At present, the methods for preparing spherical magnesium oxide mainly include: flame melting method, jetting method, template method, aerosol decomposition method, sol-gel method, hydrothermal method, drip ball method, homogeneous precipitation method, and ball milling method.

Flame melting method Flame melting method is to directly spray magnesium oxide powder with irregular appearance into the flame, so that the magnesium oxide powder can melt into balls in the flame. The flame melting method used by Ya’an Baitu uses natural gas as fuel, supplemented by oxygen combustion, and when the powder passes through the high-temperature zone of the flame, it melts into a ball.

Preparation of spherical magnesium oxide by jetting method refers to the transformation of the phase in a short time, and the product is spherical by the action of surface tension. According to the characteristics of phase transformation, the spray method can be divided into spray pyrolysis method and spray drying method. and jet melting method.

Schematic diagram of spray thermal decomposition and plasma experimental device Spray pyrolysis method is to atomize the configured precursor solution into small droplets and then enter a high-temperature reactor and then undergo a physical and chemical reaction to form spherical particles. The spray drying method is the process of converting the water-based suspension (slurry) into dry particles (raw material) by spraying the fluid feed into a heated air stream. By taking rapid heat and mass transfer, hollow particles are finally generated. or solid sphere. The jet melting method is a method of quickly melting magnesium oxide by induction ions such as radio frequency, and then quickly cooling it through injection to obtain spherical magnesium oxide.

The template method is a core template with colloidal particles with spherical morphology as the precursor. It undergoes a series of processes such as assembly, adsorption, sol-gel action, and precipitation reaction. It wraps a layer of core/shell outside the core template. The structured microspheres are then removed by solvent dissolving the nucleus or high-temperature calcining, and finally hollow microspheres are obtained. It can effectively control the morphology of the material, and according to the properties of the material, it can also be divided into hard template method and soft template method.

The preparation of spherical magnesium oxide is mainly made of liquid magnesium alkoxide as raw material. It uses its physical and chemical properties to hydrolyze with water vapor during atomization process, and then dry or pyrolyze at high temperatures, achieving gas phase conversion to The liquid phase eventually forms a solid phase magnesium oxide particles or gas phase directly converts to solid phase magnesium oxide. It can be mainly divided into the following four steps: atomization reaction of magnesium alkoxide raw materials; formation of aerosols; hydrolysis of aerosols and formation of solid particles; recovery of generated solid particles.

The preparation of spherical magnesium oxide by sol-gel method is mainly based on the phase change of the sol obtained by metal alcohol oxygen compounds or organometallic precursors. The solution containing suspended particles is synthesized in the solution, polymerized at low temperature to form a wet gel, and then the gel is dried to remove the solvent, and the product is obtained after a series of heat treatments. Nowadays, most scholars combine sol-gel method with emulsion method to prepare spherical magnesium oxide with better morphology.

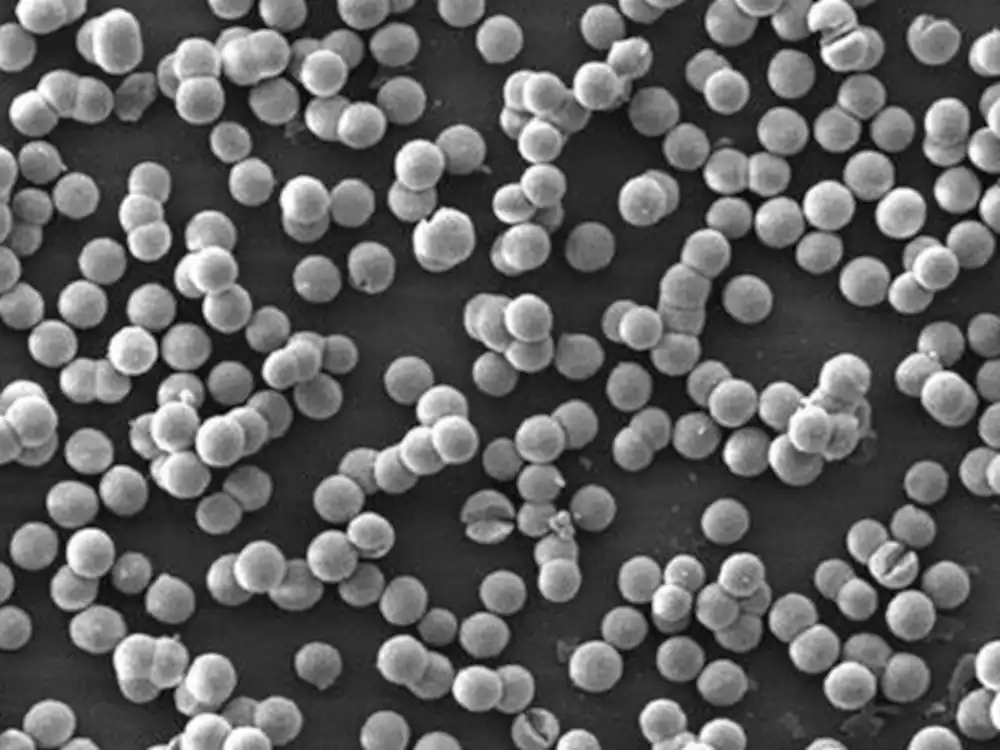

The preparation of spherical magnesium oxide by hydrothermal method is made of magnesium salt as raw material, generally using aqueous solution as medium, in a closed high-pressure reactor, heat-raising and forming a high-temperature and high-pressure reaction environment, so that the substance can be qualitatively grown and synthesized during the dissolution and recrystallization process. Intact spherical magnesium oxide particles

The preparation of spherical magnesium oxide by drip ball method is improved on the basis of the sol-emulsion-gel method. The emulsion process technology is used in the aging stage, and the product magnesium oxide directly enters the oil layer, forms a sol through surface tension, and then puts it in A gel is formed in the aqueous ammonia solution, and finally dried and calcined to obtain spherical magnesium oxide powder particles.

The homogeneous precipitation method prepares spherical magnesium oxide by adding a precipitant to the magnesium salt solution to form insoluble hydroxide precipitation. During the precipitation and formation process, the crystal nucleus undergoes a process of aggregation, growth and precipitation after formation. Generally, the reactions occurring in this process are in a non-equilibrium state. In order to promote the fine and uniform precipitation particles to remain in an equilibrium state for a long time, it is usually chosen to reduce the concentration of the precipitant in a homogeneous solution, or to make the precipitation reaction slow.

The ball milling method mainly involves putting raw materials into a ball mill, and using the impact force and impact force at high speed to crush the raw materials into ultra-fine powder. At the same time, rotating at high speed will generate a lot of heat, resulting in the generation of chemical reactions, thereby generating new substances. . The ball milling method prepares ultrafine magnesium oxide powder, which is simple to operate, low cost and high yield, but it also has limitations, such as uneven product particle size distribution, mechanical limitations of the minimum particle size, and it is difficult to obtain spherical particles.