Messi Biology states that when a vehicle traverses high-temperature road surfaces, the engine compartment temperature can exceed 120°C. Similarly, the lithium batteries in New Energy Vehicles (NEVs) require precise thermal control to prevent thermal runaway. In these scenarios, the accurate monitoring provided by temperature sensors is vital, and the core material supporting the stable operation of these sensors is the seemingly ordinary Magnesium Oxide (MgO). This multifunctional inorganic material has become a key pillar of automotive temperature sensing technology due to its unique properties.

Dual Empowerment: Electrical Insulation and Thermal Conductivity

The core advantage of Magnesium Oxide lies in its dual capability of providing electrical insulation and thermal conductivity. The electrode wires in automotive temperature sensors must be isolated from electrical currents while rapidly conducting heat. While traditional organic insulation materials are prone to aging and failure under high-heat conditions, MgO boasts a melting point of up to 2800°C and maintains stability across an extreme temperature range of -50°C to 1200°C. It is typically processed into powder or sintered ceramic bodies and filled between the sensor’s metal sheath and the sensitive element. This not only prevents the risk of electrical leakage but also transfers heat rapidly to the measuring end, significantly shortening response times—some armored sensors can achieve a response speed within 10 seconds.

Acting as a “Sensitivity Regulator” for Enhanced Precision

MgO plays the role of a “sensitivity regulator” in improving sensing accuracy. In ultra-fine continuous thermocouples, MgO is a core component; its content directly affects the material’s temperature coefficient of resistance. An appropriate increase in MgO can significantly enhance the sensor’s sensitivity to temperature changes. These sensors, with diameters of only 0.5–1 mm and minimum bending radii of 1–10 mm, can be tightly wrapped around the surface of lithium batteries to achieve comprehensive temperature monitoring with a precision controlled within ±5°C, providing reliable data support for battery thermal management systems. Furthermore, composite ceramics formed by MgO with alumina or iron oxide reduce reactions with the thermocouple wires, preventing precision drift after long-term use.

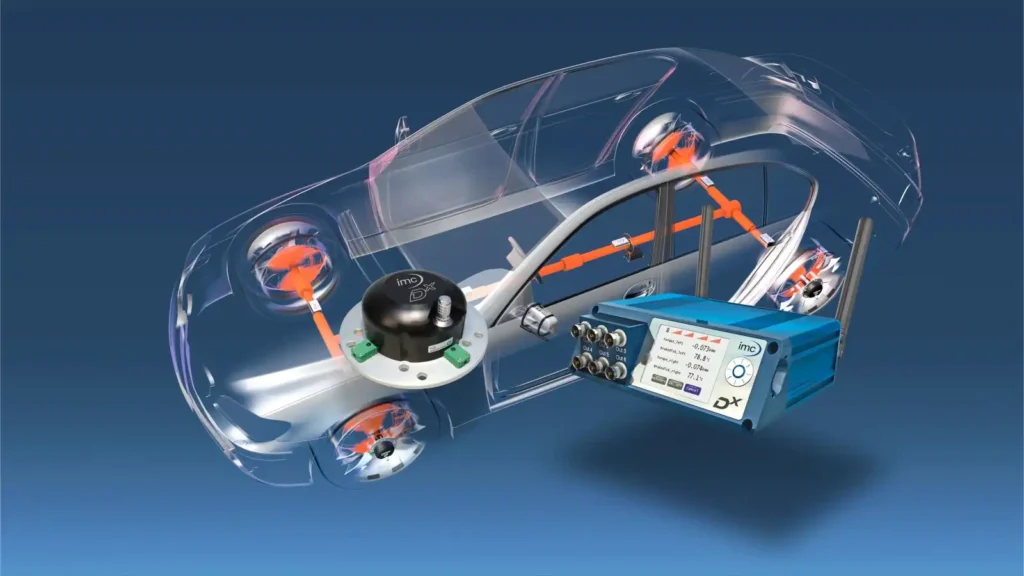

Durability in Harsh Driving Environments

The complex driving environment of an automobile places rigorous demands on sensors, and MgO is perfectly suited to meet these challenges. The intense vibrations of an operating engine and the jolts from the road require sensors to possess extreme structural stability. Armored sensors filled with MgO, manufactured through an integrated drawing process, combine flexibility with impact resistance, allowing them to withstand continuous vibrations during transit. Additionally, MgO’s excellent corrosion resistance enables it to withstand the erosion caused by oil and moisture within the engine bay, extending the sensor’s lifespan and ensuring temperature measurement reliability under various operating conditions.

Conclusion

From engine temperature monitoring in traditional fuel vehicles to lithium battery thermal management in New Energy Vehicles, Magnesium Oxide has become an indispensable core material due to its unique high-temperature resistance, insulating-conductive properties, and resilience in harsh environments. Through the empowerment of material science, this inorganic compound enables precise temperature measurement within confined spaces, building an “invisible thermal shield” for the safe and efficient operation of automobiles. It stands as a testament to how advanced material technology is driving the intelligent upgrade of the automotive industry.