The main processes for preparing light magnesium carbonate from dolomite are as follows:

1. Calcination method

The calcination method is to decompose dolomite into magnesium oxide and carbon dioxide at high temperature, then hydrate the magnesium oxide into magnesium hydroxide, and then undergo carbonization to produce light magnesium carbonate. The process flow of the calcination method is as follows:

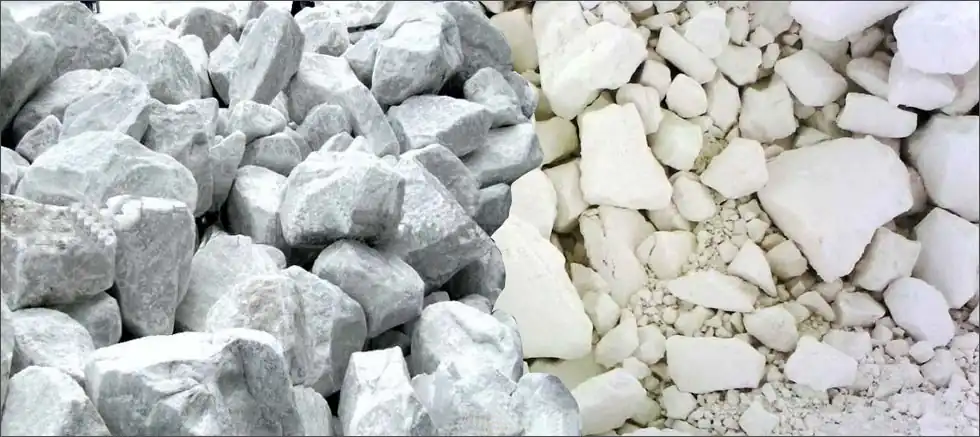

Dolomite crushing: crush dolomite into particles smaller than 10 mm.

Calcination: Calculate dolomite at 900-1100°C for 2-3 hours to decompose it into magnesium oxide and carbon dioxide.

Hydration: Hydrate the calcined magnesium oxide in water to form magnesium hydroxide slurry.

Carbonization: Pass carbon dioxide into the magnesium hydroxide slurry to carbonize it into light magnesium carbonate.

The calcination method is the most commonly used method for producing light magnesium carbonate and has the advantages of simple process and low production cost. However, the light magnesium carbonate produced by the calcination method has coarse particle size, small specific surface area and low activity.

2. wet method

The wet method is to dissolve dolomite in acid to generate a soluble magnesium salt solution, and then produce light magnesium carbonate through evaporation crystallization, precipitation and other methods. The wet process process is as follows:

Dolomite grinding: grind dolomite into powder smaller than 325 mesh (44μm).

Dissolution: Dissolve dolomite powder in hydrochloric acid or nitric acid to generate a soluble magnesium salt solution.

Purification: Purify the magnesium salt solution to remove impurities.

Precipitation: Add alkali solution to the magnesium salt solution to precipitate it into magnesium hydroxide.

Carbonization: Pass carbon dioxide into the magnesium hydroxide slurry to carbonize it into light magnesium carbonate.

The light magnesium carbonate produced by wet method has fine particle size, large specific surface area and high activity, but the process is complicated and the production cost is high.

3. gas phase method

The gas phase method is to react dolomite with hydrogen chloride at high temperature to generate magnesium chloride gas, then hydrolyze the magnesium chloride gas into magnesium hydroxide, and then undergo carbonization to produce light magnesium carbonate. The process flow of the gas phase method is as follows:

Dolomite crushing: crush dolomite into particles smaller than 5 mm.

Chlorination: React dolomite with hydrogen chloride at 600-800°C to generate magnesium chloride gas.

Hydrolysis: Pass magnesium chloride gas into water to hydrolyze it into magnesium hydroxide.

Carbonization: Pass carbon dioxide into the magnesium hydroxide slurry to carbonize it into light magnesium carbonate.

At present, the calcination method and wet method are mainly used to produce light magnesium carbonate. With the advancement of science and technology, the gas phase method will be more and more widely used.