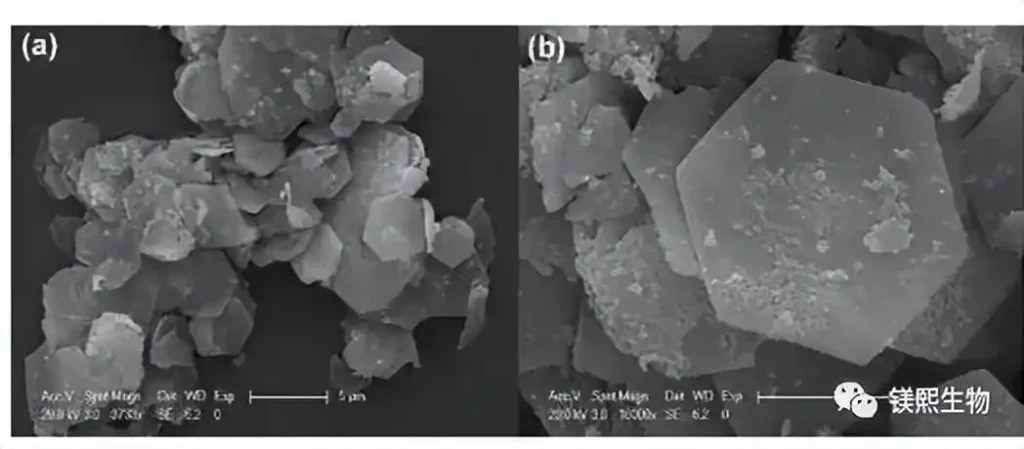

Magnesium hydroxide is a green, environmentally friendly inorganic additive flame retardant. It has the advantages of good thermal stability, non-toxicity, easy availability of raw materials, low price, and no release of toxic and harmful gases during combustion. It can be widely added to polymer materials such as plastics, rubber, and coatings to improve their flame retardant properties. Messi Biology has prepared a highly dispersed hexagonal flaky flame-retardant magnesium hydroxide with small particle size and low surface polarity, and studied its flame retardant application. The main contents include the following two aspects: First, in order to reduce the agglomeration between magnesium hydroxide particles and improve its compatibility with polymer materials, a hydrothermal method is used to prepare hexagonal flaky magnesium hydroxide with low surface polarity, good dispersion, and an average particle size of about 1μm.

Messi Biology studied the effect of hydrothermal conditions on its crystal growth, especially on the growth of the (001) crystal plane with weaker polarity. It was found that reducing the initial particle size of the raw materials and the solid content of the feed, increasing the OH– concentration in the hydrothermal medium and the hydrothermal temperature, and extending the hydrothermal time are all beneficial to crystal growth. However, when the OH– concentration in the medium is greater than 8 mol/L or the hydrothermal time exceeds 10 h, the growth direction of the crystal will be changed, and the growth of the (001) crystal plane will be shielded. The growth process is explained by the theory of negative ion coordination polyhedron growth unit. On the basis of optimizing the experimental conditions, the preparation of hexagonal flake magnesium hydroxide was enlarged, and the optimal hydrothermal conditions at two high feed concentrations of 20wt.% and 30wt.% were investigated. Second, the application of magnesium hydroxide flame retardant was studied. Irregular crystals, irregular crystals modified by stearic acid, and hexagonal flake magnesium hydroxide were added to polyethylene to investigate their effects on the mechanical properties, flame retardancy, rheological properties, and crystallization behavior of polyethylene materials.

Magnesium hydroxide can increase the oxygen index of polyethylene from 19.2% to 22.6%, enhancing its flame retardancy. And hexagonal flake magnesium hydroxide can effectively improve the tensile strength of the material, but the elongation at break decreases seriously, from 231.65% to 28.78%, while modified magnesium hydroxide has little effect on the mechanical properties of polyethylene. Since magnesium hydroxide has a heterogeneous nucleation effect on polyethylene, the crystallization rate of the material is accelerated, and the crystallinity decreases with the increase of magnesium hydroxide addition. In addition, the addition of different types of magnesium hydroxide will enhance the pseudoplasticity of the material and reduce the rheological properties.