Introduction

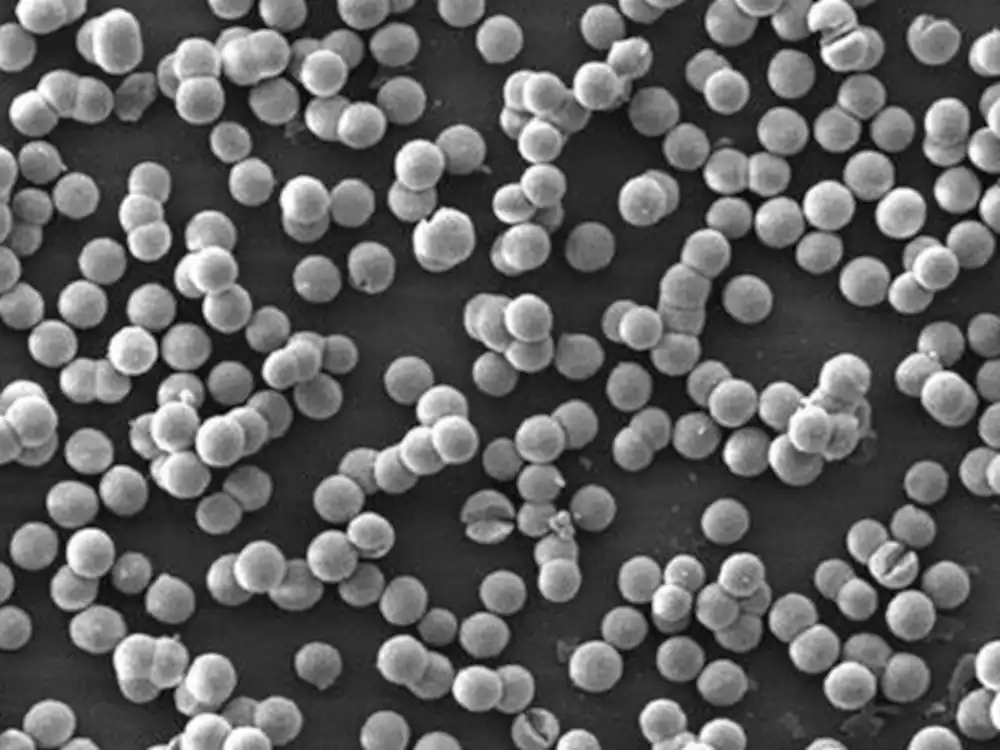

A method for preparing spherical magnesium oxide particles with a large specific surface area, according to the stoichiometric ratio of each element, weigh the corresponding magnesium acetate Mg(CH3COO)2 and acetamide C2H5NO; then weigh 0.1%~3% of the total weight of the above drugs respectively. The weighed magnesium acetate Mg(CH3COO)2 and acetamide C2H5NO, surfactant and polyethylene glycol are fully mixed in ethanol or ethylene glycol ligand, the mass ratio of reactant to ligand is 1:5‑8, and then placed in a magnetic stirrer for constant temperature stirring, the stirring temperature is 40°C, the stirring time is 8‑10h, until the reactant and the ligand are fully mixed. The above product is placed in a drying oven at 60°C for drying to obtain a precursor powder; the precursor powder is calcined in a muffle furnace, the calcination temperature is 250‑350°C, and the combustion time is 2-5 hours, and the target product is obtained.

Technical introduction

MgO is an important chemical raw material, which is widely used in catalysis, antibacterial, refractory and superconducting materials, and can also be used as a filler for paper, cosmetics, etc. Due to the unique volume effect and surface effect of nanomaterials, the composite materials formed by nano-MgO and polymers have good microwave absorption performance. In addition, MgO nanoparticles have high surface activity and show many chemical properties different from bulk materials in catalysis and adsorption, which makes them have a wide range of potential applications in these fields. At the same time, my country’s magnesium resources are abundant and low in cost, which makes MgO nanoparticle materials have significant practical value. The morphology of nano-magnesium oxide particles will have a huge impact on their surface adsorption and catalytic properties. Therefore, it is of great significance to develop a method for MgO nanoparticle materials with simple operation, good particle morphology, uniform size and good dispersibility. At present, the preparation methods of MgO nanoparticle materials mainly include room temperature solid phase chemical reaction method, precipitation method and electrochemical reaction method. These preparation methods have their own advantages and disadvantages, such as the solid phase method is simple to operate but the particle morphology is not good, the precipitation method has good morphology but the process is complicated, and the electrochemical method has high cost. Therefore, the development of new methods for preparing MgO nanoparticles is still very attractive. So far, there has been no report on the preparation of spherical MgO nanoparticles by soft template method.

Preparation method

A method for preparing spherical magnesium oxide particles with large specific surface area, characterized in that the specific steps are as follows: (1) According to the stoichiometric ratio of each element, weigh the corresponding magnesium acetate Mg(CH3COO)2 and acetamide C2H5NO; then weigh 2% of the total weight of the above drugs, sodium tetrapropylene benzene sulfonate and polyethylene glycol 1000; (2) Preparation of precursors: weigh the weighed magnesium acetate Mg(CH3COO)2 and acetamide C2H5NO, sodium tetrapropylene benzene sulfonate and polyethylene glycol 800 are fully mixed in anhydrous ethanol ligand, and the mass ratio of the reactant to the anhydrous ethanol ligand is about 1:7. Then, the mixture is placed in a magnetic stirrer for constant temperature stirring at a temperature of about 40°C for about 8 hours until the reactant and the ligand are fully mixed. (3) Drying: The above product is placed in a drying oven and dried at 60°C to obtain a precursor. (4) Calcination: The precursor is calcined in a muffle furnace at a calcination temperature of 300°C for 4 hours to obtain the target product.