In desulfurization molecular sieve catalysts for fluid catalytic cracking (FCC), magnesium oxide (MgO) plays a significant and multifaceted role, particularly in enhancing the catalyst’s resistance to metal contamination, improving desulfurization efficiency, and regulating acid-base properties. The following is an analysis of MgO’s primary functions in these catalysts:

- Regulation of Acidity/Basicity to Promote Selective Desulfurization

- Magnesium oxide is a typical alkaline oxide.

- It can neutralize strong acid sites in the molecular sieve, reducing non-selective cracking reactions (such as aromatization and coke formation).

- It helps to improve selective desulfurization reactions (especially C–S bond cleavage) rather than over-cracking, improving the quality of liquid products.

- Enhanced Resistance to Metal Contaminants (Ni, V)

- Magnesium oxide has a strong ability to capture and passivate metal contaminants.

- It can form stable compounds with Ni, V, etc., reducing their mobility and reactivity on the catalyst surface.

- It inhibits metal-catalyzed non-selective hydrogenolysis reactions, reducing gas and coke formation.

- Improved Catalyst Thermal and Structural Stability

- During high-temperature regeneration in catalytic cracking, magnesium oxide helps stabilize the molecular sieve framework structure and reduce crystal collapse.

- It exhibits a good synergistic protection effect, especially when used in conjunction with rare earth elements (such as La and Ce).

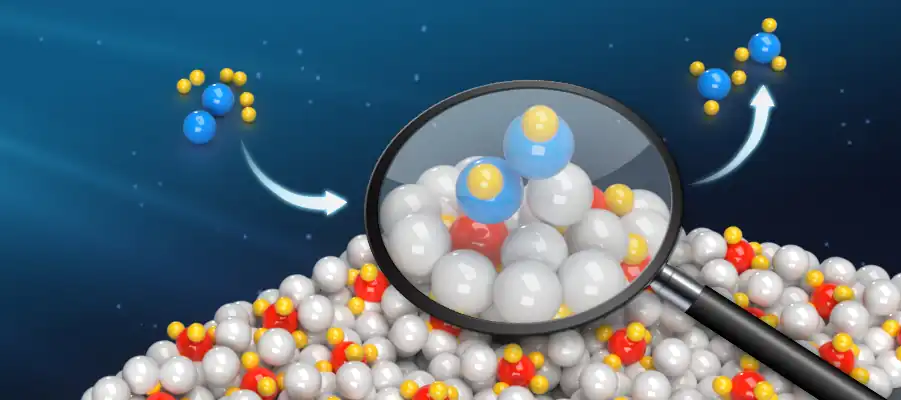

- Promotion of Sulfide Adsorption and Conversion

- Magnesium oxide can adsorb desulfurization intermediates, such as thiols and thiophene-like substances, increasing their residence time on the catalytic surface.

- This favors further C–S bond cleavage by the reactive centers, increasing sulfur removal efficiency.

- Reduced SOx Emissions from Regeneration Tail Gas

- During regeneration, magnesium oxide has a certain adsorption effect on SO₂, which can form MgSO₄.

- This helps reduce SOx emissions during the catalyst regeneration stage, improving environmental performance.

- Improved Physical Properties of the Catalyst (Specific Surface Area, Pore Structure)

- Appropriate introduction of magnesium oxide can increase the proportion of mesoporous structures, which is beneficial for the diffusion and cracking of large molecular sulfides.

- When magnesium oxide is used as an additive, it does not significantly block the pores when it has a reasonable particle size and dispersion.