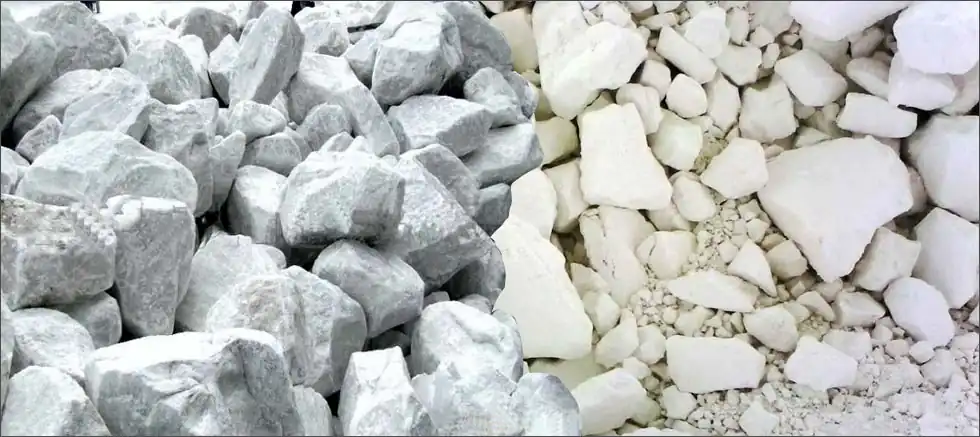

Dolomite is a natural carbonate mineral, the main components of which are calcium carbonate (CaCO₃) and magnesium carbonate (MgCO₃). Through a specific chemical treatment process, nano-scale magnesium hydroxide (Mg(OH)₂) can be extracted and prepared from dolomite. Due to its unique properties, this nanomaterial has broad application prospects in many fields, including but not limited to catalysts, flame retardants, environmentally friendly materials, and composite material reinforcements.

Preparation method

1. Acid leaching method: Dolomite is first pretreated with acid (usually hydrochloric acid) to dissolve the carbonate therein to form a solution containing magnesium ions. Then the pH of the solution is adjusted to alkaline (such as pH=12) to convert the magnesium ions into magnesium hydroxide precipitation. This process is usually carried out at room temperature, and the yield and morphology of magnesium hydroxide can be optimized by controlling the pH and aging time.

2. Carbonization-ammoniation method: After the dolomite is carbonized, ammonia water is added for ammoniation reaction to form magnesium hydroxide. This method can control the morphology and size of the product. By adjusting the carbonization time and temperature, ammonia concentration, and hydrothermal synthesis conditions, magnesium hydroxide with different morphologies can be obtained.

3. Pyrolysis: Dolomite is heated to high temperature to decompose and generate magnesium oxide and carbon dioxide. Magnesium oxide then reacts with water to generate magnesium hydroxide.

Influencing factors

• pH value: A higher pH value is conducive to the precipitation of magnesium hydroxide, but too high a pH value may affect the aggregation state and crystallinity of the particles.

• Aging time: Appropriate aging time helps to improve the crystallinity and particle size distribution of magnesium hydroxide. Too long or too short an aging time is not conducive to obtaining uniform and well-dispersed nanoparticles.

• Reaction temperature: Temperature has a significant effect on the reaction rate and product morphology. The appropriate temperature range helps to control the crystallinity and morphology of magnesium hydroxide.

• Raw material purity: Impurities in dolomite may affect the purity and performance of the final product.

• Stirring speed: An appropriate stirring speed can ensure that the reactants are mixed evenly, promote the reaction, and avoid particle agglomeration.

• Addition of crystal habit modifiers: The addition of certain chemicals can change the crystal growth direction of magnesium hydroxide, thereby affecting its morphology and performance.

By finely controlling the above factors, nano magnesium hydroxide with excellent performance and controllable morphology can be prepared.