I. Product and Technology Introduction:

Ultra-high purity magnesium oxide is a new type of functional fine inorganic materials, widely used in electronic components, advanced ceramic materials and other fields; for example, the MgO dielectric protection film is a new generation of plasma flat-panel displays (PDPs) in the key components, its performance directly affects the PDP’s operating characteristics and life expectancy, the general requirements of the MgO purity requirement is greater than 99.99%, and the total amount of impurity elements shall not exceed 100ppm. Although China’s magnesium resource reserves ranked first in the world, but there is a lack of large-scale production of high-purity magnesium oxide key technology, domestic mass production of MgO purity is usually below 99.9%, which limits its application in the field of high-tech.

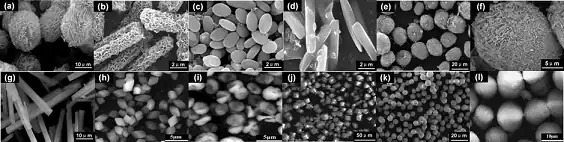

This project invented a simple preparation of high-purity MgO products technology, can be used for the production of PDP display media protection film raw materials, and the production of magnesium oxide single crystal raw materials, product purity of 99.99% or more; invented dense stacking of high-purity magnesium carbonate preparation of electrofusion magnesium oxide technology; invented Ca, Sr, Sc doped magnesium oxide material preparation process; invented magnesium aluminum, magnesium boron, and other composite functional oxides Material preparation technology; prepared hollow tube, square, fiber, multilayer sheet, flower and other morphology of magnesium oxide, magnesium carbonate, basic magnesium carbonate and basic magnesium sulfate micro-nanomaterials; its raw materials are readily available, high purity products, low cost, with the value of industrialized applications.

II. Performance requirements

High purity: the purity of magnesium oxide is usually required to reach 99.9% and above. High purity is to avoid the adverse effects of impurities in the plasma discharge process, such as impurities may lead to unstable discharge, reduce the luminous efficiency or cause abnormalities in the screen display and other issues.

Appropriate particle size distribution: the size and distribution of magnesium oxide particles will affect its coating performance and discharge performance in PDP. Generally need to have a fine and uniform particle size, so that it can be more evenly coated on the surface of the electrode and other components, conducive to the formation of a stable plasma discharge environment.

Good crystal structure: Magnesium oxide with a specific crystal structure, such as the cubic crystal system, performs better in PDP applications. Appropriate crystal structure helps the transmission of electrons and the interaction with the plasma, thus guaranteeing the normal display function of the monitor.

III. Application Advantages

As a protective layer: In PDP, high purity magnesium oxide can be coated on the electrode surface to form a protective film. This protective film can prevent the electrode from corrosion and sputtering in the plasma discharge process, prolong the service life of the electrode, and thus improve the overall reliability and stability of the PDP.

Improvement of discharge performance: As magnesium oxide has certain dielectric properties and electron transport properties, it can optimize the conditions of plasma discharge. Make the discharge more uniform and stable, thus improving the luminous efficiency of PDP and the quality of the screen display, such as making the color more vivid, more uniform brightness.

IV. The preparation of the difficulties

Purity control: to achieve the high purity standards required for PDP, in the preparation process requires strict control of the purity of raw materials and various preparation to avoid impurities mixed. For example, in the preparation of chemical precipitation method, the purity of the precipitant and the cleanliness of the reaction vessel have high requirements.

Particle size and crystal structure regulation: it is not easy to precisely regulate the particle size distribution of magnesium oxide and form an ideal crystal structure. Different preparation methods, such as chemical precipitation method, hydrothermal synthesis method, etc., need to realize effective control of particle size and crystal structure through fine adjustment of reaction conditions (such as temperature, time, pH value, etc.).

In conclusion, high-purity magnesium oxide for PDP is one of the key materials to guarantee the good performance and long-term stable operation of PDP, and its preparation technology is constantly being developed and improved to better meet the needs of the PDP industry.

V. the scope of application and production conditions:

The present invention proposes a new practical technology to make MgO products with a purity of more than 99.99% and a particle size between 50 nm and 10 μm; its raw materials are easy to obtain, the product purity is high, the cost is low, and it has the value of industrialized application.

VI. with the picture: