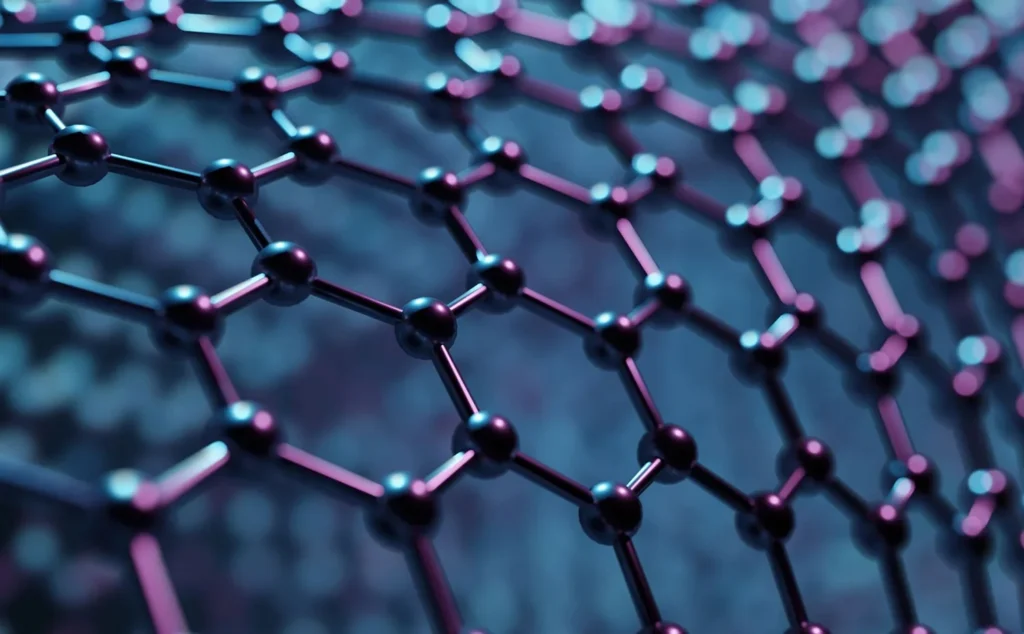

Messi Biology states that graphene, renowned as the “King of New Materials,” consistently faces a critical challenge in its large-scale production: deacidification and purification. The advent of magnesium oxide provides an ideal solution for graphene deacidification. As an alkaline oxide, it undergoes a hydrolysis reaction in aqueous solution to generate magnesium hydroxide colloid. This colloid not only effectively neutralizes residual sulfuric acid through acid-base neutralization, stably adjusting the system’s pH value to a neutral range, but also leverages the high specific surface area of the colloidal particles to form an “adsorption-bridging” effect. This effect causes the tiny suspended particles in graphite oxide to rapidly aggregate into large flocs, achieving efficient sedimentation and separation.

This process demonstrates three core advantages:

Firstly, outstanding environmental performance. Magnesium oxide itself is an inorganic material free of volatile harmful substances. The reaction product, magnesium hydroxide, can be recovered through subsequent processing, preventing secondary pollution.

Secondly, significant efficiency. Compared to traditional methods, magnesium oxide flocculation can reduce deacidification time by over 40%. Additionally, the rapid settling speed of the flocs facilitates continuous industrial production.

Thirdly, strong compatibility. It does not damage the layered structure of graphene. Instead, it protects its surface active functional groups through gentle pH adjustment, laying the foundation for subsequent reduction processes. This “deacidification + flocculation + material protection” tripartite characteristic makes magnesium oxide an ideal auxiliary material for graphene preparation.

Messi Biology’s “Hardcore Strength”: The Benchmark for Localized High-End Magnesium Oxide Production

In the field of magnesium oxide for graphene deacidification, Hebei Messi Biology Co., Ltd.’s products stand out with their full-chain advantages, becoming a core force in replacing imported high-end products. Their product advantages precisely match the stringent requirements of graphene preparation, primarily reflected in three dimensions:

Extreme Purity and Stability: Graphene deacidification is extremely sensitive to impurities. Messi Biology’s electronic-grade magnesium oxide boasts a purity of up to 99.9%, which is 0.3 percentage points higher than comparable international products. Heavy metal residues are controlled below 5 ppm, significantly lower than the EU’s limit of 15 ppm. This high purity ensures that no additional impurities are introduced during the deacidification process, guaranteeing that the electrical performance of the graphene product remains unaffected.

Precise and Controllable Physical Properties: Flocculation effectiveness is directly related to the particle size distribution and activity of magnesium oxide. Utilizing German-imported intelligent production lines, Messi Biology stably controls the product’s D50 value within the 0.8μm±0.05 range, achieving superior dispersibility compared to international brands. The uniform particle size distribution enables magnesium oxide to quickly form stable colloids in an aqueous solution, increasing floc settling speed by 30% compared to ordinary magnesium oxide. Concurrently, its high activity characteristic (activity index 30% higher than the industry standard) reduces the amount of agent required, significantly enhancing the production efficiency of the graphene deacidification process.

Full-Chain Assurance and Customized Services: To address the personalized needs of the graphene industry, the company has established a dedicated laboratory to provide customized solutions. They can optimize magnesium oxide’s activity, particle size, and other indicators based on the specific process parameters of different enterprises. Furthermore, their “72-hour nationwide direct delivery” intelligent warehousing system resolves the pain point of long lead times for imported products (over 90 days), ensuring production continuity. Additionally, the product has passed triple international certifications (FDA, REACH, ROHS), fully meeting the export compliance requirements for high-end graphene.

As graphene’s applications continue to deepen in fields such as electronic devices, energy storage materials, and composite materials, the demand for magnesium oxide used in deacidification will continue to grow. Hebei Messi Biology Co., Ltd.’s technological breakthroughs not only fill a domestic market gap for high-end magnesium oxide but also ensure the security of the industrial chain through localized substitution. In the future, with the further development of magnesium oxide technology, its application in graphene preparation will become even more widespread, injecting continuous impetus into the innovative development of the new materials industry.