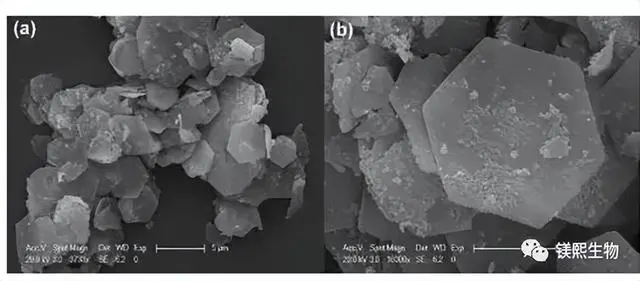

Hexagonal plate magnesium hydroxide (Mg(OH)₂) is an inorganic, environmentally friendly flame retardant. Due to its high thermal stability, smoke suppression capabilities, and halogen-free environmental protection characteristics, it is widely used in flame retardant systems for polymer materials such as rubber and plastics. Its hexagonal plate morphology exhibits significant advantages in improving flame retardant performance and enhancing the mechanical properties of composite materials.

1. Basic Flame Retardant Principle

Hexagonal plate magnesium hydroxide (Mg(OH)₂) is a typical physical inorganic flame retardant. Its main flame retardant mechanisms include: ① Endothermic decomposition at high temperatures, which reduces the surface temperature of the material; ② Decomposition generates water vapor, which dilutes combustible gases; ③ The generated magnesium oxide forms a dense protective layer on the material surface, which isolates heat and oxygen. These processes collectively inhibit combustion and smoke release.

2. Structural Advantages of Hexagonal Plate Morphology

Compared with traditional granular Mg(OH)₂, the hexagonal plate morphology has a larger specific surface area and two-dimensional structure, which allows it to be better distributed within the polymer material and form an effective barrier layer. This “lamellar barrier” effect can extend the diffusion path of heat and decomposition gases, improving flame retardant efficiency.

3. Flame Retardant Effect on Rubber

In elastomers such as natural rubber and styrene-butadiene rubber, hexagonal plate magnesium hydroxide, as an additive flame retardant, can significantly inhibit flame spread, increase the oxygen index, and reduce the heat release rate. At the same time, it can also improve the dimensional stability of rubber at high temperatures, helping to extend the fire resistance time of rubber products.

4. Flame Retardant Effect on Plastics

Adding hexagonal plate Mg(OH)₂ to thermoplastics such as polyethylene (PE), polypropylene (PP), and ethylene-vinyl acetate copolymer (EVA) can effectively improve their flame retardant grade, such as reaching UL-94 V-0 level, while also having the advantage of low smoke and non-toxicity. Due to its high decomposition temperature, it is suitable for various thermoplastic processing techniques.

5. Synergistic Effect Enhances Flame Retardant Effect

Hexagonal plate Mg(OH)₂ can be used in combination with phosphorus-based flame retardants, intumescent flame retardants, organic silicon, etc. Through the dual action mechanism of the condensed phase and the gas phase, the density and thermal insulation performance of the carbon layer structure are improved, thereby significantly enhancing the overall flame retardant effect.

6. Surface Modification Improves Compatibility

By modifying the surface of hexagonal plate Mg(OH)₂ with coupling agents (such as silane and stearic acid), its dispersibility and interfacial bonding performance in the polymer matrix can be significantly improved, reducing agglomeration and improving the mechanical properties of the material, avoiding the problem of “adding a lot but having poor performance.”

7. Synergistic Optimization of Mechanical Properties

Thanks to the physical reinforcing effect of the flaky structure, the reasonable addition of hexagonal plate Mg(OH)₂ not only does not weaken the toughness and tensile strength of rubber and plastic materials, but also enhances their tear strength, hardness, and other mechanical properties, making it particularly suitable for engineering plastics that require both flame retardancy and structural strength.

8. Good Processing Adaptability

Hexagonal plate Mg(OH)₂ performs well in conventional extrusion, injection molding, compression molding, and other processes. It has high thermal stability, is not easy to decompose, and does not volatilize harmful substances. It is suitable for producing flame retardant products such as wire and cable sheaths, floors, appliance housings, and automotive interiors.