Magnesium oxide, as a catalyst or catalyst support, exhibits excellent performance in various catalytic reactions. However, its catalytic performance is affected by several factors, and the following are the key factors that mainly affect the performance of magnesium oxide catalysts:

1. Preparation method of magnesium oxide

Magnesium oxide calcined at high temperature has high crystallinity and thermal stability, but has a small specific surface area.

Magnesium oxide prepared by precipitation or hydrothermal method has a large specific surface area, which is conducive to metal support and catalytic reactions.

2. Acid-base characteristics of magnesium oxide

The alkalinity of magnesium oxide affects the selectivity and activity of the catalyst and can be regulated by doping (such as La, Ce, Zr).

Excessively alkaline may lead to increased side reactions, such as excessive alkalinity may trigger carbonylation or cleavage reactions.

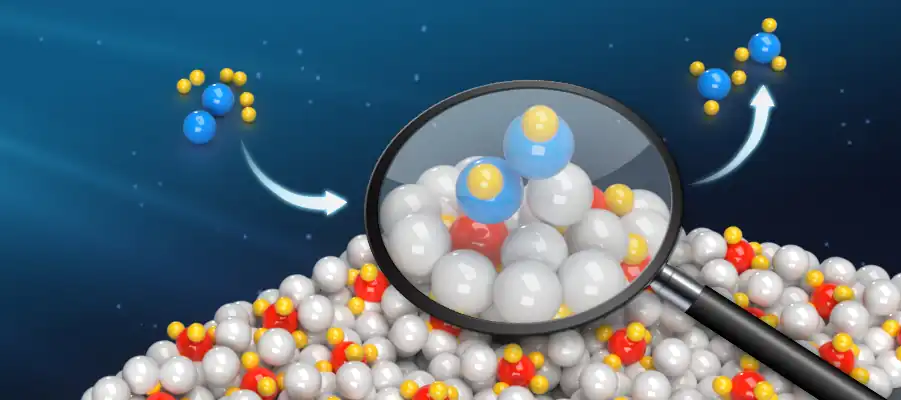

3. Types and dispersion of load metals

The higher the dispersion of the loaded metal, the higher the activity. Magnesium oxide acts as a support to prevent metal agglomeration and improve catalytic life.

The selectivity of the supported metal affects the distribution of hydrogenation products, for example, Ni/MgO is more suitable for olefin hydrogenation, while Ru/MgO is suitable for aromatic hydrocarbon hydrogenation.

4. Reaction conditions (temperature, pressure, H₂/substrate ratio, etc.)

Low temperatures are conducive to selective hydrogenation, while high temperatures may lead to excessive hydrogenation or by-product generation.

Appropriate adjustment of the H₂/substrate ratio can control the degree of hydrogenation. For example, when alkynes are selectively hydrogenated, an appropriate amount of H₂ can improve ethylene selectivity.