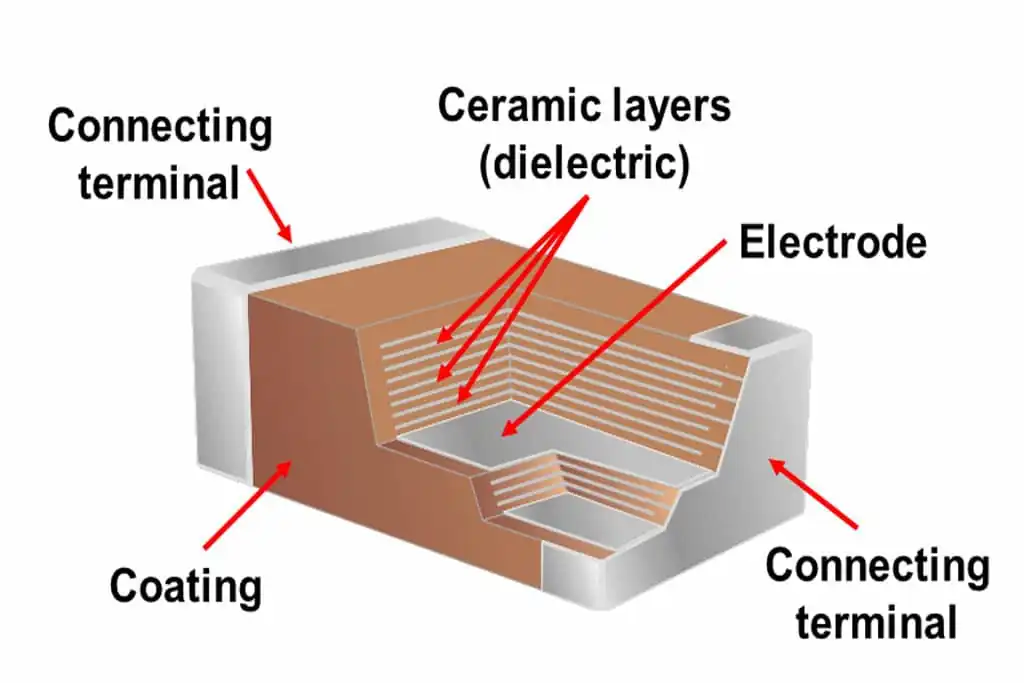

- Sintering Aid: Used as a sintering aid for electronic ceramics, producing components like MLCCs (Multilayer Ceramic Capacitors) and piezoelectric ceramics. It lowers the ceramic sintering temperature and improves the ceramic’s density and dielectric properties.

- Semiconductor Encapsulation: Used as an additive in semiconductor encapsulation materials (e.g., in the preparation of encapsulation glues) to enhance the material’s heat resistance, insulation, and anti-aging performance, ensuring the stable operation of semiconductor chips.

- Electronic Pastes: Used in the preparation of electronic pastes (e.g., conductive pastes, resistive pastes). Uniform particle size ensures the paste’s printability and conductivity.

- Lithium Battery Modification: Also used for modifying cathode materials for lithium batteries, improving the cathode material’s cycle life and charge-discharge performance.

IV. Quality Control and Certification Differences: Full-Process Testing vs. Basic Inspection

The level of sophistication of the quality control system is a crucial support for the product’s quality assurance.

- Industrial Grade Magnesium Carbonate quality inspection is only performed on basic indicators such as main content, moisture, and sieve residue. Testing methods are relatively simple, and there is no need for special industry certification. The product can be sold as long as it meets national general industrial standards.

- Electronic Grade Magnesium Carbonate quality control spans the entire production process, from raw material inspection upon arrival and real-time monitoring during production to full-item testing of the finished product before shipment. High-precision testing instruments are used throughout, and some high-end products must also meet the stringent standards of the semiconductor industry, ensuring compliance with the application requirements of the electronic information industry.

In summary, the difference between electronic grade and industrial grade magnesium carbonate is not merely one of “purity level,” but a comprehensive distinction spanning the production process to the application scenario. Standard magnesium carbonate serves traditional industries with high cost-effectiveness, while electronic grade magnesium carbonate, with its stringent quality standards, has become a key material supporting the high-quality development of the electronic information industry.