In the process of producing light magnesium carbonate by carbonization, the carbonation reaction is to make Mg(OH): generate Mg(HCO3): and enter the liquid phase, and at the same time generate calcium carbonate precipitation solid phase. After filtration and separation, the filtrate is weighed as magnesium water, and pyrolysis is carried out at 90~105℃ to generate light magnesium carbonate precipitation. The precipitation has a fine particle size and the filter cake moisture content is as high as about 85% during filtration, and the energy consumption is high during drying. In order to reduce energy consumption and improve product application performance, low-temperature pyrolysis is adopted in the pyrolysis process, and air is introduced to reduce the CO: partial pressure during the pyrolysis process, so that the crystal shape of light magnesium carbonate generated by the pyrolysis reaction is needle-shaped, and this light magnesium carbonate is called needle-shaped light magnesium carbonate. Needle-shaped light magnesium carbonate is easy to filter, saving about 1/2 of the filtration time, reducing the moisture content by more than 10 percentage points, greatly reducing the drying energy consumption, and having good economic benefits.

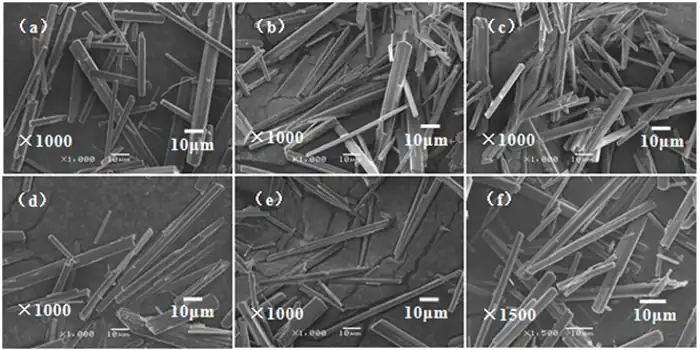

Needle-shaped light magnesium carbonate is a white needle-shaped crystal with an aspect ratio of about 10~30. Non-toxic and tasteless. Its chemical composition is a hydrate of magnesium carbonate and magnesium hydroxide, which is relatively stable in the air. Its molecular formula varies slightly with the changes in production raw materials and production conditions. It is slightly soluble in water, weakly alkaline, easily soluble in dilute acid, and emits carbon dioxide by foaming and decomposition when exposed to acid. It loses water first when heated and calcined, and then decomposes to generate MgO and CO2. Needle-shaped light magnesium carbonate is mainly used as a rubber filler and reinforcing agent. Because its crystal shape is needle-shaped, it is easy to combine with rubber. If its particle size and aspect ratio are properly controlled, its refractive index is close to that of rubber, and its reinforcement and transparency are good, which can improve the rigidity of rubber and improve flexibility. In addition, it can also be used in food, cosmetics and medicine.

The production methods of needle-shaped light magnesium carbonate include: dolomite carbonization method, magnesite carbonization method, brine-lime (or dolomite) carbonization method, asbestos tailings carbonization method, etc. Except for the different pyrolysis process conditions, the other process processes are the same as the production process of light magnesium carbonate, the production method and production principle of light magnesium carbonate. In the process of preparing light magnesium carbonate by carbonization, only the process conditions and equipment of the pyrolysis process are appropriately modified, and the pyrolysis temperature is reduced from the original 95-105℃ to below 50-60℃, which greatly saves energy consumption. At the same time, needle-shaped light magnesium carbonate is generated, which is easy to filter and reduces the water content of the light magnesium carbonate filter cake, thereby reducing the energy consumption of the drying process, improving the product quality, and adding new magnesium carbonate varieties. It is a process technology that achieves multiple goals at one stroke. It is also a new technology with low investment, quick results, energy saving and consumption reduction, and obvious economic benefits.