Silane Coupling Agent Modified Hexagonal Flake Magnesium Hydroxide Flame Retardant is a method of combining a silane coupling agent with hexagonal flake magnesium hydroxide (Mg(OH)₂) through a specific process designed to enhance the flame retardant properties of Mg(OH)₂ and to improve its dispersion in polymer substrates. Some of the key points and preparation methods are described below:

Preparation method :

Two-step method : First, wet magnesium hydroxide solids were prepared using a sodium hydroxide precipitation-hydrothermal treatment process. Then, the surface of magnesium hydroxide was modified by silane coupling agent KH550, and the specific process conditions were as follows: hydrothermal temperature of 160 ℃, hydrothermal time of 6 hours; surface modification temperature of 80 ℃, and the optimal amount of silane coupling agent was 5.0% of the theoretical amount of magnesium hydroxide.

High-speed jet pulverization: The raw magnesium hydroxide powder is driven to high-speed movement by dry oil-free compressed air to form a high-speed jet, so that the raw powder is crushed by collision and friction, and the fine magnesium hydroxide powders with a particle size of D50 of 3.5 μm-4.5 μm are collected. The crushed magnesium hydroxide fine powder is stirred in the preheated high churning machine, and at the same time, silane coupling agent is sprayed to carry out the modification treatment, and then it is subjected to the coating treatment and sieving treatment.

Modification effect :

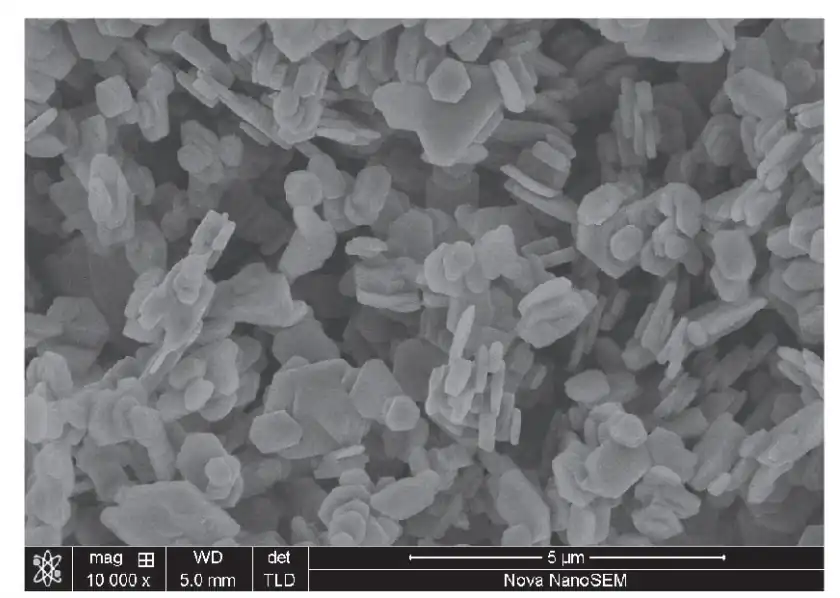

Surface modification: silane coupling agent is chemically adsorbed on the surface of magnesium hydroxide powder, which reduces its surface polarity, and thus improves the dispersibility and hydrophobicity. The modified magnesium hydroxide has high crystallinity, regular grain shape, flaky, small particle size (average particle size of about 300nm) and narrow particle size distribution.

Flame retardant performance: The composite material composed of modified magnesium hydroxide and EVA resin has very good flame retardant performance, with an oxygen index of 29.9.

Interfacial compatibility: Through the use of different silane coupling agents (such as γ-aminopropyltriethoxysilane, γ-methacryloyloxypropyltrimethoxysilane, etc.), it can improve the inorganic/organic interfacial compatibility between magnesium hydroxide and polymer substrate, so as to improve the mechanical properties and flame retardancy of the composite material.

Applications :

Silane coupling agent modified magnesium hydroxide flame retardant is suitable for the flame retardancy of various polymer substrates, such as polypropylene, EVA, etc., because of its excellent flame retardancy and environmental protection characteristics. By optimizing the preparation process and the type of modifier, a balance between efficient flame retardancy and material properties can be achieved.

Suggestion

Selection of appropriate silane coupling agent: Select the appropriate type and dosage of silane coupling agent according to the specific needs of the application, in order to achieve the best flame retardant effect and material properties.

Optimize the preparation process: Strictly control the process parameters such as hydrothermal temperature and time, surface modification temperature, etc., to ensure that the crystallinity and particle size distribution of the modified magnesium hydroxide reach the best state.

Test and Evaluation : The modified magnesium hydroxide flame retardant was subjected to comprehensive performance tests, including flame retardant properties, mechanical properties, thermal stability, etc., to verify its effectiveness in practical applications.

The silane coupling agent modified hexagonal flake magnesium hydroxide flame retardant prepared by the above method can improve its dispersion and compatibility in polymer substrate while improving its flame retardant property, which has a wide range of application prospects.