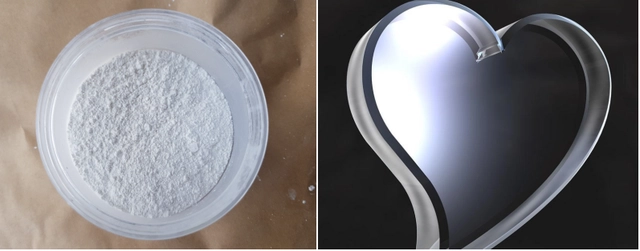

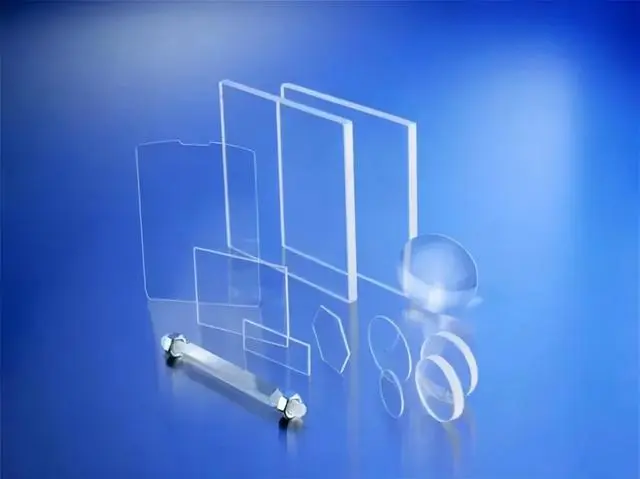

High-purity magnesium oxide powder material is an important high-temperature resistant material, and the magnesium oxide ceramic prepared from it is widely used in the field of light-transmitting materials. Transparent magnesium oxide ceramic is an optically isotropic body with the advantages of good alkali metal vapor corrosion resistance, high melting point, high thermal conductivity, small theoretical density, high insulation and high infrared transmittance. High-quality refractory transparent magnesia ceramic is a promising material, its performance is better than that of alumina ceramic, and it has a wide range of applications in the field of visible light and infrared light-transmitting materials.

1. Preparation method of high-purity MgO powder

High-purity magnesium oxide powder refers to sintered magnesium oxide with a mass fraction of MgO greater than 99% (domestic generally refers to a mass fraction of MgO greater than 98%) and a volume density greater than 3.40g/cm3. The preparation of high-purity MgO uses magnesium-containing compounds as raw materials. Some are made into light-burned magnesium oxide and then electrofused or re-fired to obtain high-purity magnesium oxide. Some are directly calcined or pyrolyzed to obtain high-purity magnesium oxide. At present, the main preparation methods include direct calcination method, brine precipitation method, brine direct pyrolysis method, and electrofusion method.

2. Different high-purity magnesium oxide powder morphologies and control processes

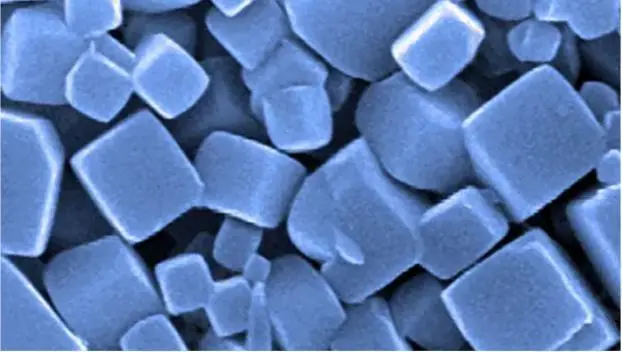

01 Cubic magnesium oxide powder

Cubic high-purity magnesium oxide powder is prepared by electrofusion method, with uniform particle size distribution, and can be used to prepare transparent magnesium oxide ceramics and electronic material fillers. In addition, the electrofusion method can also be used to prepare single crystal MgO with a purity of more than 99.9%. It is widely used as a thin film substrate for new materials, such as high-temperature superconducting films, MRAM ferroelectric films, etc.

02 Spherical magnesium oxide powder

The thermal conductivity of spherical magnesium oxide can reach 1.5 times that of spherical alumina, which greatly enhances the flexibility of material design in thermal management. It is called the “next generation thermal conductive filler” following spherical alumina.

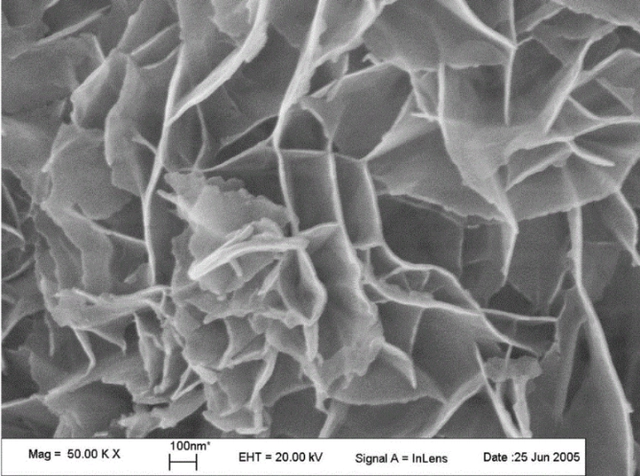

03 Flake magnesium oxide powder

The preparation of rhombohedral flaky magnesium oxide powder is based on low-grade dolomite as raw material, using brine precipitation method, preparing the precursor magnesium hydroxide through secondary acid leaching and ammonia precipitation, and then calcining to obtain a rhombohedral lamellar multi-void structure. Nano-MgO crystal, this magnesium oxide is well-crystallized, cubic crystal system, with a thickness of about 10-20nm and a maximum area of about 1μm2, a chrysanthemum-like two-dimensional rhombohedral sheet layered void structure, and is widely used in advanced ceramic materials, Cosmetics, paints, rubber fillers, catalyst carriers and other fields also have important application prospects and huge economic potential in military, quantum devices, microelectronics and other fields.

3. Research progress of magnesium oxide ceramics

At present, most of the research directions on transparent magnesium oxide ceramic technology focus on the determination of hot pressing sintering system. There are many sintering methods for transparent ceramics, including normal pressure sintering, hot press sintering, hot isostatic pressing sintering, discharge plasma sintering, etc.

4. Application of magnesium oxide ceramics

01 Transparent magnesium oxide ceramic

Transparent magnesium oxide ceramic is a kind of transparent MgO ceramic. It belongs to the cubic crystal system and has a melting point of 2800°C. It uses high-purity MgO as raw material, adds a small amount of grain growth inhibitor, and is made by hot pressing or normal pressure sintering process.

02 Magnesium oxide microwave dielectric ceramics

High-purity magnesium oxide has large surface activity and high-temperature characteristics and high purity. Therefore, magnesium oxide is generally used in ceramic filters to ensure that the filter has better conductivity, mechanical strength and high temperature resistance. Microwave dielectric ceramics are a new type of electronic material. As 5G is officially put into commercial use, 5G base stations across the country will also have continuous coverage. Microwave dielectric ceramics as filters are also widely used in the construction of 5G base stations. High-purity magnesium oxide usually affects three parameters of the filter: relative dielectric constant, quality factor, and resonant frequency temperature coefficient.

03 Preparation of molten ceramic particles

High-purity magnesium oxide and aluminum oxide are used together to prepare fused ceramic particles, which can be widely used in the field of grinding tools. Used together with rare earth oxides as sintering aids to prepare silicon nitride ceramics, it can efficiently and economically manufacture various complex-shaped products, such as cutting tools, sealing rings, bearings, nozzles and various high-temperature, wear-resistant, and resistant products. Corrosion products, etc.

04 Preparation of magnesium oxide ceramic core

The made magnesium oxide ceramic core has a service temperature of not less than 1600°C and does not react with the casting metal under high temperature conditions. The surface of the casting is smooth, which makes up for the large number of pores and pores produced in the inner hole of the casting when using a silicon-based core to cast such materials. Defects such as sand sticking; excellent dissolution property, can be well dissolved in weak acid, short core removal time, simple core removal equipment, pollution-free, safe and reliable core removal process, reducing precision casting costs; pouring hollow thin-walled castings is not easy Hot cracking occurs; the core has high dimensional accuracy; it has sufficient strength and does not deform or break during molding, transportation and furnace loading.

05 Preparation of high toughness ceramic materials

Partially stabilized zirconia ceramics with excellent mechanical properties and high temperature aging resistance are made by firing and heat-treating high-purity magnesium oxide and yttrium oxide or rare earth metal oxides as composite stabilizers. This ceramic material can be widely used as high-temperature engineering components and advanced refractory materials.