Abstract

The present invention discloses a preparation method of high-purity large-size magnesium oxide single crystal, which belongs to the field of crystal growth technology. The method firstly purifies magnesite to get high purity re-fired magnesium oxide; re-fired magnesium oxide is crushed, magnetically selected, and sieved to get graded magnesium oxide powder; according to the principle of stacking of the maximum density, the graded magnesium oxide powder is mixed in grades, and then 10-50 tons of the mixture are loaded into the single crystal growth furnace body at one time; at a temperature of 2800-3500 ℃, the current of 20,000 amps under the condition of smelting for 20~50 hours; after natural cooling, the outer polycrystalline magnesium oxide layer is stripped to get the single crystal. 50 hours; natural cooling after stripping the outer polycrystalline magnesium oxide layer, to get magnesium oxide single crystal block, and then through the sorting, you can get high purity large size magnesium oxide single crystal. The method of the present invention can produce high purity (≥99.99%), large size (≥2 inches) magnesium oxide single crystals, and the method of the preparation process is simple, the source of raw materials and equipment and process conditions of the requirements of the low, is conducive to the popularization of application.

Description

A method for the preparation of high purity and large size magnesium oxide single crystals

Technical Field

The present invention belongs to the field of materials science and technology, and relates to the science and technology of crystal growth, especially the preparation method for producing high purity (≥99.99%), large size (≥2 inches) magnesium oxide (MgO) single crystals from low grade magnesite.

Background technology

Magnesium oxide single crystal has excellent high and low temperature resistance (-270 ℃ ~ 2800 ℃), high purity (≥ 99.95%), corrosion resistance, excellent insulating properties, good thermal conductivity, good transmittance (light wavelength of 200-2000nm transmittance of 85 ~ 99%, light wavelength of 2.5-7μm transmittance of more than 92%) and other excellent characteristics, in high temperature superconductivity, semiconductor, infrared It has been widely used in high-temperature superconductivity, semiconductor, infrared sensor, laser, ultra-high-temperature materials, window materials, aerospace, medical equipment, plasma display and other fields. With the continuous progress of science and technology, especially the development of optoelectronic industry and wireless communication, the single crystal magnesium oxide needs more and more, the development prospect is very broad.

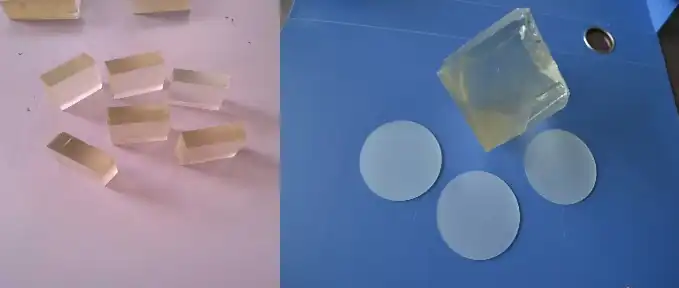

In various fields of application, the size of magnesium oxide single crystal is generally required between 5×5×5mm-100×100×100mm, or even larger. And the melting point of magnesium oxide is above 2800 ℃, the boiling point is 3600 ℃, so to get large size, high purity magnesium oxide single crystal, the selection and control of raw materials is very strict requirements. Secondly, to get the high quality crystals with perfect growth and large size, the whole smelting process is very time-consuming and energy-consuming, which will be up to dozens of hours. In this process, how to adjust and control the current and voltage, so that the smelting process can operate safely and stably, the electronic control system has undertaken the most difficult task. Also, in the case of the previous two conditions, how to make the raw materials fully melted, impurities precipitation, so that the nucleus stable generation, the growth of large-size crystals is also crucial. This process is completed in the furnace temperature and pressure is extremely high state, so the smelting process design and operation is the key elements of the production of single crystals. Only by rationally optimizing these manufacturing process technologies can we ultimately obtain the desired large-size magnesium oxide single crystals.

In view of the excellent characteristics and application background of magnesium oxide single crystal, some developed countries have been researching the production and application technology of magnesium oxide single crystal, and at present the more mature ones are only a few countries such as Japan, South Korea, Israel, the United States and so on have a small amount of production. However, most of the magnesium oxide monocrystal produced in these countries is seawater magnesium sand as raw material, this raw material contains boron and chloride ions, thus affecting the magnesium oxide monocrystal transmittance, color and other qualities (such as Japan’s Open License Bulletin 11-349399, 1999.12.21; Invention Patent 200580045352.8; Toteho company has products for sale are used seawater magnesium to (production). In recent years, China has also carried out some research in this area, and relevant invention patents have appeared. These patents, on the one hand, need to choose the higher purity of magnesite as raw materials, on the other hand, need to use special manufacturing equipment (such as invention patent 200410021334.3, 200510046477.4).

Contents of the invention

The purpose of the present invention is to provide a method for the preparation of high-purity large-size magnesium oxide single crystals using inexpensive magnesite as the raw material and static smelting method, the method of the present invention can produce high-purity (≥99.99%), large-size (≥2 inches) magnesium oxide (MgO) single crystals, and the preparation process of the method is simple, with low requirements for the raw material source and the equipment and the process conditions, which is conducive to the popularization of the application.

In order to realize the above purpose, the technical solution adopted in the present invention is:

A method of preparing a high-purity large-size magnesium oxide single crystal, the method comprising the following steps:

(1) Magnesite (magnesium carbonate mass content ≥45%) is purified and purified to obtain high-purity refired magnesium oxide (magnesium oxide mass content >99.9%);

(2) The refired magnesium oxide produced in step 1) is crushed, magnetically selected, and sieved to obtain graded (different particle size ranges) magnesium oxide powders with particle sizes of 4-6mm, 3-4mm, 2-3mm, 1-2mm, and 0.5-1mm, respectively, and the magnesium oxide powder with a particle size of 0.5mm or less is removed;

(3) In accordance with the principle of stacking with maximum density, mix the graded magnesium oxide powders in grades (the mass content of magnesium oxide powders in each grade ranges from 10~30%) to obtain the mixture, and then load 10~50 tons of the mixture into the single-crystal growth furnace body at one time (the size of the furnace chamber φ3m×2.7m);

(4) pre-buried in the furnace chamber into the graphite electrode 2 ~ 3; mixed material loaded into the furnace body after power heating, at a temperature of 2800 ~ 3500 ℃, the current of 20,000 amperes under the conditions of smelting 20 ~ 50 hours; and then cut off the power, the natural cooling of 100 ~ 300 hours; finally, peeling off the outer layer of polycrystalline magnesium oxide layer, magnesium oxide monocrystalline blocks can be obtained, and then through the sorting, you can get the size of 10mm or more! Then through sorting, we can get the high purity and large size magnesium oxide single crystal.